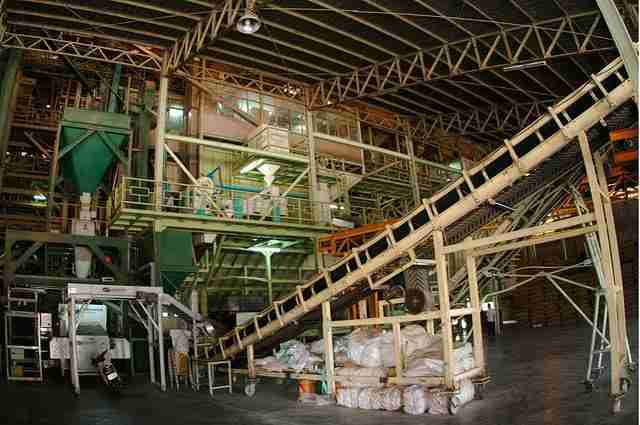

In the heart of culinary traditions around the world lies a staple that has nourished countless generations: rice. From its humble beginnings in verdant paddies to the fragrant grains that grace our plates, the journey of rice is anything but ordinary. However, this journey hinges on a crucial process — milling. Enter the realm of rice milling machines, where technology meets tradition to transform raw grains into perfectly polished pearls. In this comprehensive guide, we will explore the transformative world of complete rice milling machines, uncovering the intricacies of their functions, innovations that drive efficiency, and the impact they have on rice quality and availability. Whether you are a rice mill operator, a farmer, or simply a culinary enthusiast curious about the behind-the-scenes magic, this guide will equip you with the knowledge to navigate the fascinating landscape of rice milling. Join us as we delve into the mechanics, advantages, and future trends that define this essential aspect of the rice industry.

Understanding the Rice Milling Process for Optimal Grain Quality

The rice milling process is a meticulous journey that transforms harvested paddy into the pristine grains consumers expect. This process involves several crucial steps that directly influence the quality of the final product. From cleaning the paddy to the hulling phase, each step must be executed with precision. After hulling, the brown rice undergoes polishing to enhance its appearance and remove the bran layer, making it more appealing to consumers. Notably, the choice of milling machine plays a pivotal role in determining grain quality, as it can affect the integrity and nutritional value of the rice.

Additionally, maintaining optimal settings throughout the milling process is key to achieving consistent results. Consider the following factors that can influence the quality of the milled rice:

- Moisture Content: Ideal moisture levels help in preventing breakage.

- Machine Calibration: Properly calibrated machines ensure minimal loss during milling.

- Duration of Milling: Over-milling can lead to excessive heat generation, which affects flavor and nutrition.

To assess the effectiveness of various milling machines, a comparison table can illuminate their differing capabilities:

| Machine Type | Yield Efficiency (%) | Operating Speed (kg/h) |

|---|---|---|

| Small Scale Mill | 70-80 | 150 |

| Medium Scale Mill | 80-90 | 500 |

| Large Scale Mill | 90-95 | 2000 |

Understanding these aspects of the milling process empowers producers to make informed choices about their equipment and methods, ultimately leading to better-quality rice that meets market demands.

Essential Features to Look for in Modern Rice Milling Machines

Modern rice milling machines have evolved to incorporate a variety of essential features that enhance efficiency and performance. These machines should prioritize high capacity and speed, allowing mills to process larger quantities of rice in shorter durations. The inclusion of automated control systems not only simplifies operation but also minimizes human error, ensuring optimal results. Furthermore, energy efficiency has become a key focus, with many machines now utilizing advanced technologies to reduce power consumption, making them more environmentally friendly and cost-effective to run.

Another crucial aspect to consider is the technology used for milling. Machines equipped with multiple milling stages, such as husking, whitening, and polishing, consistently produce high-quality rice with lower breakage rates. Additionally, the presence of dust and chaff separators can significantly improve the final product’s cleanliness, enhancing marketability. Lastly, easy maintenance features, such as removable parts and built-in diagnostic tools, can help operators maintain the machines’ longevity and performance over time, ensuring a smart investment for any rice milling business.

| Feature | Description |

|---|---|

| High Capacity | Allows processing of large quantities quickly. |

| Automated Systems | Reduces human error through advanced technologies. |

| Energy Efficiency | Minimizes power usage and operational costs. |

| Milling Technology | Ensures high-quality rice with reduced breakage. |

| Maintenance Features | Easy to clean and service for better longevity. |

Comparative Analysis of Top Rice Milling Technologies on the Market

The landscape of rice milling technologies is evolving rapidly, with innovations aimed at enhancing efficiency and output quality. When considering the top rice milling machines, several factors must be evaluated to make an informed decision. Notably, technology options vary in terms of energy consumption, processing speed, and overall maintenance requirements. Key technologies currently dominating the market include:

- Traditional Hullers: Ideal for small-scale operations, these machines rely on manual labor and basic mechanization.

- Modern Satake Machines: Known for their high throughput capacity and ability to preserve grain quality.

- Compact Integrated Millers: Designed for efficiency, these machines combine multiple functions in one compact unit.

- Automated Rice Milling Systems: Featuring advanced digital controls, they optimize production and reduce human error.

To facilitate a clearer understanding of these technologies, the following table summarizes essential specifications and attributes:

| Technology Type | Processing Speed (kg/h) | Power Requirement (kW) | Grain Quality |

|---|---|---|---|

| Traditional Hullers | 500 | 2-3 | Low |

| Modern Satake Machines | 1000-2000 | 10-15 | High |

| Compact Integrated Millers | 600-1200 | 5-8 | Medium |

| Automated Rice Milling Systems | 1500+ | 15-20 | Very High |

Maintenance Tips for Maximizing the Lifespan of Your Rice Milling Equipment

To ensure your rice milling equipment remains in peak condition, regular maintenance practices are essential. Start by creating a scheduled routine to inspect vital components of the machine. Focus on areas such as the husk removal system, whitening chamber, and grade separation. Utilize the following tips to enhance the longevity of your equipment:

- Daily Cleaning: Remove rice husks and dust to prevent buildup that could cause operational issues.

- Lubrication: Regularly lubricate all moving parts to reduce wear and tear.

- Calibration: Regularly check and calibrate the machinery settings to ensure optimal performance.

Another crucial aspect of maintenance involves scheduled professional servicing. Hiring a qualified technician at defined intervals will not only help identify potential problems but also keep your equipment operating efficiently. You can keep track of maintenance activities in a systematic way with a simple table:

| Maintenance Activity | Frequency | Responsible Party |

|---|---|---|

| Daily Cleaning | Every day | Operator |

| Lubrication Check | Weekly | Operator |

| Professional Inspection | Quarterly | Technician |

To Wrap It Up

As we conclude our deep dive into the fascinating world of rice milling machines, it’s clear that these remarkable devices serve as a bridge, transforming raw grains into the staple we depend on daily. From the meticulous selection of equipment to the intricate processes that maximize yield and quality, understanding the nuts and bolts of rice milling is essential for farmers, millers, and anyone passionate about sustainable food production.

In an ever-evolving agricultural landscape, investing in the right milling technology not only enhances efficiency but also uplifts communities by ensuring that the fruits of labor reach the table in their finest form. Whether you’re a seasoned professional or new to the field, this guide equips you with the knowledge to navigate the complexities of rice milling.

As we look ahead, the future of rice processing is bright, marked by innovation, sustainability, and a commitment to excellence. Armed with this knowledge, you are now better prepared to embark on this journey of transformation, ensuring that every grain tells a story of care, craftsmanship, and culinary delight. Thank you for joining us on this exploration – may your milling endeavors pave the way for a more food-secure tomorrow!