In the bustling heart of agriculture, rice stands as a staple food for billions around the globe, weaving its way through cultures and cuisines. However, the journey from paddy field to kitchen is laden with challenges, particularly in the milling process, where efficiency and quality can often be at odds. Enter the mini rice milling machine—a compact yet powerful innovation that promises to revolutionize the rice milling landscape. By unlocking new levels of efficiency, these machines not only streamline production but also empower smallholders and rural entrepreneurs to thrive. This article delves into the transformative impact of mini rice milling machines, exploring how they are redefining processes, enhancing productivity, and ultimately securing a more sustainable future for rice production. Join us as we uncover the pivotal role these machines play in unlocking a world of potential within the grain industry.

Exploring the Mechanics Behind Mini Rice Milling Machines

Mini rice milling machines have revolutionized the traditional approach to rice processing, transforming it into a more efficient and streamlined process. These compact powerhouses utilize an integrated system of huskers, shellers, and grinders to ensure that rice is milled to perfection. The key components work in harmony to remove the inedible outer husk and polished the grains, while minimizing waste and maximizing yield. The portability of these machines allows them to be positioned near rice fields, enabling immediate processing that locks in freshness and flavor.

One of the standout features of mini rice milling machines is their energy efficiency, which stems from advanced engineering and technology. Many models are designed with low energy consumption in mind, utilizing electric motors that require less power while maintaining high efficiency. Additionally, users can benefit from:

- Adjustable settings for different rice varieties, ensuring optimal milling performance.

- Durability using robust materials that withstand the rigors of continuous operation.

- Ease of maintenance with user-friendly designs that reduce downtime.

| Feature | Benefit |

|---|---|

| Compact Design | Space-saving and portable for easy transport |

| Multi-functionality | Processes multiple rice types with different settings |

| Energy Efficient | Reduces operational costs and promotes sustainability |

Streamlining Production: Benefits of Investing in Mini Mills

Investing in mini mills offers a multitude of advantages that significantly enhance production efficiency. These compact machines exemplify the balance between size and output, enabling small to medium-sized operations to achieve high productivity without the massive footprint of traditional milling setups. By adopting mini rice milling machines, businesses can reduce operational costs, which includes lower energy consumption and minimized labor expenses, ultimately leading to increased profitability.

In addition, flexibility and adaptability are key features of mini mills. They are designed to accommodate diverse processing needs, making it easier for producers to switch between different rice varieties or milling processes with minimal downtime. The compact nature of these machines facilitates ease of maintenance, ensuring that businesses can keep their operations running seamlessly. Other notable benefits include:

- Lower capital investment: Less upfront capital required compared to larger plants.

- Quick setup: Faster installation times leading to quicker returns on investment.

- Improved product quality: Advanced technology that ensures better milling precision and grain quality.

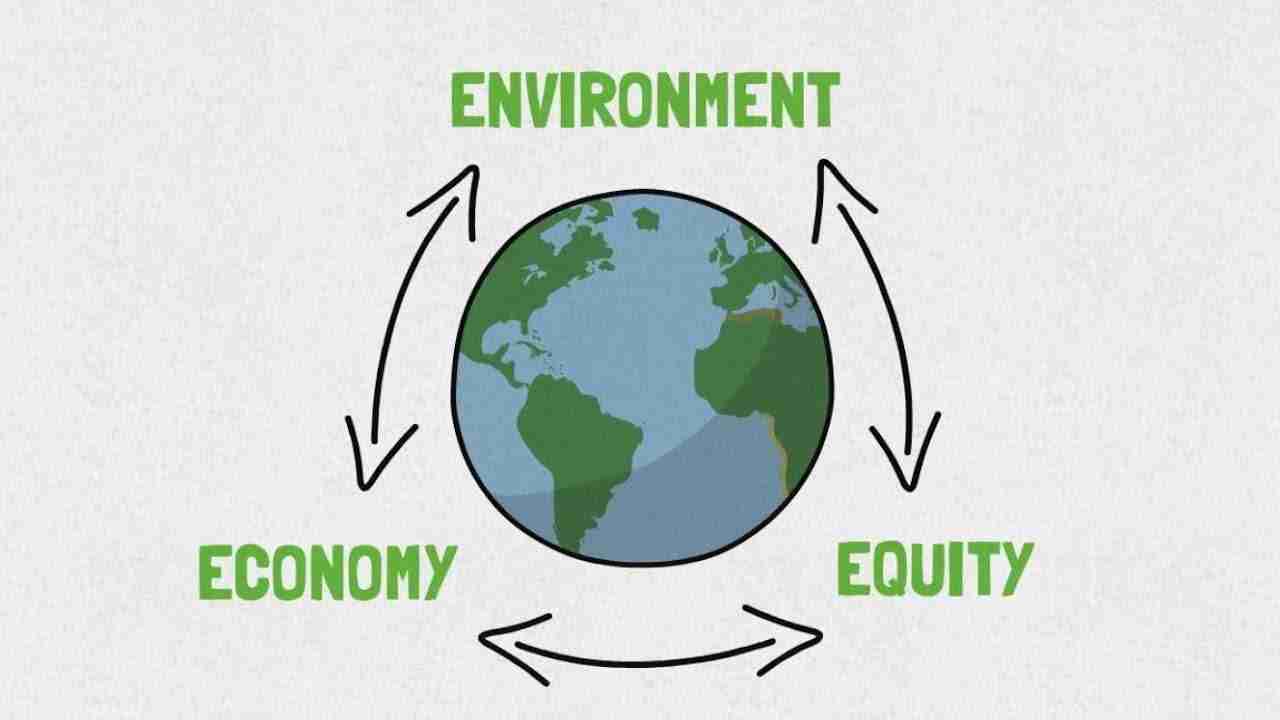

Sustainability in Rice Processing: Eco-Friendly Innovations

In the quest for eco-friendly rice processing, mini rice milling machines have emerged as a beacon of sustainable innovation. By leveraging advanced technology, these compact systems minimize energy consumption while maximizing output and efficiency. Traditional milling methods often generate excessive waste and CO2 emissions; however, with the introduction of small-scale milling, farmers can enjoy a range of environmental benefits including:

- Reduced Energy Use: Mini machines often operate on lower power, allowing farmers to reduce their carbon footprint.

- Less Waste Generation: Innovative designs ensure that grain husks and other byproducts are minimized, allowing for repurposing.

- Local Processing: By milling rice closer to the source, transportation emissions are significantly decreased.

Moreover, these modern milling machines are designed with sustainability in mind. For instance, the integration of renewable energy sources, such as solar power, is becoming increasingly feasible. This not only supports a self-sustaining processing cycle but also provides the added benefit of lower operating costs. A comparison of environmental impacts between traditional and mini rice milling systems illustrates the clear advantages of switching to more sustainable practices:

| Aspect | Traditional Milling | Mini Rice Milling |

|---|---|---|

| Energy Consumption | High | Low |

| Waste Generation | High | Minimal |

| Transportation Emissions | Significant | Reduced |

Maximizing Profitability: Best Practices for Small Scale Millers

To elevate the profitability of small-scale milling operations, millers must adopt strategies that blend efficiency and quality. One of the most effective approaches is to invest in mini rice milling machines. These compact units not only reduce operational costs but also streamline the milling process, allowing millers to process larger quantities of rice with less labor and time. With modern technology, these machines are designed to deliver consistent quality while minimizing grain breakage, enabling millers to maximize their yield and satisfaction among customers.

Furthermore, small millers can enhance their profitability by implementing best practices in maintenance and operation of their machinery. Regular maintenance helps to prevent unexpected breakdowns, ensuring that production schedules remain uninterrupted. Some key practices include:

- Daily checks: Ensure that all parts are functioning correctly to maintain efficiency.

- Training staff: Invest in training programs for operators to enhance their skills in handling machinery.

- Inventory management: Monitor spare parts and raw materials to avoid production delays.

By fusing technology with these operational insights, small-scale millers can significantly improve their profit margins in a competitive market.

Final Thoughts

the advent of mini rice milling machines represents a significant step forward in the quest for efficiency in rice production and processing. These compact powerhouses not only streamline operations but also empower small-scale farmers and entrepreneurs to transform their livelihoods. As we embrace innovation in agricultural technology, it is essential to recognize the profound impact these machines have on food security, sustainability, and local economies. By unlocking the potential of these tools, we pave the way for a future where rice milling is not just a process, but a catalyst for growth and development in communities around the world. As we move forward, let us continue to explore and invest in solutions that enhance productivity, reduce waste, and foster a more resilient agricultural landscape.