Unveiling the Heart of Grain: The Rice Mill Plant Journey

In the quiet hum of machinery and the rhythmic dance of grains, the journey of rice from field to table unfolds within the walls of a rice mill plant. This intricate process, often overlooked, is a testament to both nature’s bounty and human ingenuity. As we peel back the layers of this essential component of our food system, we delve into the multifaceted world of rice milling—a journey that transforms the raw, unassuming paddy into the gleaming grains we recognize. Join us as we explore the heart of grain, where tradition meets technology, and discover the dedication and craftsmanship that lie at the very core of rice production. Through this exploration, we aim to illuminate the unseen labor and innovation that culminate in each bowl of rice, intricately linking our sustenance to the hands and machines that bring it to life.

Exploring the Rice Milling Process from Grain to Goodness

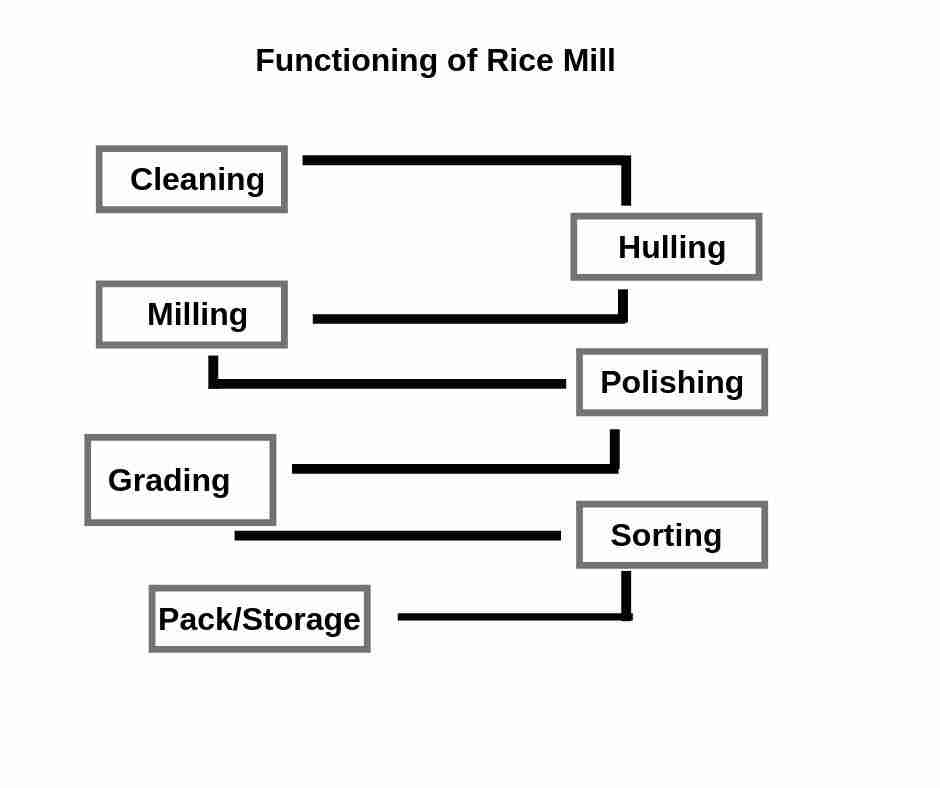

The journey of rice from a simple grain to a staple food involves an intricate milling process that transforms rough paddy into the gleaming white grains we savor. At the heart of this transformation lies the rice mill plant, a hub of activity where technology and tradition converge. The initial step begins with pre-cleaning, where the paddy grains are sorted to remove dirt, stones, and other impurities. Following this, the grains undergo hulling, a method that removes the outer husk, resulting in brown rice. Yet, the real magic happens in the milling stage, which polishes the grains, removing the bran layer to yield white rice while ensuring that the essential nutrients are preserved.

Advancements in milling technology have revolutionized this process, making it more efficient and sustainable. Modern mills utilize multi-stage milling systems and precision machinery that enhance grain separation and reduce waste. Below is a simplified view of the key stages in the rice milling process:

| Stage | Description |

|---|---|

| Pre-Cleaning | Removes impurities such as dirt and stones. |

| Hulling | Eliminates the outer husk to create brown rice. |

| Milling | Polishes the rice and removes bran, leading to white rice. |

| Grading | Sorts the polished rice based on size and quality. |

| Packing | Packages the rice for distribution. |

This meticulous process doesn’t just ensure the quality of the rice; it also enhances its shelf life and marketability. By adapting to new technologies, rice mills are not only preserving the age-old heritage of rice production but also embracing innovation to contribute to food security across the globe. The result is a product that is not just a meal but a symbol of culture, history, and sustenance.

Understanding the Technological Innovations Behind Modern Rice Mills

Modern rice mills have undergone a significant transformation, evolving from traditional methods to sophisticated systems that utilize cutting-edge technology. These innovations streamline the entire milling process, enhancing efficiency and improving yield rates. Today’s rice mills are equipped with automated machinery that reduces the need for manual labor, thus decreasing human error and increasing consistency. Key technologies include:

- Color Sorters: These machines use high-resolution cameras and software to identify and remove broken grains and foreign materials based on color.

- Paddy Separators: Advanced separation techniques use air currents and gravity to efficiently segregate paddy from un-milled rice.

- Storage Silos: Modern silos incorporate climate control systems to maintain the quality of the stored rice, preventing spoilage.

The remarkable integration of sophisticated software and machinery showcases a new era in rice milling that maximizes production while maintaining high-quality output. Central to these advancements is the use of Big Data and IoT (Internet of Things), enabling operators to monitor machinery performance in real-time and make informed decisions. The versatility of milling technology can be summarized in the table below:

| Technology | Benefit |

|---|---|

| Automated Milling Systems | Increases efficiency and reduces operational costs |

| Precision Milling | Enhances grain quality and reduces waste |

| Data Analytics | Optimizes production strategies and reduces downtime |

Through such advancements, modern rice mills are not only ensuring a consistent supply of quality rice but also redefining the standards in the milling industry. As technology progresses, the future of rice milling will likely see even greater innovations, paving the way for sustainability and enhanced food security on a global scale.

Sustainability Practices in Rice Production and Processing

In the intricate tapestry of rice production, sustainable practices play a vital role in ensuring the longevity of this precious crop. Integrated Pest Management (IPM) and organic practices are increasingly embraced, creating a harmonious relationship between farming and the environment. By applying measures such as crop rotation, the introduction of beneficial insects, and the use of organic fertilizers, farmers not only enhance soil health but also promote biodiversity. This approach minimizes dependency on chemical inputs, fostering an ecosystem that supports both the farmer and the land. Furthermore, the incorporation of water-efficient irrigation techniques, such as drip irrigation and rainwater harvesting systems, has emerged as a cornerstone of sustainable rice cultivation, effectively mitigating water scarcity while maximizing yield potential.

The journey towards sustainability doesn’t cease in the fields; it extends into the processing phase as well. Rice mills are adopting energy-efficient technologies and waste reduction strategies that emphasize recycling and reusing byproducts. For instance, rice husks, often discarded, can now be transformed into biofuel, providing an alternative energy source for milling operations. Moreover, many mills are implementing renewable energy sources, like solar panels, to power their facilities. The following table summarizes some of these innovative practices and their impacts:

| Practice | Impact |

|---|---|

| Integrated Pest Management | Reduces chemical usage, promotes biodiversity |

| Water-efficient irrigation | Conserves water resources, improves yields |

| Biofuel from rice husks | Provides alternative energy, minimizes waste |

| Use of renewable energy | Decreases carbon footprint, lowers operational costs |

Maximizing Efficiency: Best Practices for Operating a rice mill plant

Operating a rice mill plant efficiently hinges on the implementation of strategic practices that streamline processes and enhance productivity. One essential aspect is optimizing workflow through the arrangement of machinery and equipment. By ensuring that each step of the milling process—cleaning, husking, polishing, and packaging—is logically sequenced, downtime can be minimized. Furthermore, regular maintenance schedules for all machinery help to avoid unexpected breakdowns. Incorporating modern technology, such as automation and real-time monitoring systems, can significantly improve efficiency by providing accurate data on processing times and equipment performance.

In addition to workflow optimization, staff training plays a critical role in maximizing operational efficiency. Ensuring that employees are well-trained not only in the technical aspects of machine operation but also in quality control measures leads to better product outcomes. Empowering workers with knowledge about the importance of their roles fosters a culture of accountability and excellence. Regular workshops and updates on best practices can keep staff motivated and informed. establishing a feedback loop where team members can suggest improvements based on their experiences on the floor is invaluable for continuous enhancement of processes.

| Practice | Benefit |

|---|---|

| Streamlined Equipment Layout | Reduces processing time and minimizes waste. |

| Regular Maintenance | Avoids unexpected breakdowns and improves machinery lifespan. |

| Staff Training | Enhances technical skills and boosts product quality. |

| Feedback Initiatives | Encourages continuous process improvement and innovation. |

The Conclusion

As we draw the curtain on our exploration of the rice mill plant journey, we find ourselves reflecting on the intricate dance of tradition and innovation that defines this vital industry. Each step—from the paddy fields where the journey begins, through the rhythmic hum of machinery, to the final grain quietly resting in packaging—tells a story of dedication, community, and resilience.

The heart of grain, embodied in rice, offers not just sustenance but a rich tapestry of culture and connection. As we continue to delve deeper into sustainable practices and technological advancements, the rice mill stands as a testament to the harmony we can achieve between nature and industry. This journey is ongoing, inviting us to appreciate not only the grains that nourish us but also the hands and hearts that bring them to our tables.

Thank you for joining us on this insightful voyage. As we move forward, let us remain curious and committed to understanding the layers behind the food we consume, ensuring that we honor the past while nurturing a sustainable future.