Harvest to Home: The Journey Through a Paddy Processing Plant

In the quiet embrace of rural landscapes, where golden fields of rice sway gently under the sun’s caress, an intricate journey unfolds—one that transforms the bounty of harvest into the staple grains that grace our tables. Welcome to the world of paddy processing, a vital yet often overlooked link in our food supply chain. As sunlight bathes the fields and whispers of wind accompany the rhythmic rustle of the crops, a meticulous process begins, illuminating the journey from harvest to home.

Step inside a paddy processing plant, where science and tradition converge to cultivate the fruits of labor into edible perfection. From the moment the rice is gathered, through stages of drying, milling, and packaging, each phase is a testament to the hard work and innovation driving the agricultural industry. This article invites you to explore the dynamic operations behind the scenes, revealing the artistry involved in shaping raw grains into the polished grains we know and cherish. Join us as we trace the intricate path of rice, uncovering the stories woven into every grain along the way.

The Path of Grain: Understanding the Journey from Paddy to Rice

The journey of rice begins in lush, green fields where paddy is grown under the watchful eye of the sun. Once the crops reach maturity, typically between 90 to 180 days depending on the variety, the harvest begins. Farmers use modern machinery alongside traditional methods to cut the tall stalks, ensuring minimal damage and maximum yield. After harvesting, the paddy, still encased in its protective husk, undergoes a series of processing steps to transform it into the white grains familiar in households around the world. The journey truly illustrates the connection between nature and nutrition.

At the processing plant, the journey takes on a more mechanized approach. The paddy enters the facility where it is cleaned, removing any impurities such as dirt, stones, and leftover straw. Following this, it proceeds to drying chambers, ensuring the moisture content is just right before moving on to milling. Key steps in the milling process include:

- Husk Removal: The outermost husk is mechanically stripped away, leaving the brown rice.

- Bran Separation: The brown rice is polished to remove the bran layer, resulting in white rice.

- Grading: The rice is sorted based on size, color, and quality before packaging.

This careful processing enhances quality while maintaining essential nutrients, showcasing the precision and innovation involved in the journey from field to table.

Inside the Machinery: Innovations Driving Efficiency in Paddy Processing

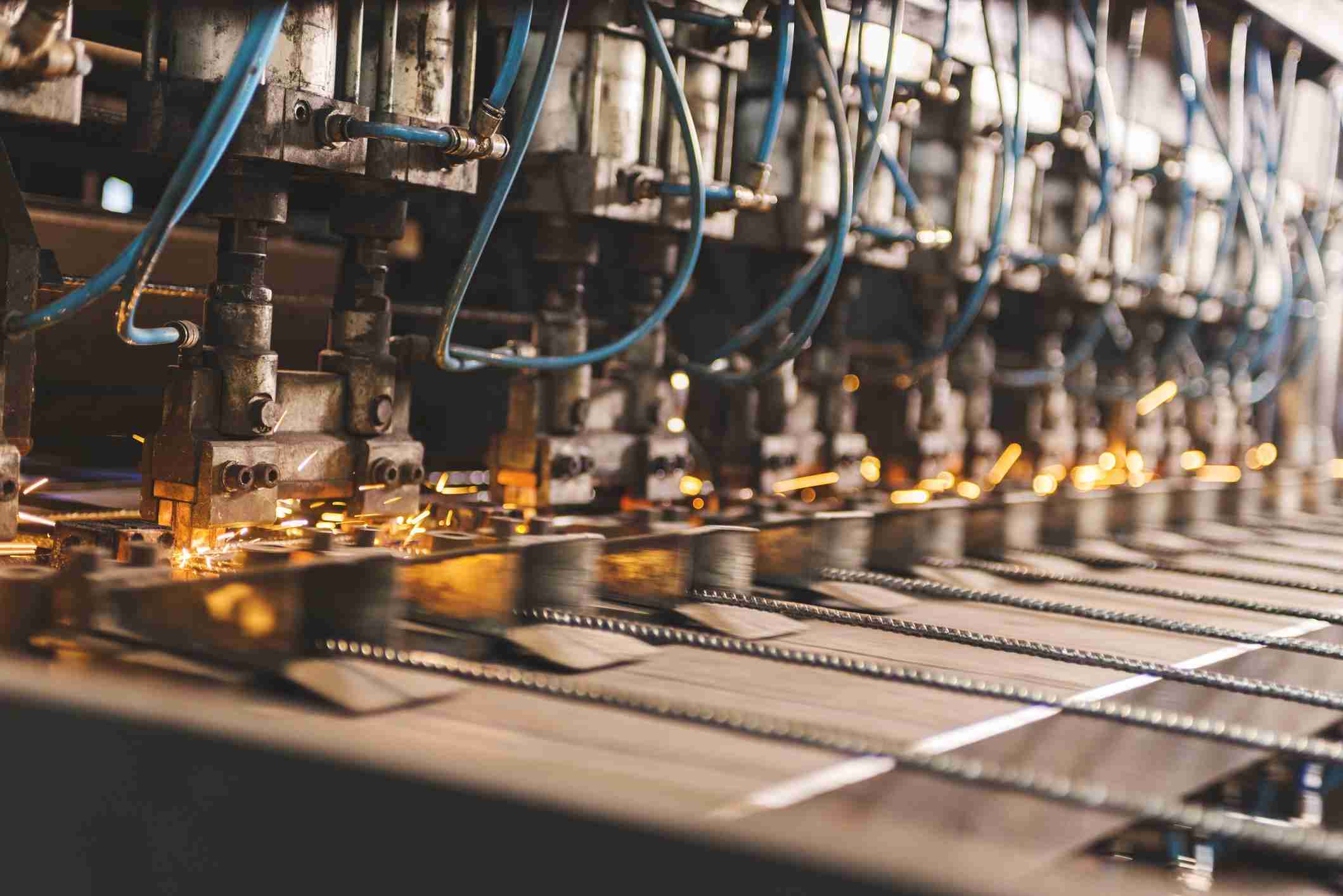

The heart of paddy processing plants lies in their innovative machinery, engineered to transform freshly harvested rice into a market-ready product. These machines not only enhance productivity but also maintain the quality and flavor of the grain. Some of the standout innovations include:

- Modern Combine Harvesters: Equipped with GPS technology and advanced sensors, these harvesters maximize yield by monitoring crop health and optimizing harvesting conditions.

- High-Efficiency Grain Dryers: Utilizing renewable energy sources, these dryers reduce energy costs while ensuring that moisture levels are consistent, critical for preventing spoilage.

- Automated Milling Machines: With precision cutting and minimal grain loss, modern milling systems significantly improve the efficiency of converting paddy to rice.

The processing workflow is meticulously designed to ensure each step is efficient and environmentally friendly. Below is a brief overview of the different stages within a paddy processing plant:

| Processing Stage | Description |

|---|---|

| Cleaning | Removal of impurities such as stones and dust. |

| Husking | Separation of the husk from the grain. |

| Milling | Polishing the brown rice to remove bran layers. |

| Sorting | Using infrared sensors to grade rice based on quality. |

| Packing | Automated systems ensure proper packaging for market distribution. |

Each stage utilizes the latest technology to reduce waste and enhance the quality of the endpoint product. By adopting these innovations, paddy processing plants contribute significantly to sustainable practices while ensuring that rice maintains its essential characteristics as it travels from the field to the consumer’s plate.

Quality Control: Ensuring Excellence at Every Step of the Process

At the heart of paddy processing plants lies a robust framework dedicated to maintaining high standards and achieving exceptional quality in every grain. Every step of the journey—from the moment the paddy is harvested to the point it arrives at your home—demands stringent measures and meticulous attention to detail. To achieve this, a comprehensive quality control system is implemented that includes:

- Visual Inspection: Trained professionals examine raw paddy for impurities and damage.

- Moisture Testing: Moisture levels are checked to ensure optimal drying, preventing spoilage.

- Grain Sorting: High-tech machinery automatically sorts grains by size and quality.

- Sensory Evaluation: Taste testers assess flavor profiles at various stages of packaging.

After these evaluations, a dedicated quality assurance team compiles and analyzes data to highlight potential areas for improvement. This analysis is crucial, acting as a feedback loop ensuring that every batch of rice upholds quality and consistency. Below is a breakdown of the critical quality control stages:

| Quality Control Stage | Description |

|---|---|

| Pre-Processing | Initial checks for foreign materials and moisture content. |

| During Processing | Regular testing for quality during milling and polishing. |

| Post-Processing | Final inspections before packaging and distribution. |

Sustainability Practices: How Processing Plants Are Adapting for a Greener Future

As our planet faces pressing environmental challenges, processing plants are reimagining their operations to incorporate sustainable practices that minimize their ecological footprint. Many facilities are transitioning to renewable energy sources, such as solar and wind power, to significantly reduce their reliance on fossil fuels. This shift not only cuts greenhouse gas emissions but also lowers operational costs in the long term. Moreover, innovative technologies, including energy-efficient machinery and smart sensors, are being integrated into production lines, ensuring that energy waste is minimized while maintaining productivity.

Water conservation is another critical aspect of these sustainability efforts. Processing plants are adopting advanced recycling systems that allow them to capture and reuse water throughout their operations. This practice not only preserves valuable water resources but also reduces the need for wastewater treatment. Furthermore, many facilities are implementing zero-waste initiatives, striving to divert excess byproducts from landfills by reintroducing them into the supply chain or converting them into valuable products. These collective efforts underscore a commitment to creating a more sustainable future within the food production industry.

In Summary

As the sun sets over the vast fields, casting a golden hue across the horizon, the journey from harvest to home comes full circle. The paddy processing plant stands as a testament to the intricate dance between nature and technology, where each grain is treated with care and precision, embodying the labor of farmers and the promise of sustenance.

Throughout this exploration, we have uncovered the remarkable processes that transform raw harvests into the staple that graces our tables – a journey filled with tradition, innovation, and resilience. The delicate balance of maintaining quality while scaling production serves as a reminder of the evolving landscape of agriculture and food processing.

As you reflect on the journey these grains undertake, from the lush green paddies to the polished rice in your pantry, consider the human stories entwined with every bite. It is not just about food; it is about connection, community, and the intricate web of life that sustains us all.

So, the next time you sit down for a meal, pause for a moment to appreciate the unseen journey that has brought that food to your plate. Harvest to home is not merely a process; it is a narrative of dedication, stewardship, and an enduring relationship with the land. Let us honor that journey, for in doing so, we honor the very essence of nourishment itself.