Unlocking Potential: Exploring the Rice Mill Plant Revolution

In the heart of agriculture, where tradition meets innovation, lies an industry ripe for transformation—the rice milling sector. As one of the world’s staple foods, rice sustains billions yet has often been entangled in outdated practices that hinder efficiency and quality. However, a quiet revolution is brewing, driven by advancements in technology, sustainable practices, and a renewed focus on unlocking the full potential of rice production. This article delves into the dynamic landscape of modern rice mill plants, exploring how they are redefining the milling process, enhancing productivity, and fostering economic development in farming communities. Join us as we embark on a journey through the intricate machinery, cutting-edge techniques, and the visionary minds that are shaping the future of rice milling—unlocking a world of possibilities for farmers, millers, and consumers alike.

The Evolution of Rice Mill Technology and Its Impact on Agricultural Efficiency

The journey of rice milling technology mirrors the evolution of agriculture itself, transitioning from manually operated tools to highly sophisticated machinery. Initially, rice processing involved simple, labor-intensive methods, where farmers relied on hand-operated mortar and pestle techniques. Over time, as populations grew and demand for rice increased, mechanical innovations emerged. The introduction of the first motorized rice mills significantly enhanced productivity, allowing for quicker processing times and less physical strain on farmers. Recent advancements harness cutting-edge technologies, including automation and IoT integration, enabling real-time monitoring of milling processes and ensuring optimal efficiency.

As the rice milling industry continues to evolve, its impact on agricultural efficiency becomes increasingly clear. The implementation of modern milling equipment not only maximizes yield but also minimizes wastage. Some key benefits of contemporary rice processing technologies include:

- Enhanced precision in husking and whitening processes

- Reduced energy consumption, leading to lower operating costs

- Improved product quality, resulting in higher market value

- Streamlined workflows that allow for greater scalability

The table below highlights the comparison of traditional versus modern milling technologies, showcasing their impact on efficiency:

| Feature | Traditional Milling | Modern Milling |

|---|---|---|

| Processing Time | Up to 50 hours/ton | 10 hours/ton |

| Labor Intensity | High | Low |

| Energy Efficiency | Low | High |

| Product Yield | Low | High |

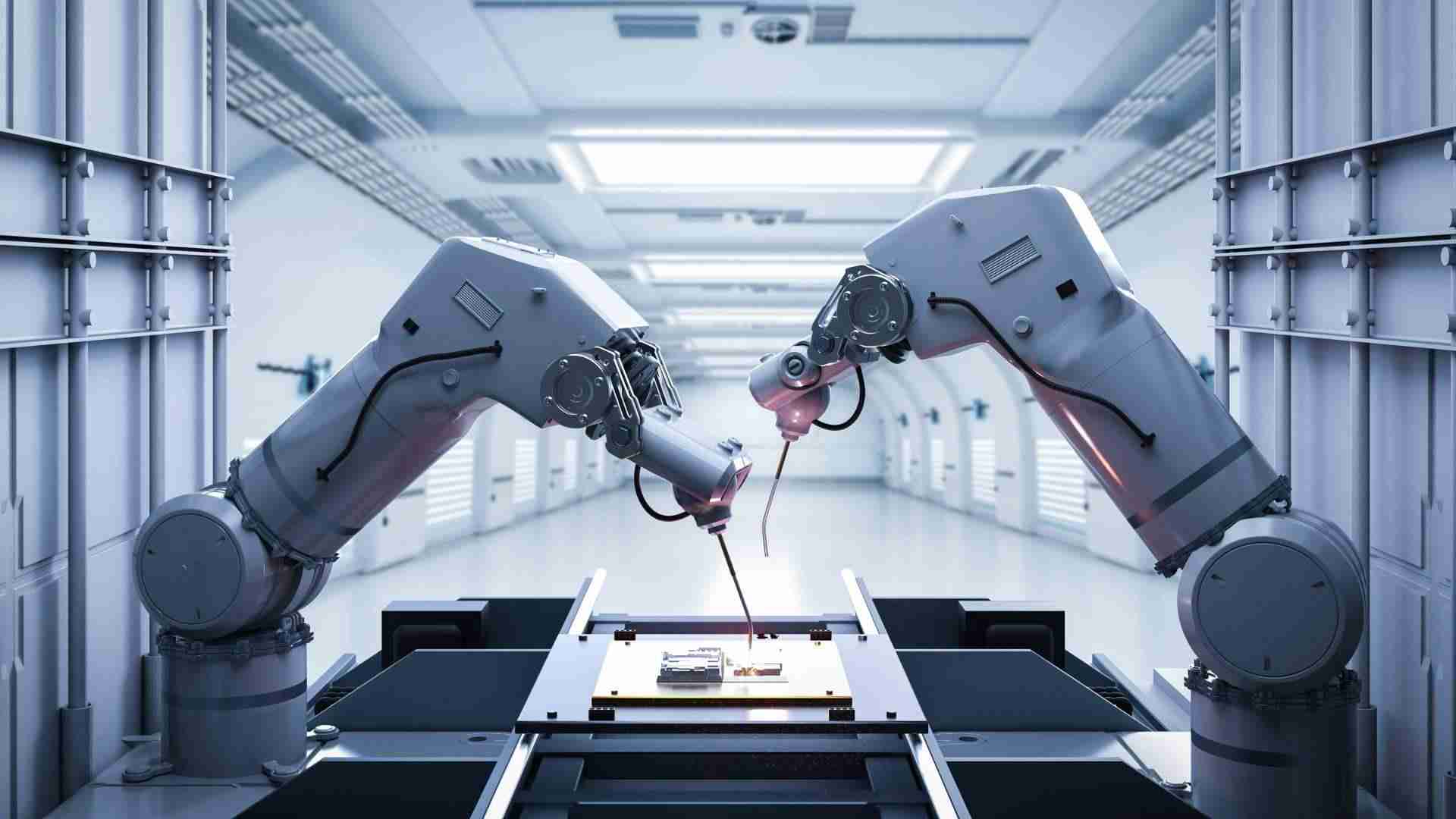

Harnessing Automation for Enhanced Productivity in Rice Milling Operations

In the competitive landscape of rice milling, automation serves as a game changer, streamlining processes and enhancing overall productivity. By integrating advanced technologies, mills can significantly reduce manual labor, minimize errors, and accelerate production times. Automation technologies empower operators to monitor various aspects of milling, from quality control to supply chain management, through intuitive interfaces. Key benefits of automation in rice milling include:

- Improved Efficiency: Automated systems can operate continuously, drastically increasing output while maintaining high precision.

- Consistent Quality: Smart sensors and algorithms ensure uniform grading and processing standards, enhancing the quality of the final product.

- Data Analytics: Real-time data collection enables mills to analyze trends and improve decision-making processes.

- Cost Reduction: Automation helps lower labor costs and reduces waste through optimized resource management.

Additionally, the implementation of robotics for tasks such as sorting, packaging, and inventory management further optimizes operations, allowing human talent to focus on strategic tasks that drive innovation. The transformation isn’t just about machinery; it’s about cultivating a culture of efficiency and continuous improvement across the facility. The following table highlights the key technologies revolutionizing rice milling:

| Technology | Function | Benefit |

|---|---|---|

| Automated Sorting Machines | Sorting grains based on size and quality | Enhances product consistency |

| Robotic Packaging Systems | Automating the packaging process | Increases speed and efficiency |

| Data Analysis Software | Monitoring production metrics | Supports informed decision-making |

| AI-Driven Quality Control | Detecting defects in real-time | Reduces waste and enhances quality |

Sustainability Practices in Rice Mill Plants: A Path Toward Environmental Stewardship

In the quest for environmental stewardship, rice mill plants are increasingly embracing innovative sustainability practices that not only enhance operational efficiency but also mitigate their ecological footprint. These facilities are focusing on reducing waste, conserving water, and minimizing energy consumption through various cutting-edge technologies. For instance, many plants have adopted closed-loop water systems that recycle water used during the milling process, ensuring that this vital resource is preserved rather than wasted. Furthermore, the introduction of energy-efficient machinery and renewable energy sources, such as solar panels, is revolutionizing the way rice is processed, significantly lowering greenhouse gas emissions associated with traditional methods.

Moreover, the commitment to sustainability extends beyond the confines of the mill itself. Many rice mill plants are forging partnerships with local farmers to promote sustainable farming practices, thus fostering a more resilient agricultural ecosystem. This collaboration often includes training farmers in eco-friendly cultivation techniques and encouraging the use of organic fertilizers. Additionally, initiatives like converting rice husks into biomass energy not only provide a sustainable energy source for the mills but also create an additional revenue stream for farmers. As these practices continue to evolve, the rice milling industry is poised to transform into a model of sustainability, demonstrating that economic growth and environmental responsibility can go hand in hand.

| Practice | Benefit |

|---|---|

| Water Recycling Systems | Conserves water and reduces costs |

| Energy-Efficient Machinery | Lowers energy consumption and emissions |

| Biomass Energy Conversion | Provides renewable energy and additional income |

| Farmer Collaboration Programs | Encourages sustainable farming practices |

Investing in Workforce Development: Training for the Future of the Rice Milling Industry

To navigate the evolving landscape of the rice milling industry, a dedicated approach towards workforce development is essential. Investing in tailored training programs can equip workers with the necessary skills to meet modern demands. Emphasizing both technical expertise and soft skills creates a comprehensive workforce capable of adapting to new technologies and processes. Key focus areas for training may include:

- Machinery Operation and Maintenance: Understanding the latest milling equipment.

- Quality Control Standards: Implementing stringent quality checks.

- Sustainability Practices: Minimizing environmental impact.

- Safety Protocols: Ensuring a safe working environment.

Moreover, creating partnerships with educational institutions and industry experts can enhance the effectiveness of these training initiatives. Collaborative workshops and hands-on training sessions can bridge the gap between theoretical knowledge and practical application. To visualize the potential impact on the workforce, the following table outlines the benefits of investing in workforce training:

| Benefit | Description |

|---|---|

| Improved Efficiency | Streamlined processes leading to faster production times. |

| Higher Quality Products | Reduction in defects and increased customer satisfaction. |

| Employee Retention | Investing in skills leads to greater job satisfaction. |

| Innovation | Cultivating a culture of continuous improvement and creativity. |

Insights and Conclusions

As we draw the curtain on our exploration of the rice mill plant revolution, it becomes clear that this transformation is not just a shift in machinery or processes—it’s a profound reimagining of the agricultural landscape. The advancements in technology and techniques in rice milling are unlocking potential not only for producers but for entire communities, fostering sustainability, efficiency, and economic growth. As we move forward, the lessons learned from this revolution may serve as a blueprint for other sectors, illustrating the power of innovation in overcoming challenges and maximizing resources. The future of rice milling remains bright, filled with possibilities that promise to nourish not only our plates but also our aspirations for a better tomorrow.