In the heart of agricultural innovation, a quiet revolution is reshaping the landscape of rice production: the emergence of automatic rice mills. Gone are the days when labor-intensive, manual processes dominated the grain milling industry. As technology continues to advance, these automated systems are stepping into the spotlight, promising to streamline operations, increase productivity, and enhance the overall quality of rice processing. From smallholder farmers to large-scale producers, the rise of automatic rice mills is unlocking a new level of efficiency, enabling stakeholders to meet the demands of a growing population. This article explores the transformative impact of these machines, delving into their design, functionality, and the myriad benefits they bring to the world of rice milling. Join us as we uncover how embracing automation in this timeless industry is paving the way for a more sustainable and efficient future.

The Evolution of Rice Milling Technology

The transition in rice milling technology has been a fascinating journey, marked by significant advancements that reflect both innovation and necessity. Early rice milling often relied on manual labor and rudimentary tools, including mortar and pestles, which limited efficiency and productivity. As societies evolved, so did their agricultural practices. The introduction of more sophisticated machinery in the mid-20th century revolutionized the industry. Machinery such as the stone mill and the huller significantly increased output, minimizing the amount of time and effort needed to process rice. Though effective, these early machines often had drawbacks, including poor grain quality and high breakage rates.

With the rise of automatic rice mills, the landscape of rice processing has transformed once again. Today’s technology incorporates high-speed machines with enhanced features aimed at maximizing efficiency and quality. Some key improvements include:

- Automated feeding systems that ensure consistent grain flow

- Advanced polishing units that enhance the rice’s appearance without causing damage

- Integrated cleaning systems that remove impurities prior to milling

This modern approach not only boosts output but also enhances the nutritional quality of the rice, catering to a health-conscious market. Below is a comparison table that highlights over the years:

| Technology | Efficiency | Grain Quality | Labor Requirement |

|---|---|---|---|

| Manual | Low | Basic | High |

| Stone Mill | Moderate | Adequate | Medium |

| Automatic Rice Mill | High | Premium | Low |

Key Benefits of Automatic Rice Mills for Farmers and Businesses

In recent years, the agricultural sector has seen a transformative shift with the advent of automatic rice mills. These state-of-the-art machines are revolutionizing the way farmers and businesses process rice, leading to enhanced productivity and reduced labor costs. One of the primary advantages of these mills is their ability to streamline operations. With integrated technology, farmers can perform dual functions—milling and sorting—simultaneously, significantly reducing the time required for processing. This allows for a faster turnaround from harvesting to market, enabling farmers to capitalize on favorable market prices.

Furthermore, automatic rice mills have been designed with energy efficiency in mind, minimizing power consumption while maximizing output. The precision engineering behind these machines ensures a higher yield of quality rice with less grain loss compared to traditional methods. With the ability to customize milling settings, businesses can cater to varying market demands. Notably, these mills are equipped with advanced features that ensure cleaner products and better storage opportunities, reducing spoilage and waste. Below is a comparative view of conventional versus automatic rice milling:

| Feature | Conventional Mills | Automatic Mills |

|---|---|---|

| Milling Speed | Slow | Fast |

| Labor Requirement | High | Low |

| Energy Consumption | High | Low |

| Grain Loss | Higher | Lower |

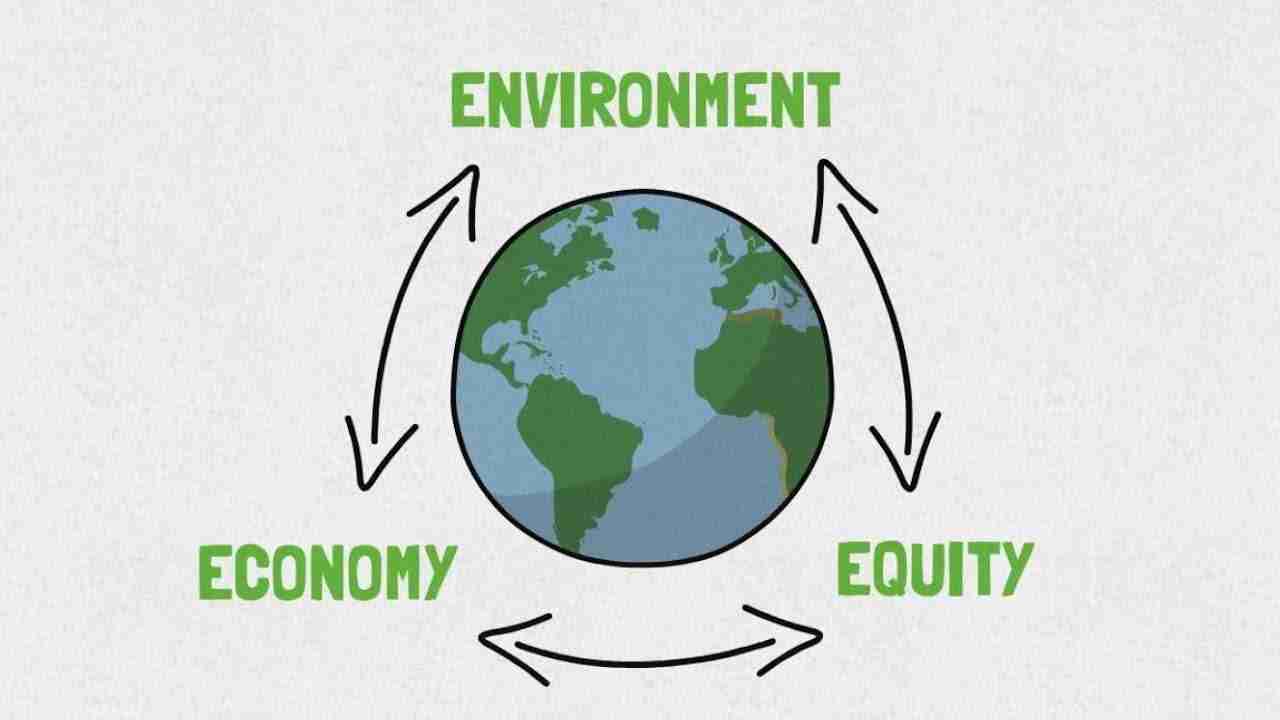

Sustainability and Environmental Impact of Modern Milling Practices

In an era where the quest for sustainability is paramount, modern milling practices are embracing innovative techniques that not only enhance productivity but also lessen their environmental footprint. Automatic rice mills are at the forefront of this transformation, incorporating energy-efficient technologies that reduce electricity consumption while optimizing processing time. By focusing on efficiency, these mills are significantly lowering greenhouse gas emissions, thereby contributing to a healthier ecosystem. Natural waste management is also being prioritized, with by-products being repurposed into animal feed, bioenergy, or even organic fertilizers, thus promoting circular economy principles within the agricultural sector.

The adoption of advanced mill designs and smart automation systems plays a critical role in minimizing water usage and waste generation. Many mills now leverage smart sensors and IoT technology to monitor and control milling processes dynamically, ensuring that resources are utilized judiciously. This leads to not only improved yield but also a reduction in water pollution and soil degradation associated with traditional rice milling methods. The following table summarizes some of the key environmental benefits of modern milling technologies:

| Environmental Benefit | Impact |

|---|---|

| Reduced Energy Consumption | Lower operational costs and carbon footprint |

| Water Efficiency | Minimized water waste and pollution |

| Waste Recycling | Transforming by-products into valuable resources |

| Lower Emissions | Mitigating climate change impacts |

Future Trends and Innovations in Rice Milling Automation

As the rice milling industry evolves, technological advancements are paving the way for innovative solutions that promise to enhance productivity and sustainability. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into rice milling operations is leading to the emergence of smart mills that require minimal human intervention. These automatic systems not only optimize milling processes but also enhance precision in quality control, enabling millers to produce consistent and high-quality rice. The incorporation of advanced sensors and real-time data analytics will allow for predictive maintenance, significantly reducing downtime and operational costs.

Looking ahead, there is a growing trend towards the use of renewable energy sources in rice milling. Innovative designs are being developed to harness energy from biomass, which can power milling operations sustainably. Moreover, automation systems are increasingly focusing on energy efficiency, utilizing advanced algorithms to minimize wastage and streamline processes. The rise of robotic technologies in material handling and packaging also stands to revolutionize the industry, leading to faster production cycles and reducing labor costs. Together, these developments underscore a transformative shift, positioning automated rice mills at the forefront of agricultural innovation.

To Wrap It Up

As we conclude our exploration of the rise of automatic rice mills, it becomes evident that the fusion of technology and tradition is reshaping the landscape of rice production. With their ability to enhance efficiency, reduce labor, and improve product quality, automatic rice mills stand at the forefront of agricultural innovation. As farmers and entrepreneurs embrace these advancements, we witness not only a transformation in processing methods but also a significant impact on local economies and food security.

The journey of rice—from paddy fields to our plates—is becoming more streamlined and environmentally conscious, paving the way for a sustainable future in agriculture. As we move forward, it will be crucial to balance the benefits of mechanization with the values of community and resilience that have long defined rice farming. By harnessing the power of automatic rice mills, we’re not just unlocking efficiency; we’re also unlocking a world of possibilities for generations to come. In this new era of rice production, the grains we harvest today will cultivate a more prosperous tomorrow.