In a world where innovation intersects with tradition, the humble grain has become the canvas for a remarkable transformation. As global demand for high-quality rice continues to soar, the introduction of mini rice polisher machines is turning heads in agriculture and food processing alike. These compact marvels, designed to enhance the efficiency and quality of rice polishing, are reshaping how we approach grain production. Gone are the days when processing required large, cumbersome equipment; today, technology is making it possible for small-scale farmers and entrepreneurs to refine their products with precision and ease. This article delves into the rise of mini rice polishers, exploring their impact on the industry, the benefits they offer to producers, and the potential they hold for improving sustainability in a sector that feeds billions. Join us as we uncover how these innovative machines are revolutionizing the way we think about grain, one polished kernel at a time.

The Evolution of Grain Processing and the Emergence of Mini Rice Polishers

The journey of grain processing has undergone significant transformations throughout history. From ancestral techniques using rudimentary tools to advanced machinery, the industry has seen a dramatic shift in efficiency and precision. Initially, grains were manually processed using wooden mortars or stone grinders, which required immense labor and time. The onset of the Industrial Revolution introduced mechanized milling, leading to the emergence of large-scale production facilities that could process vast quantities of rice and other grains. This shift not only enhanced productivity but also made rice accessible to a broader population, fostering food security and international trade.

In recent years, the advent of mini rice polishers has revolutionized the grain processing landscape once again. These compact machines cater to the growing demand for small businesses and farms seeking efficient solutions without the need for large-scale equipment. Notable features of mini rice polishers include:

- Energy Efficiency: Designed to consume less power while delivering remarkable polishing results.

- Space-Saving Design: Ideal for small facilities or home-based businesses, minimizing the footprint.

- Improved Grain Quality: Enhances the appearance and taste of rice, appealing to discerning consumers.

The shift towards mini rice polishers symbolizes a commitment to sustainable agriculture and local food production, making it feasible for entrepreneurs to enter the grain market with confidence. This innovation not only optimizes grain processing but also supports the revival of traditional rice brands, allowing small-scale producers to compete in a dynamic marketplace.

Efficiency and Precision: How Mini Rice Polishers Transform the Milling Industry

In an industry where every grain counts, the introduction of mini rice polishers has brought about a significant transformation, redefining the standards of efficiency and precision. These compact machines allow millers to achieve superior polishing results by combining advanced technology with user-friendly designs. With their optimized size, they can be integrated into smaller milling operations without sacrificing performance. The result is a remarkable enhancement in output quality and quantity, ensuring that each batch of rice is polished to perfection.

One of the key advantages of mini rice polishers is their ability to minimize waste while maximizing product yield. Unlike traditional large-scale machines, these mini versions are engineered for finesse, utilizing innovative polishing techniques that reduce the loss of valuable rice grains. Some of the standout features include:

- Energy efficiency: Consumes less power compared to conventional polishers.

- Compact design: Fits easily into small processing spaces.

- Advanced controls: Provides the ability to customize polishing intensity for different rice varieties.

| Feature | Benefit |

|---|---|

| Automated settings | Reduces manual intervention and enhances consistency. |

| Low noise operation | Creates a more pleasant working environment. |

| Durable materials | Ensures long-lasting performance even under heavy usage. |

The ripple effect of integrating mini rice polishers into milling processes can be seen not only in the quality of the rice produced but also in the economic viability for millers. With faster processing times and reduced operational costs, these machines empower producers to meet rising consumer demands for high-quality rice while maintaining competitive pricing. This evolution marks a step toward more sustainable milling practices, paving the way for smaller players in the industry to thrive and contribute to local economies.

Sustainability in Grain Processing: Eco-Friendly Benefits of Mini Rice Polishers

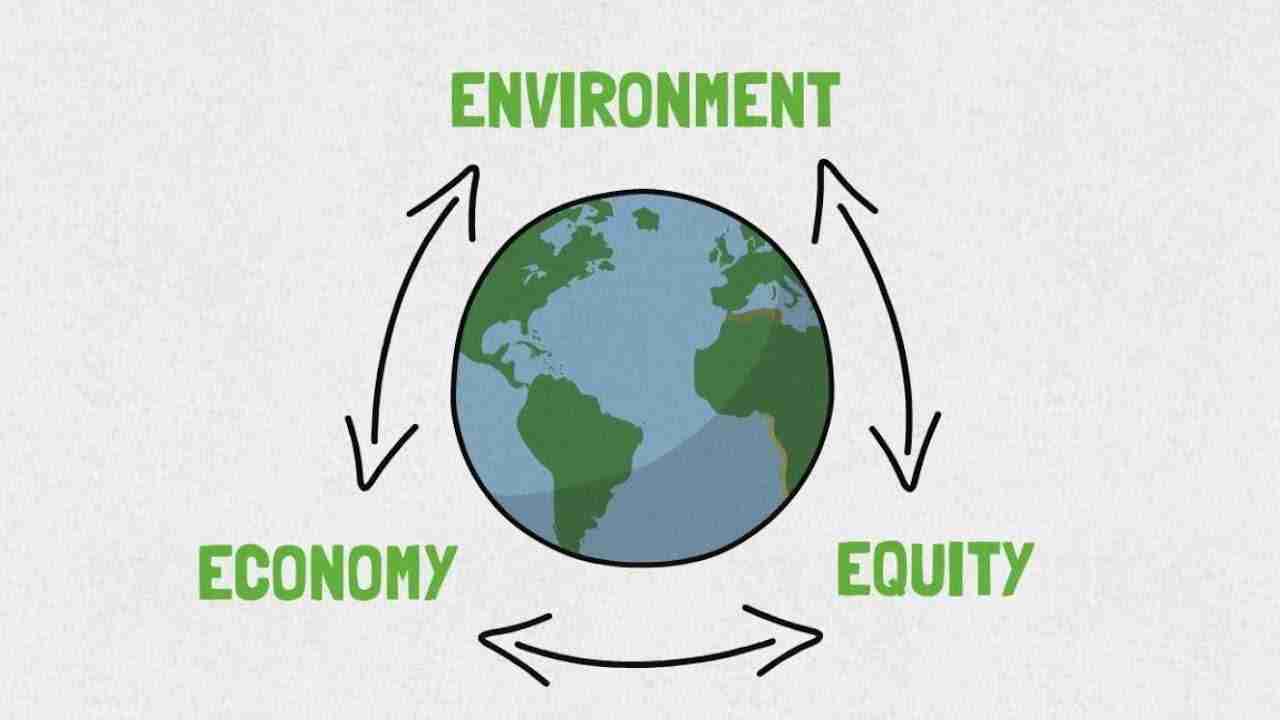

As the movement towards sustainable agriculture gains momentum, mini rice polishers are emerging as a game-changing technology that not only enhances the efficiency of grain processing but also prioritizes eco-friendliness. These compact machines are designed to consume significantly less energy compared to their larger counterparts, leading to lower carbon emissions and a reduced ecological footprint. Additionally, by employing innovative polishing techniques, they preserve more nutrients in the rice, ensuring that the product delivered to consumers is not only healthier but also minimizes food waste.

Another noteworthy advantage of mini rice polishers is their ability to facilitate local economies through small-scale processing. By decentralizing grain polishing, these machines enable farmers and small business owners to process rice closer to production sites, which helps reduce transportation emissions. Furthermore, as they utilize renewable energy sources and biodegradable materials, these machines contribute to a circular economy. Here are some eco-friendly benefits:

- Lower energy consumption – More efficient than traditional machines.

- Minimal waste generation – Optimizes the use of the entire grain.

- Supporting local production – Reduces the carbon footprint associated with transportation.

- Utilization of sustainable materials – Contributing to eco-friendly manufacturing practices.

| Feature | Traditional Polishers | Mini Rice Polishers |

|---|---|---|

| Energy Consumption | High | Low |

| Waste Output | Significant | Minimal |

| Transportation Emissions | High | Reduced |

| Cost of Production | Higher | Lower |

Choosing the Right Model: Key Features to Consider for Optimal Performance

When selecting a mini rice polisher machine, several crucial features can significantly influence its performance and efficiency. Capacity is paramount; consider the volume of rice you typically process and ensure the machine can handle your requirements comfortably. A model with a higher capacity can save time and energy, especially for small business owners. Additionally, adjustability plays a key role in achieving the desired polish; look for machines that allow you to customize the polishing settings to suit different grain types, thus providing flexibility for various operations.

Another essential feature is energy efficiency. Machines designed to minimize energy consumption not only reduce operational costs but also lessen environmental impact. Furthermore, the durability of the materials used in construction should not be overlooked; opt for machines built from high-quality components that can withstand prolonged use. To summarize the considerations, here’s a quick reference table:

| Feature | Description |

|---|---|

| Capacity | Choose based on your processing needs. |

| Adjustability | Allows customization for different rice types. |

| Energy Efficiency | Reduces operating costs and environmental impact. |

| Durability | Opt for high-quality materials for longevity. |

Final Thoughts

As the agricultural landscape continues to evolve, the emergence of mini rice polisher machines represents a transformative leap in grain processing technology. These compact marvels are not merely tools; they symbolize a shift toward efficiency, sustainability, and accessibility for farmers around the globe. With their ability to streamline operations and enhance the quality of rice, mini polishers are forging pathways for small-scale producers to thrive in an increasingly competitive market.

As we look to the future of grain processing, the integration of such innovative machinery will undoubtedly play a pivotal role in addressing global food demands and supporting rural livelihoods. By fostering greater engagement and empowerment within local farming communities, these machines are more than just a means to an end—they are a catalyst for change.

In this age of agricultural revolution, it’s essential we recognize the significance of these advancements, not just in technology but in the stories of those who benefit from them. The rise of mini rice polishers is a testament to the power of ingenuity, reminding us that even the smallest innovations can have far-reaching impacts. So, as we turn our gaze toward an era of smarter farming, let us embrace the possibilities that lie ahead and continue to support the advancements shaping the world of grain processing.