Harvest to Hurdles: The Art of Paddy Processing Explained

As the golden hues of rice fields sway gently under the sun’s warm embrace, the journey from paddy to plate is about to unfold—a journey rich in tradition, precision, and passion. Paddy processing is not merely a series of mechanical steps; it is an intricate dance between nature and nurture, where grains are transformed into essential sustenance for millions. In this article, we delve into the art of paddy processing, exploring the meticulous stages that elevate this humble crop into its revered status. From the initial harvest to the myriad hurdles faced along the way, we will uncover the craftsmanship behind each grain, revealing the science, the skill, and the stories that make rice one of the world’s most important staple foods. Join us as we explore the delicate balance between heritage and innovation, and appreciate the complex process that bridges rural fields with urban kitchens.

Understanding the Significance of Choosing the Right Paddy Variety

Choosing the appropriate variety of paddy is a critical decision that can significantly influence agricultural productivity and the quality of the harvest. Factors such as climate adaptability, growth duration, and resistance to pests and diseases play pivotal roles in this choice. For small-scale farmers, selecting a variety that align with their specific environmental conditions can optimize yield and reduce losses. Consequently, understanding the traits of different paddy varieties allows farmers to make informed decisions that enhance their agricultural practices and profitability.

Furthermore, the right paddy variety not only contributes to higher yields but also affects the end market value of the produce. Certain varieties are preferred for their flavor, texture, and cooking qualities, which can appeal to different segments of consumers. This market demand can result in premium pricing for farmers who invest in cultivating high-quality or specialty rice types. In the table below, we summarize some commonly grown paddy varieties along with their key characteristics:

| Paddy Variety | Growth Duration | Market Appeal | Resistance |

|---|---|---|---|

| Basmati | 120-150 days | High demand for aroma and taste | Moderate disease resistance |

| Sona Masuri | 110-125 days | Popular in South India | High pest resistance |

| IR64 | 90-110 days | Widely grown staple variety | Strong against blast disease |

| Jasmine | 115-140 days | Known for its fragrant profile | Moderate to low pest resistance |

Essential Techniques for Efficient Harvesting and Initial Processing

To maximize yield and quality during paddy harvesting, timing is crucial. One of the essential techniques is to assess the moisture content of the grains, which should ideally be below 20%. Harvesting too early may result in grain spoilage, while waiting too long can lead to shattering. Employing proper harvesting equipment, such as sickles or modern combine harvesters, can significantly enhance efficiency. Furthermore, to prevent losses during this critical phase, farmers can implement the following practices:

- Utilize sharp tools to reduce grain damage.

- Harvest in dry weather to minimize moisture retention.

- Work in small plots to ensure better management and control.

- Collect fallen grains to prevent wastage.

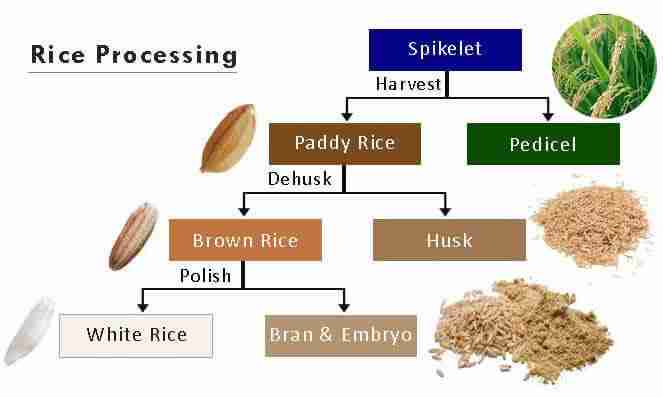

Once harvested, initial processing focuses on drying and de-husking, which are vital in preserving the harvested grains. Efficient drying techniques, such as using sun-drying or mechanical dryers, are crucial to achieve the recommended moisture content of around 14% for safe storage. Following drying, the de-husking process removes the outer layers of the paddy, ensuring the grain is ready for market or further processing. Understanding equipment options like huskers and de-huskers can streamline this process. The following table outlines popular methods of initial processing:

| Processing Method | Advantages | Common Equipment |

|---|---|---|

| Sun-Drying | Cost-effective, utilizes natural resources | Drying mats |

| Mechanical Drying | Faster, controls moisture levels effectively | Grain dryers |

| Traditional De-husking | Low investment, suitable for small scales | Sickle, mortar |

| Modern De-husking | High efficiency, suitable for large batches | De-huskers |

Navigating the Challenges of Drying and Storage in Paddy Processing

One of the most critical phases in paddy processing lies in the drying and storage stages, where careful attention is essential to maintain grain quality and prevent losses. Proper drying not only reduces the moisture content of paddy but also helps in preventing fungal infections and pest infestations. However, achieving optimal drying can be challenging due to environmental factors such as humidity and temperature. Two common drying methods include:

- Sun Drying: Utilizes natural sunlight and is cost-effective, but it’s highly dependent on weather conditions.

- Mechanical Drying: Offers more control over temperature and humidity, but requires investment and energy consumption.

Following the drying phase, the importance of appropriate storage cannot be overstated. Improper storage can lead to a decline in grain quality, resulting from moisture absorption or pest activity. A well-ventilated, cool, and dry storage environment minimizes these risks and prolongs shelf life. To better manage this stage, key storage considerations include:

| Storage Method | Benefits | Drawbacks |

|---|---|---|

| Jute Bags | Breathable and inexpensive | Susceptible to moisture and bugs |

| Steel Silos | Durable and pest-resistant | Higher initial investment |

By recognizing the delicate balance required for effective drying and storage, paddy processors can enhance yield quality, safeguard against losses, and maximize profitability in their operations.

Maximizing Quality: Best Practices for Milling and Packaging Rice Products

Milling rice products requires precision and attention to detail to ensure the highest quality outcomes. Employing modern technology can significantly improve the milling process, which typically involves several stages, including cleaning, hulling, and polishing. To enhance the quality of the final product, consider implementing the following best practices:

- Invest in Quality Machinery: Utilizing state-of-the-art milling equipment minimizes grain breakage and maximizes yield.

- Regular Maintenance: Routine checks and maintenance of machinery help in preventing functional failures and ensuring optimal performance.

- Quality Control Checks: Perform frequent quality inspections at each stage of milling to identify impurities or defects early on.

Packaging plays an equally crucial role in maintaining the quality of rice products post-milling. A good packaging strategy can protect products from moisture, pests, and other environmental factors that can degrade quality. Consider these essential packaging practices:

- Use High-Quality Materials: Choose packaging materials that offer an airtight seal and resistance to moisture.

- Adopt Innovative Designs: Think outside the box with packaging designs that enhance visibility and branding while ensuring functionality.

- Sustainability Matters: Prioritize eco-friendly packaging solutions that appeal to environmentally-conscious consumers.

| Best Practice | Description |

|---|---|

| State-of-the-art Machinery | Efficient milling with minimal grain loss. |

| Regular Quality Checks | Prevent defects by inspecting each processing stage. |

| Eco-Friendly Packaging | Sustainable materials to enhance brand image. |

Closing Remarks

As we draw the curtain on our exploration of “Harvest to Hurdles: The Art of Paddy Processing,” it becomes clear that this intricate journey is about more than just transforming a humble grain into a staple food. It embodies centuries of tradition, innovative techniques, and the harmonious relationship between man and nature. Each stage of processing is a testament to the knowledge passed down through generations, unveiling the dedication of farmers and processors who work tirelessly to ensure that every grain reaches our tables in its finest form.

Understanding the multifaceted art of paddy processing not only enriches our appreciation for this essential crop but also highlights the challenges and innovations that shape its future. As we navigate a world increasingly focused on sustainability and quality, the methods we adopt in paddy processing will play a pivotal role in securing food systems for generations to come.

So, the next time you savor a bowl of rice, take a moment to reflect on the journey it has made—from the lush fields where it was nurtured to the complex processes that refined it. the art of paddy processing is a celebration of resilience, creativity, and the enduring connection we share with the foods that nourish us.