In a world where efficiency often reigns supreme, the journey from paddy to plate is one that deserves closer scrutiny. At the heart of this process lies a powerful yet often overlooked catalyst: the rice milling machine. As staple grains nourish billions, the technology behind their transformation plays a pivotal role in ensuring quality, reducing waste, and maximizing yield. This article delves into the essential role of rice milling machines, exploring how these innovative devices unlock efficiency within the agricultural sector, enhance food security, and support economies across the globe. Join us as we uncover the intricate mechanics and significant impacts of rice milling machines, and reveal how they stand as silent guardians in the quest for sustainable and efficient food production.

Understanding the Mechanisms Behind Rice Milling Machines

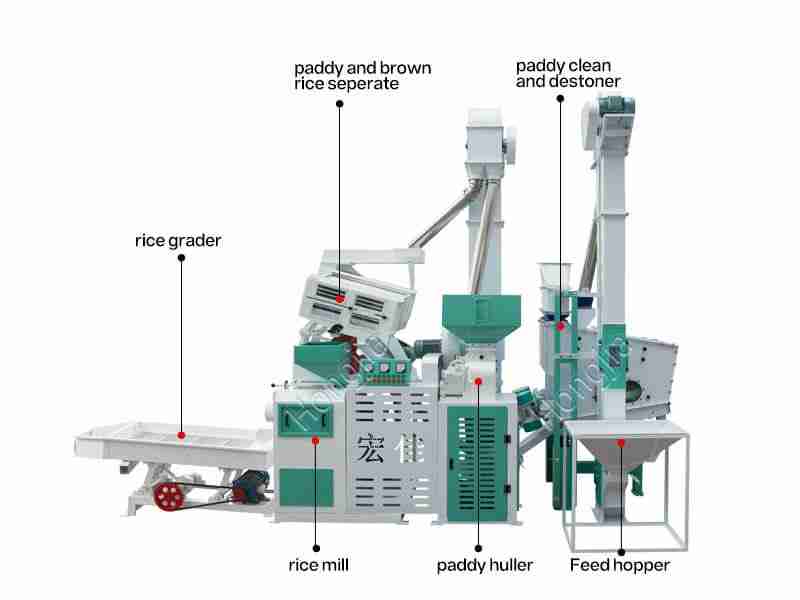

Rice milling machines operate through a series of intricate processes that work in harmony to transform raw paddy into polished rice. The primary mechanisms involve a combination of dehusking, whitening, and polishing stages, each designed to improve the quality of the rice while minimizing waste. During the dehusking phase, the outer husk is removed using rubber rolls that are adjusted for different types of paddy. This is crucial as it ensures that the majority of the grain remains intact, preserving its nutritional value and overall quality. Following dehusking, the grain enters the whitening phase, where steel huller machines polish the rice by removing the bran layer—a process that demands precision and control to avoid excessive grain damage. Each stage contributes significantly to the overall yield and quality of the final product.

A vital component of modern rice milling machines is their automation and control systems, which enhance efficiency and consistency. Advanced sensors monitor the moisture content, and weight of the paddy, adjusting the machinery’s operations in real time to ensure optimal performance. Among these are features like pre-cleaners that remove unwanted materials, and destoners that separate stones from the grain. This multi-faceted approach not only improves the final product’s quality but also reduces labor costs and manual errors. Here are some key mechanisms at play:

- Dehusking: Removal of the outer husk using rubber rolls.

- Whitening: Polishing of the rice to enhance appearance using steel hullers.

- Polishing: Final refinement to improve texture and luster.

- Mechanical Automation: Use of sensors for real-time adjustments and monitoring.

These integrated systems create a production environment that maximizes throughput while maintaining product integrity. The efficiency of rice milling machines is often quantifiable through specific metrics. The following table summarizes the key advantages that these machines have introduced to rice production:

| Advantages | Benefits |

|---|---|

| High Yield | Maximizes output per unit of paddy processed. |

| Quality Control | Ensures uniform grain size and texture. |

| Reduced Labor | Minimizes the need for manual intervention. |

| Energy Efficiency | Optimizes energy usage during production. |

Maximizing Yield: Best Practices for Optimal Milling Efficiency

To achieve maximum yield in rice milling, understanding the intricacies of your milling machine is essential. First and foremost, regular maintenance ensures that machines operate at peak performance. This includes tasks such as cleaning the machines of debris and residue, routinely checking and replacing worn parts, and monitoring calibration settings to ensure optimal operation. By implementing a proactive maintenance plan, mill operators can minimize downtime and enhance efficiency. Additionally, employing the right milling techniques tailored to the specific rice variety will not only improve yield but also improve the quality of the final product.

Furthermore, investing in high-quality milling equipment and technology can significantly impact efficiency. The following best practices can help streamline processes and maximize output:

- Choose the right milling machine: Different machines are designed for various types of rice; selecting the appropriate one can reduce breakage and enhance yield.

- Optimize milling parameters: Adjust settings like moisture content and milling pressure according to rice quality to achieve the best results.

- Implement a quality control system: Regularly sample and analyze rice output to identify areas for refinement and ensure high-quality grades.

- Train staff effectively: Comprehensive training on machine operation and maintenance for personnel can greatly impact overall efficiency.

The following table summarizes key factors affecting milling efficiency:

| Factor | Impact on Yield |

|---|---|

| Moisture Content | Improper levels can lead to excess breakage |

| Machine Settings | Optimal adjustments minimize loss |

| Quality of Rice | Higher quality generally leads to higher yields |

| Operator Skill Level | Directly influences efficiency and quality outcomes |

The Impact of Technology on Rice Quality and Processing Speed

Modern advancements in technology have redefined the landscape of rice milling, leading to significant improvements in both quality and efficiency. The integration of sophisticated milling machines has transformed traditional processes, allowing for better extraction rates and polishing effects. With features like automatic adjustments for various rice types and moisture content, these machines ensure that the end product meets higher safety and quality standards. Additionally, precise milling techniques minimize broken kernels, thus improving overall yield, which is crucial for both producers and consumers in an ever-competitive market.

Furthermore, technology has expedited the processing timeline, reducing the turnaround between harvest and market availability. Automated systems allow for continuous processing, effectively streamlining workflows. These modern machines not only increase processing speed but also enhance energy efficiency, making operations more sustainable. A glance at the benefits of these machines reveals their critical role in enhancing profitability for rice mills, transforming them into centers of efficiency rather than just processing facilities. Consider the following advantages:

- Faster Processing Times: Reduction in milling time per batch.

- Improved Grain Quality: Enhanced bran removal and polishing.

- Labor Savings: Minimized workforce requirements through automation.

- Higher Profit Margins: Better yield translates to increased revenue.

Investing in Innovation: Choosing the Right Milling Equipment for Your Needs

When it comes to optimizing rice production, selecting the right milling equipment is paramount. Innovatively designed rice milling machines provide enhanced processing efficiency and superior final product quality. Some of the key features to consider include:

- Capacity: Ensure the machine can handle your processing volume, whether for small-scale or industrial use.

- Processing Precision: Look for equipment that minimizes broken grains and maximizes yield.

- Energy Efficiency: Choose machines that consume less power, contributing to cost savings and sustainability.

- Maintenance: Assess the ease of maintenance and availability of spare parts to reduce downtime.

By carefully evaluating these aspects, you can make informed decisions that align with your operational goals. Additionally, consider the technological advancements that come with modern milling equipment. Many of the latest machines feature:

| Feature | Benefit |

|---|---|

| Automated Sensors | Enhance accuracy in grain sorting and reduce manual labor. |

| Integrated Drying Systems | Ensure optimal moisture content, improving storage life. |

| Smart Technology | Enable real-time monitoring and diagnostics for optimal performance. |

These innovations not only streamline rice milling processes but also contribute to higher quality outcomes and improved profitability. By investing in the right rice milling machines, businesses can achieve greater operational efficiency and elevate their competitive edge in the market.

Future Outlook

In the bustling world of agriculture, where every grain counts, rice milling machines stand as unsung heroes, transforming harvested paddy into the staple that nourishes millions. As we have explored, these machines not only enhance productivity but also play a pivotal role in ensuring quality and sustainability within the rice supply chain. By embracing technological advancements and innovations in milling processes, we unlock newfound efficiencies that fuel both local economies and global food security.

As we look to the future, it is clear that the journey of rice from field to fork is a complex interplay of tradition, innovation, and necessity. The essential role of rice milling machines cannot be overstated; they are the bridge between harvest and consumption, empowering farmers and consumers alike. By investing in and optimizing these technologies, we pave the way for a more efficient, sustainable, and resilient agricultural landscape.

In this era of rapid change, let us remain committed to unlocking the potential of rice milling—ensuring that every kernel tells a story of progress, diligence, and the relentless pursuit of efficiency. As we cultivate innovation, we also cultivate hope for a world where every meal is a testament to the power of transformation.