In the heart of countless kitchens around the world, rice stands as a staple ingredient, its humble presence a testament to its versatility and nourishment. Yet, the journey from paddy to perfectly polished grain is often overlooked—the transformation that requires not only art, but also an intricate understanding of science. Enter the rice milling machine, a marvel of engineering that bridges traditional practices with modern technology. This article delves into the fascinating world of rice milling, exploring how these machines not only refine grains but also preserve the essence of their origin. Through the lens of innovation and craftsmanship, we will unravel the complexities of rice milling, shedding light on the methods and machinery that ensure this essential food staple reaches our tables in its best form. Join us as we embark on a journey through the grains, where every kernel tells a story of transformation and expertise.

Exploring the Mechanics Behind Rice Milling Machines

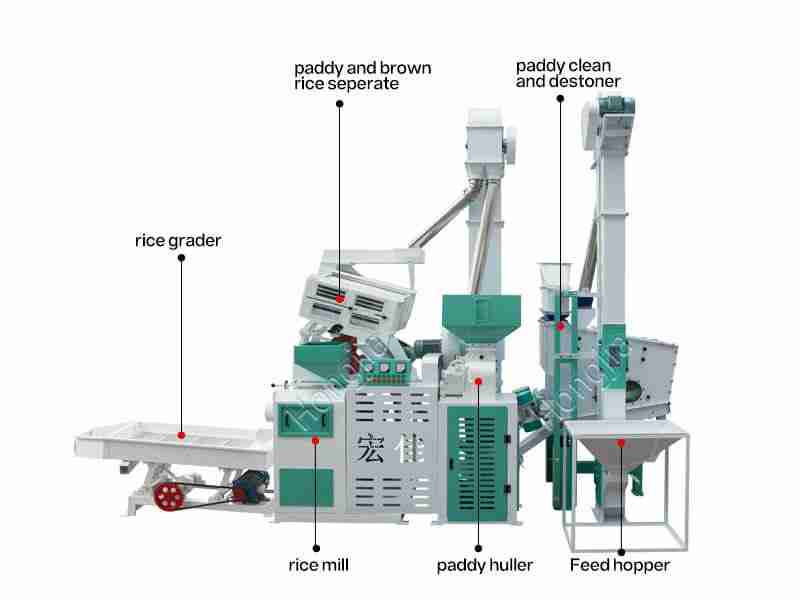

In the heart of rice production lies the intricate machinery that transforms harvested grains into the staple food we cherish. Rice milling machines operate through a series of finely-tuned processes that not only enhance the grain’s quality but also ensure efficiency in production. At the core of these machines are several components, each playing a crucial role in the milling process:

- Dehusking Unit: This component removes the outer husk from the rice grain, preparing it for further processing.

- Milling Chamber: Here, the dehusked rice is transformed into white rice through grinding and friction.

- Separator: This machine separates the rice from the by-products, such as bran and broken grains, ensuring a clean final product.

- Polisher: The final step adds gloss to the rice grains, enhancing its appeal and preparing it for packaging.

Understanding the dynamics of a rice milling machine reveals its multifaceted approach to grain transformation. Let’s take a closer look at a few notable aspects of the process:

| Process Step | Function | Outcome |

|---|---|---|

| Husking | Removal of the outer husk | Brown rice formation |

| Milling | Grinding of grains | White rice production |

| Polishing | Enhancing appearance | Shiny, polished rice |

Each of these steps is engineered to optimize the quality and yield of rice while minimizing waste. By harnessing advanced technology and fine-tuning each phase of milling, these machines not only produce market-ready rice but also contribute to sustainability in agricultural practices. The art of milling rice, therefore, stands as a testament to the beautiful intersection of tradition and innovation in food processing.

Innovative Technologies Revolutionizing Grain Processing

In the ever-evolving field of agriculture, advanced technologies are redefining the grain processing landscape. Today’s rice milling machines integrate cutting-edge innovations such as AI-driven analytics and automated quality control systems. These machines leverage sophisticated algorithms to monitor the milling process in real-time, ensuring optimal outcomes in terms of both efficiency and yield. This results not only in superior rice quality but also in diminished waste and associated costs, making the production cycle more sustainable. A few critical technological advancements include:

- Smart Sensors: These devices enhance precision by monitoring moisture levels and grain temperatures, adapting to conditions instantly.

- IoT Integration: Connected machines allow farmers to access data remotely, optimizing operational decisions and resource management.

- Energy-Efficient Designs: New milling systems consume less power without compromising productivity, aligning with global energy conservation goals.

Moreover, the introduction of robotic milling technologies is transforming traditional methods, decreasing the labor force needed while increasing safety and productivity. Modern machines not only handle the physical aspects of milling but also offer user-friendly interfaces for operators. As the industry pushes forward, emerging trends also emphasize the necessity of sustainable practices, with a focus on minimizing environmental impact. The integration of such revolutionary technologies can be summarized in the table below:

| Technology | Benefit |

|---|---|

| AI-Driven Analytics | Improved efficiency and higher yields |

| Smart Sensors | Enhanced precision and real-time monitoring |

| IoT Connectivity | Remote access to operational data |

| Energy-Efficient Machines | Lower energy consumption and costs |

Optimizing Efficiency in Rice Milling Operations

In the quest to enhance productivity within rice milling operations, the integration of advanced technologies and strategic practices is paramount. Automation in milling machines significantly reduces manual labor, improving both speed and quality. Additionally, implementing real-time monitoring systems allows operators to track efficiency metrics, enabling timely interventions when discrepancies occur. Furthermore, training personnel on advanced machinery ensures that they are equipped with the necessary skills to operate and troubleshoot machines, promoting a culture of continuous improvement.

Another effective approach to optimizing efficiency involves maintaining and upgrading equipment regularly. A predictable maintenance schedule not only extends the lifespan of machinery but also minimizes unexpected downtime. It is equally important to analyze the workflow layout within the milling facility. By arranging machinery in a logical sequence, unnecessary handling can be avoided, thus diminishing waste and accelerating processing times. The following table illustrates some key factors contributing to operational efficiency:

| Efficiency Factor | Description |

|---|---|

| Automation | Reduces manual labor and speeds up processes. |

| Real-Time Monitoring | Allows for immediate adjustments based on performance metrics. |

| Regular Maintenance | Prevents breakdowns and prolongs equipment lifespan. |

| Improved Layout | Enhances workflow by minimizing unnecessary movement. |

Sustainability Practices in Modern Rice Milling Techniques

In the quest for a more sustainable future, modern rice milling techniques have undergone significant transformations that prioritize environmental responsibility alongside efficiency. By adopting energy-efficient machinery and waste reduction processes, rice mills are minimizing their carbon footprint while maximizing productivity. Key advancements include:

- Solar-Powered Milling Equipment: Integrating solar panels to power milling operations reduces reliance on fossil fuels.

- Water Recycling Systems: Implementing systems that treat and reuse water minimizes waste and conserves this precious resource.

- Biomass Utilization: Scooping up the by-products from the milling process to produce bioenergy reduces overall waste.

Furthermore, the implementation of precision milling technologies ensures that every grain is processed with minimal loss. This not only preserves the quality of the rice but also aligns with the principles of circular economy by converting waste into resources. Consider the following efficiency metrics:

| Practices | Impact |

|---|---|

| Use of Parboiling | Enhances nutritional value and reduces waste. |

| Zero-Waste Policies | Maximizes resource utilization and minimizes landfill impact. |

Wrapping Up

As we conclude our exploration of the intricate world of rice milling machines, it becomes clear that this blend of art and science plays a pivotal role in the journey of rice from field to table. These machines, embodying technological advancements and skilled engineering, not only enhance the quality and efficiency of rice production but also preserve the essential flavors, textures, and nutrients that define this staple food.

The transformation of grains is much more than a mechanical process; it is a symphony of innovation, tradition, and sustainability, echoing the rhythm of cultures intertwined with rice. As we look towards the future, the ongoing evolution of milling technologies promises to meet the growing demands of a diverse global population, while also prioritizing eco-friendly practices.

In appreciating the craftsmanship behind rice milling machines, we celebrate the continuity of an age-old tradition, reimagined through modern ingenuity. Whether you’re a farmer, a miller, or simply an aficionado of this cherished grain, understanding the nuances of rice milling invites us to respect the origins of what we consume and to ponder the journeys our food undertakes before gracing our plates. In the grand tapestry of agricultural innovation, rice milling stands testament to the beautiful intersection of nature and technology, inviting us all to partake in the marvel of transformation.