In the heart of agricultural innovation lies a remarkable evolution in rice processing technology: the combined rice mill machine. As global demand for rice continues to surge, farmers and millers alike seek a balance between quality and efficiency in their production methods. These multifunctional machines, which seamlessly integrate various milling processes, promise to revolutionize the way rice is processed—from husking and whitening to polishing—while significantly reducing labor and time. In this article, we will explore the many facets of combined rice mill machines, uncover their benefits, and illustrate how they are paving the way for a more sustainable and productive future in rice milling. Join us as we unlock the potential of these engineered marvels and discover their indispensable role in modern agriculture.

Exploring the Mechanics of Combined Rice Mill Machines

Combined rice mill machines have revolutionized the rice processing industry by merging multiple functions into a single, compact unit. This innovation not only maximizes efficiency but also minimizes the space and labor typically required in traditional milling setups. The intricate mechanics of these machines involve a series of distinct components working harmoniously to achieve optimal outcomes. Here are some key features of these versatile machines:

- Hulling mechanisms – effectively remove the outer layers of husk from rice grains.

- Polishing units – enhance the appearance and quality of milled rice through gentle abrasion.

- Grading systems – classify rice based on size and quality, ensuring uniformity.

- Continuous operation – allows for a steady flow of production, reducing downtime.

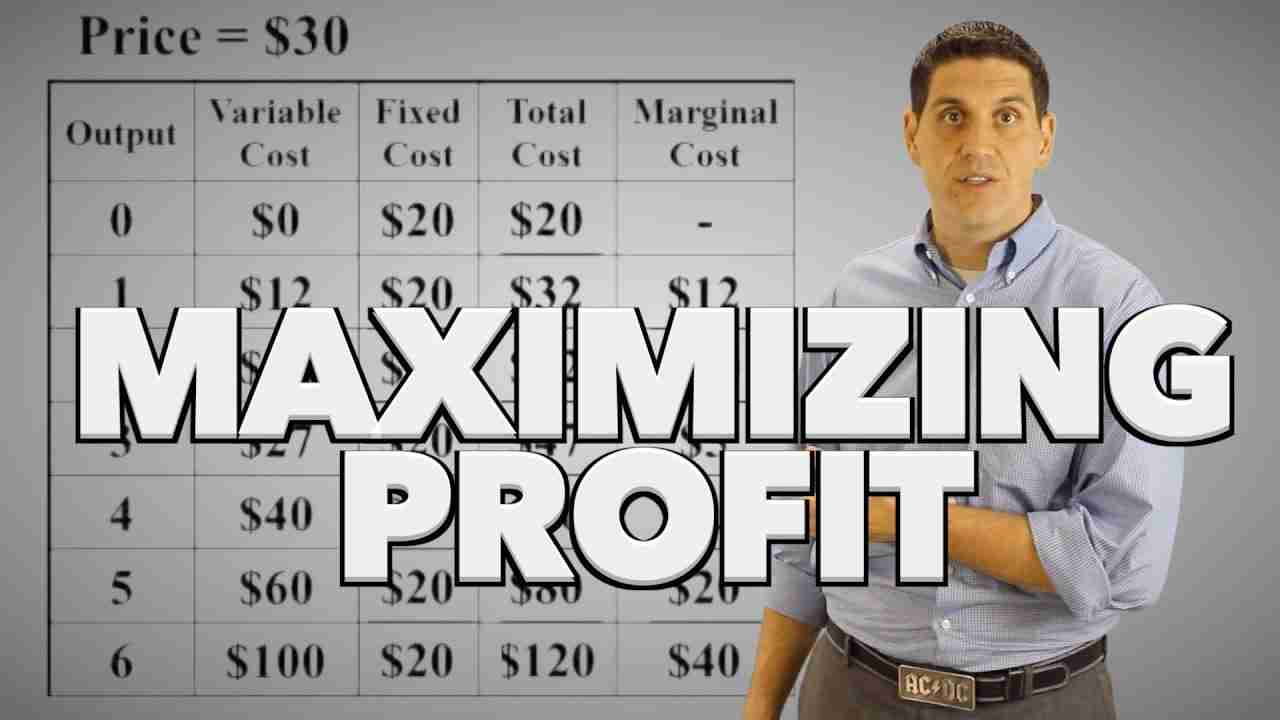

The operation of combined rice mill machines is both sophisticated and user-friendly, designed to accommodate various types of rice and milling preferences. By utilizing adjustable settings for different grains, these machines offer incredible flexibility. The efficiency of rice milling can be further evaluated through the following table, which illustrates key performance metrics:

| Performance Metric | Value |

|---|---|

| Processing Capacity | 100-200 kg/h |

| Power Consumption | 4-6 kW |

| Grain Recovery Rate | 70-80% |

| Maintenance Frequency | Monthly |

With such impressive specifications, it’s no wonder that combined rice mill machines are becoming the backbone of modern rice processing. The advanced technology not only cuts costs but also streamlines operations, making it a savvy investment for rice millers looking to amplify their production capabilities.

Maximizing Productivity through Versatile Design Features

For those in the grain processing industry, the integration of versatile design features in combined rice mill machines is a game changer. These machines offer a streamlined approach to processing, allowing for a range of functionalities to be managed seamlessly. With features such as automatic husking, polishing, and grading, users can accomplish multiple tasks without the need for several separate machines. This versatility not only saves space but also reduces labor costs, leading to increased operational efficiency:

- Space Efficiency: By combining processes, businesses can maximize their production area.

- Cost-Effectiveness: Fewer machines mean lower maintenance costs and reduced energy consumption.

- Ease of Use: Integrated controls simplify operation, making it easier for staff to manage the milling process.

The adaptability of these machines extends to their ability to handle various types of rice and other grains, contributing to the overall productivity of grain processing operations. Users enjoy features like adjustable milling settings that cater to different grain types, ensuring that every batch meets desired quality standards. The effective use of innovative technology, such as real-time monitoring systems, can enhance decision-making and permit on-the-fly adjustments to maintain optimal performance:

| Feature | Benefit |

|---|---|

| Adjustable Milling Settings | Targets specific grain textures to maintain quality. |

| Real-Time Monitoring | Enables quick adjustments to improve process efficiency. |

| Multi-Functional Capability | Processes different grains, expanding operational versatility. |

Optimizing Operational Costs: Maintenance and Energy Efficiency

Reducing operational costs in rice milling is critical, especially in a competitive market. By investing in automated combined rice mill machines, businesses can significantly achieve improved maintenance efficiency. These machines are designed to streamline the milling process by integrating multiple functions—from husking to polishing—into one compact unit. This not only cuts down on the need for additional machinery but also minimizes downtime associated with repairs and maintenance. Regular maintenance schedules can be easily implemented, reducing the likelihood of costly breakdowns and extending the lifespan of the equipment.

Moreover, energy efficiency is another vital aspect that contributes to cost optimization. Modern combined rice mill machines are equipped with advanced technology that maximizes output while minimizing power consumption. Features such as automatic load sensing and variable speed drives allow these machines to adjust their energy usage based on workload. This adaptability can result in significant savings on electricity costs. When considering energy-efficient practices, operators can also benefit from:

- Implementing regular energy audits

- Utilizing renewable energy sources where possible

- Training staff on best practices for efficient machine operation

By focusing on these areas, rice milling operations can enhance their profitability and environmental sustainability, making a noticeable impact on their bottom line.

Choosing the Right Combined Rice Mill for Your Business Needs

When selecting a combined rice mill, it’s essential to assess the specific requirements of your business. A thorough understanding of your operation can guide you toward a machine that not only meets your current needs but also has the capacity to grow with you. Consider the following factors:

- Processing Capacity: Evaluate the volume of rice you plan to mill daily. Ensure the machine can handle your production demands efficiently.

- Feature Set: Look for machines with multifunction capabilities, including milling, husking, and polishing, to maximize efficiency.

- Durability: Invest in a model crafted from high-quality materials, as it will determine the longevity and reliability of your operations.

To further refine your choices, it’s beneficial to compare various models side by side. The table below summarizes key specification aspects that can assist you in making an informed decision:

| Model | Capacity (kg/h) | Power Consumption (KW) | Price Range ($) |

|---|---|---|---|

| Model A | 500 | 20 | 3000 - 3500 |

| Model B | 1000 | 30 | 4500 - 5000 |

| Model C | 1500 | 40 | 6000 – 6500 |

Ultimately, combining these evaluations will greatly aid in selecting a combined rice mill that aligns with your operational goals and economic constraints. Understanding the nuances of each model and how they integrate into your workflow will unlock the true efficiency that these versatile machines promise.

To Conclude

In a world where efficiency reigns supreme, the combined rice mill machine emerges as a beacon of innovation, redefining the rice production landscape. By interweaving various processes into a singular, cohesive unit, these machines not only streamline operations but also enhance productivity, reducing both time and labor costs. As we’ve explored, the adaptability of these machines caters to the diverse needs of farmers and millers, transforming challenges into opportunities for growth.

As rice continues to be a staple food for billions, unlocking the full potential of its production through advanced machinery is more crucial than ever. The combined rice mill machine stands at the forefront of this evolution, symbolizing a harmonious blend of tradition and technology. As we move forward, embracing such innovations will be vital for ensuring food security while empowering communities along the way.

the journey toward maximizing efficiency in rice milling is just beginning, and together, we have the power to shape a sustainable future—one grain at a time.