Launching a 2-Ton Rice Mill Plant: A Guide to Success

In the heart of agrarian economies, rice stands as a staple food and a symbol of sustenance, feeding billions across the globe. As demand for quality rice surges, the opportunity to transform this essential crop into a thriving business venture has never been greater. Enter the 2-ton rice mill plant—a pivotal element in the rice production chain that promises not only profit potential but also the chance to contribute to food security and local economies. However, stepping into this entrepreneurial landscape requires careful navigation. From choosing the right machinery to understanding market dynamics, establishing a successful rice mill plant involves a multitude of factors that can determine its trajectory. In this comprehensive guide, we’ll explore the key steps to launching a 2-ton rice mill plant, offering practical insights and industry best practices to ensure your venture flourishes against the backdrop of a bustling agricultural market. Whether you’re a seasoned entrepreneur or a newcomer to the field, join us on the journey to uncover the nuances of this rewarding endeavor.

Understanding Market Demand and Feasibility for a rice mill plant

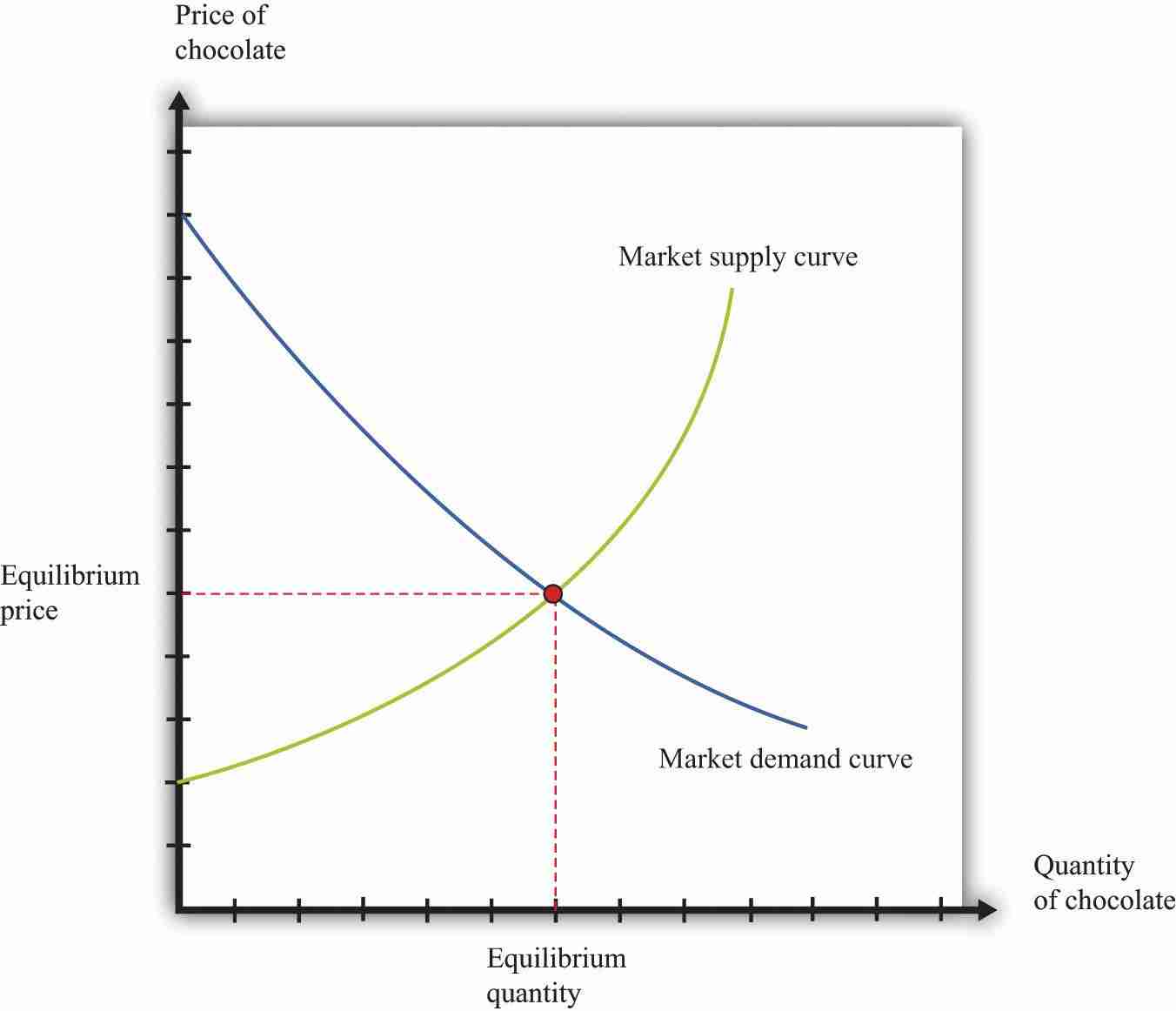

In the journey of launching a rice mill plant, a thorough grasp of market demand and feasibility is fundamental to ensuring sustainability and profitability. Understanding the local agricultural landscape, consumer preferences, and market trends can help mill owners position themselves effectively. Consider the following factors when assessing market demand:

- Population Growth: An increase in population often leads to heightened rice consumption.

- Consumption Trends: Identify whether consumers prefer varieties like jasmine, basmati, or brown rice.

- Regional Supply: Evaluate the proximity of rice farms to potential buyers to minimize transportation costs.

- Packaging Preferences: Understand how consumers perceive packaged vs. bulk rice products.

Feasibility studies play a pivotal role in determining the viability of the rice mill project. By analyzing operational costs, potential revenue streams, and investment requirements, stakeholders can make informed decisions. Key components of a comprehensive feasibility study may include:

| Component | Description |

|---|---|

| Market Analysis | Evaluating competition, pricing strategies, and market saturation. |

| Site Selection | Choosing a location that reduces logistics costs and maximizes accessibility to raw materials. |

| Financial Projections | Estimating operational costs, return on investment, and break-even analysis. |

| Regulatory Considerations | Understanding local laws and environmental regulations affecting rice milling operations. |

Essential Equipment and Technology Choices for Optimal Efficiency

When it comes to setting up a rice mill plant, selecting the right equipment and technology is crucial for maximizing production and minimizing downtime. Essential machinery includes rice huskers, whitener machines, and polishers. Each piece of equipment should be chosen based on its energy efficiency and output capacity to align with the 2-ton requirement. Automation technology can also play a significant role; incorporating sensor-based controls and real-time monitoring systems can enhance operational efficiency, ultimately leading to higher profits.

Moreover, supporting technology such as cleaning machines and storage solutions should not be overlooked. Proper grain handling systems ensure the integrity of the rice, while effective packaging solutions can streamline distribution processes. Below is a table summarizing key equipment features:

| Equipment Type | Key Features | Benefits |

|---|---|---|

| Rice Huskers | High-speed operation, low energy consumption | Increases throughput, reduces operational costs |

| Whitener Machines | Adjustable settings for different grain types | Enhances grain quality, minimizes waste |

| Storage Solutions | Climate-controlled, pest-resistant | Extends shelf life, prevents spoilage |

Strategic Planning for Site Location and Infrastructure Development

Choosing the right site for a rice mill plant is crucial for maximizing operational efficiency and ensuring a sustainable business model. Key factors to consider include access to raw materials, proximity to markets, and transportation infrastructure. A well-situated facility can not only reduce logistical costs but also enhance responsiveness to customer needs. Considerations for site location should include:

- Proximity to Rice Producers: Being close to suppliers reduces transportation costs and ensures fresh procurement.

- Access to Major Roads: Convenient access to highways and transportation hubs can improve delivery times and expand market reach.

- Availability of Utilities: Ensure that the site has reliable water, power, and waste disposal systems to support operations.

- Land and Zoning Regulations: Confirm that the site complies with local zoning laws, and that the land is suitable for industrial development.

Infrastructure development plays a pivotal role in supporting the operational functionality of the rice mill. Consider implementing a layout that promotes efficiency and safety, accommodating both production processes and employee welfare. An effective plan may include the following essential infrastructure components:

| Component | Description |

|---|---|

| Milling Equipment | Sophisticated machinery to process rice efficiently, enhancing product quality. |

| Storage Facilities | Proper storage units to maintain grain quality and minimize spoilage. |

| Waste Management System | A system to handle by-products and waste efficiently, adhering to environmental regulations. |

| Worker Amenities | Facilities that provide comfort for staff, including break rooms and rest areas. |

Building a Sustainable Supply Chain for Raw Materials and Distribution

Establishing a sustainable supply chain for raw materials and distribution is crucial for the long-term viability of a rice mill plant. To ensure a constant and responsible supply of paddy, consider forging partnerships with local farmers who practice sustainable agriculture. This collaboration not only supports the local economy but also ensures that your mill has a reliable source of quality input. Focus on implementing practices that prioritize environmental health, social responsibility, and economic viability, creating a win-win situation for all stakeholders involved. Incorporating technology, such as blockchain, can also enhance transparency in the supply chain and foster trust between producers and suppliers.

Distribution is equally important, as it dictates how efficiently your finished product reaches consumers. Here are key strategies to enhance your distribution sustainability:

- Optimize Logistics: Use data analytics to streamline routes, reducing fuel consumption and transportation costs.

- Engage Local Distributors: Collaborating with local distributors can cut down on transportation emissions while supporting regional economies.

- Implement Eco-Friendly Packaging: Choose biodegradable or recyclable materials to minimize waste and appeal to environmentally conscious consumers.

Create a table to keep track of partnerships and distribution metrics:

| Partner Type | Name | Location | Responsibility |

|---|---|---|---|

| Farmers | Green Fields Co. | Near City A | Supplies Organic Paddy |

| Distributors | Fresh Grain Ltd. | City B | Local Distribution |

| Packaging Suppliers | EcoWraps | City C | Biodegradable Packaging |

To Wrap It Up

Conclusion: Sowing the Seeds of Success

As you embark on the journey of launching a 2-ton rice mill plant, remember that success is not a mere destination but a multifaceted process that requires diligence, strategy, and adaptability. By understanding the nuances of the rice milling industry and aligning your operations with local market demands, you set the stage for not only profitability but also sustainability.

The key to thriving in this venture lies in meticulous planning, informed decision-making, and the ability to embrace challenges as opportunities for growth. Engage with your community, foster relationships with suppliers, and stay abreast of technological advancements to keep your plant competitive in an ever-evolving market.

the fruits of your labor will be reflected not just in the grains you process but in the positive impact you create within your community. Your rice mill will stand as a testament to innovation, a hub of economic activity, and a source of nourishment for many. May your venture yield bountiful rewards and inspire others in their agricultural pursuits. Best of luck on this exciting path ahead!