In a world where efficiency and sustainability are no longer luxuries but necessities, the humble grain is undergoing a remarkable transformation. Once milled by hand in small, labor-intensive operations, rice production is stepping into a new era with the rise of auto rice mills. These modern marvels not only streamline the milling process but also promise to enhance the quality and accessibility of one of the world’s most vital staples. As we explore this evolution, we’ll uncover how auto rice mills are reshaping the agricultural landscape, empowering farmers, and ultimately turning simple grains into a source of goodness for communities everywhere. Join us on a journey through innovation and tradition, where the story of rice is no longer just about sustenance, but about fostering progress and prosperity.

The Evolution of Grain Processing Technologies

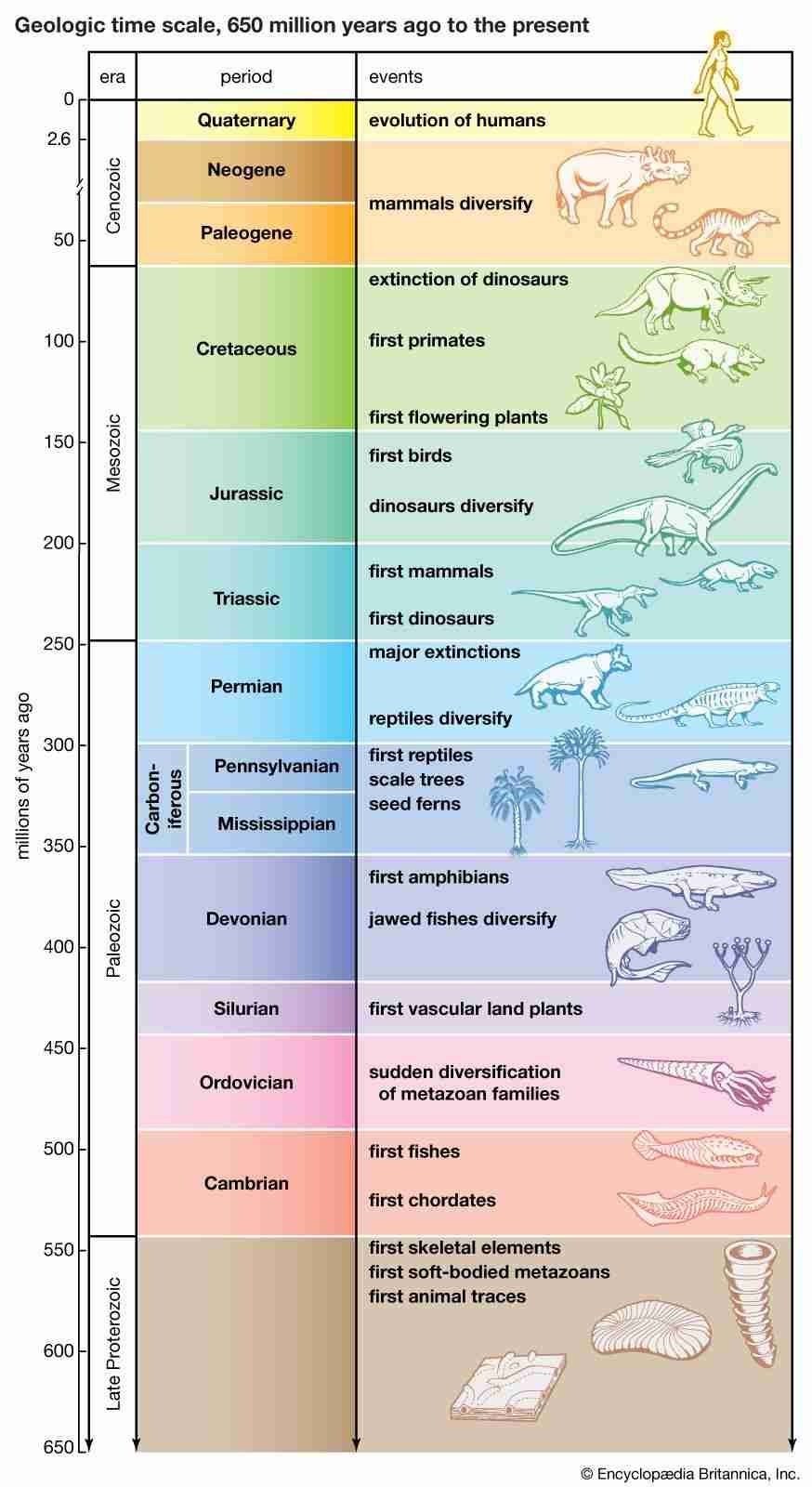

Throughout history, grain processing technologies have undergone significant transformations that reflect advancements in both science and engineering. From the primitive hand tools used by ancient civilizations to the sophisticated machinery we see today, the evolution of grain processing has been marked by a continual pursuit of efficiency, quality, and sustainability. Key milestones in this journey include:

- Stone Mills: The earliest method, using large stones to grind grains, which paved the way for more advanced techniques.

- Water and Wind Power: The introduction of watermills and windmills allowed for larger-scale processing and reduced manual labor.

- Steam Power: The industrial revolution brought steam engines that dramatically increased processing speed and capacity.

- Automated Systems: Modern advancements incorporate sensors and technology for precision and consistency in grain milling.

In recent years, the rise of auto rice mills has epitomized this evolution, blending traditional practices with cutting-edge innovations. These facilities boast features such as:

| Feature | Benefits |

|---|---|

| High Efficiency | Reduces processing time and energy consumption, maximizing output. |

| Quality Control | Integrated systems ensure uniformity and high-quality production. |

| Waste Minimization | Advanced technologies increase the recovery rates of usable grain. |

| Automation | Less reliance on manual labor, improving safety and labor conditions. |

This blending of tradition and technology not only enhances productivity but also aligns with contemporary demands for sustainable practices in the agricultural sector. As the global population continues to grow, the importance of efficient grain processing has never been clearer, paving the way for future advancements that promise to revolutionize how we transform grain into nourishment.

Maximizing Efficiency in Auto Rice Mills

In the world of auto rice mills, optimizing processes is vital for enhancing productivity and reducing operational costs. By implementing advanced techniques such as automation and data analytics, mill operators can streamline their operations significantly. For instance, employing state-of-the-art milling machines with programmable settings allows for a higher level of precision in rice processing. Incorporating real-time monitoring systems can help identify bottlenecks, leading to quicker adjustments and improved throughput. Furthermore, investing in staff training ensures that employees are well-versed in utilizing these technologies effectively, thereby maximizing the benefit of new systems.

Integrating sustainability measures is another effective way to boost efficiency in auto rice mills. The use of renewable energy sources like solar panels and biomass not only reduces electricity costs but also contributes to environmental stewardship. Mills can also implement water recycling systems to minimize waste, reinforcing their commitment to sustainability while improving their bottom line. By analyzing their processes through a lens of continuous improvement, rice mill operators can further enhance their operational efficiency. Below is a comparison of traditional vs. auto rice mill efficiency metrics:

| Metric | Traditional Rice Mill | Auto Rice Mill |

|---|---|---|

| Processing Time | 3-4 hours per batch | 1-2 hours per batch |

| Labor Requirement | 10-12 workers | 3-4 workers |

| Energy Consumption | High | Low |

Sustainability Practices in Modern Rice Production

In the quest for sustainable agriculture, modern rice production has embraced various innovative practices aimed at minimizing environmental impact while maximizing yield. One prominent approach is the adoption of precision farming technologies, which utilize sensors and data analytics to optimize water use, fertilizer application, and pest control. These technologies allow farmers to apply resources precisely where and when they are needed, reducing waste and enhancing productivity. Additionally, the implementation of crop rotation and integrated pest management strategies ensures soil health and reduces dependency on chemical inputs, promoting a more holistic approach to rice cultivation.

Furthermore, the rise of auto rice mills has significantly contributed to sustainability within the industry. These mills are designed with energy-efficient operations and often integrate renewable energy sources, such as solar power, to reduce their carbon footprint. The processing methods employed in auto mills frequently prioritize waste reduction and by-product utilization, further contributing to a circular economy in rice production. Key benefits include:

- Reduced water consumption through closed-loop systems

- Minimized greenhouse gas emissions via low-energy machinery

- Support for local economies by sourcing grain from nearby farmers

Enhancing Product Quality Through Automation

Automation in the rice milling process is not just a trend; it’s a significant advancement that ensures superior quality and consistency in every grain. By integrating cutting-edge technology, auto rice mills minimize human error while maximizing efficiency, leading to a product that meets or exceeds customer expectations. The benefits of automating the milling process include:

- Precision: Automated systems calibrate machinery to achieve optimal milling conditions, ensuring each grain is processed uniformly.

- Consistency: With constant monitoring and control, automation reduces variability in the final product, resulting in uniformity in texture and appearance.

- Efficiency: Fast-paced operations not only speed up production but also lower energy consumption, making the process more environmentally friendly.

Furthermore, the quality control inherent in automated systems leads to improved food safety standards. By utilizing real-time data analytics, mills can assess the quality of rice at various stages, allowing for quick adjustments that uphold high standards. The introduction of advancements such as:

| Feature | Benefit |

|---|---|

| Smart Sensors | Monitor moisture levels to prevent spoilage. |

| Integrated Software | Tracks production metrics for continuous improvement. |

| Automated Quality Checks | Ensures compliance with grading standards. |

highlight how technology is transforming the rice sector into a highly efficient and quality-driven industry, paving the way for greater market competitiveness on a global scale. The shift towards automation not only meets the demands of a burgeoning population but also caters to a discerning clientele that increasingly prioritizes quality. As automated processing becomes the new norm, consumers can enjoy rice that is not only nutritious but also consistently superb in quality.

In Summary

As we draw the curtain on our exploration of the transformative journey from grain to goodness, it becomes clear that auto rice mills stand as beacons of innovation in the agricultural landscape. This evolution isn’t merely about machinery; it speaks to the heart of sustainability, efficiency, and an ever-growing commitment to feeding a global population with higher standards of quality and care.

The rise of these automated systems resonates across the fields, touching the lives of farmers, entrepreneurs, and consumers alike. With each kernel processed, auto rice mills are not just altering the economics of rice production; they’re reshaping futures, fostering communities, and paving the way for advancements we’ve yet to imagine.

As we move forward, embracing the possibilities that technology presents in agriculture, let us remember the simple grain that fuels much of our world. Each step along this path from field to table holds the potential for goodness—both in our plates and in the lives we touch along the way. Whether you are a farmer, a business owner, or an informed consumer, your role in this narrative is essential. Together, let’s continue to champion progress and cultivate a more sustainable future, one grain at a time.