In the heart of agricultural innovation lies a remarkable transformation: the humble grain, a staple of diets worldwide, is being revolutionized through advanced milling technology. At the forefront of this change are combined rice mill machines, which serve not only as a bridge between farm and table but also as a showcase of ingenuity in the food processing industry. These machines seamlessly integrate multiple functions, allowing for the efficient milling of rice while preserving its nutritional integrity and enhancing its market value. As we delve into the world of combined rice mill machines, we will explore their versatility, the technology that drives them, and the significant impact they have on local economies, food security, and culinary traditions. Join us on this journey to understand how these machines are not just transforming grains, but also reshaping the landscape of agriculture and nutrition around the globe.

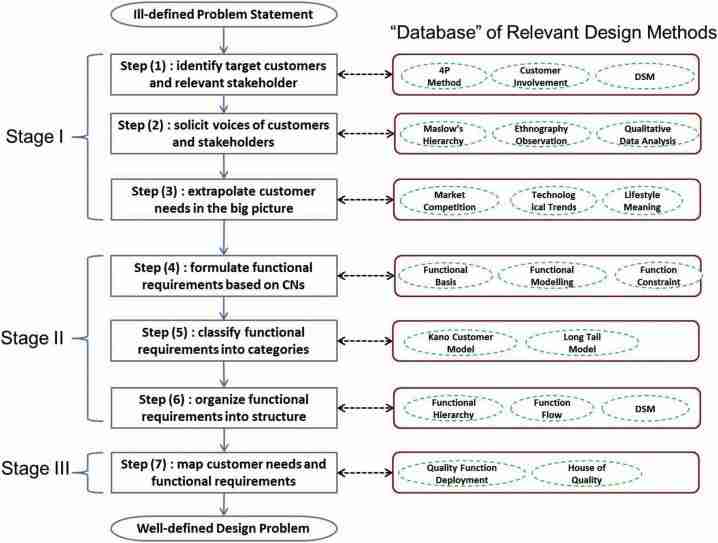

Exploring the Functional Design of Combined Rice Mill Machines

The functional design of combined rice mill machines innovatively integrates multiple processes into a single system, optimizing the rice milling journey from raw grain to edible product. By incorporating various functionalities, these machines efficiently streamline operations, significantly reducing manual labor and processing time. Key components and features include:

- Husk Removal Mechanism: A vital feature that separates the outer husk from the grain, ensuring a high yield of clean rice.

- Milling Unit: This part refines the brown rice to whitened rice, employing adjustable settings to meet different texture preferences.

- Separation Systems: Advanced screens and air currents facilitate the classification of rice by size and quality.

- Integrated Automation: Smart technology improves energy efficiency and labor savings, making the process smoother and more predictable.

Incorporating a user-friendly interface enhances operational efficiency, allowing users to monitor and customize settings effortlessly. The modular design facilitates easy maintenance and replacement of parts, prolonging the machine’s lifespan while contributing to its cost-effectiveness. Below is a summary table illustrating the advantages of combined rice mill machines:

| Feature | Benefit |

|---|---|

| Compact Design | Space-saving and easy to install |

| High Efficiency | Increased output with lower energy consumption |

| Multi-functionality | Reduces the need for multiple machines |

| Improved Quality | Consistent production of high-quality rice |

Unlocking the Benefits of Multi-Processing Capabilities

In today’s fast-paced agricultural landscape, the ability to leverage multi-processing capabilities has become a game-changer for grain transformation. Integrated rice mill machines allow producers to simultaneously perform various tasks, amplifying efficiency and productivity. By streamlining the milling processes—such as hulling, polishing, and sorting—these machines reduce the time and labor traditionally needed, leading to increased throughput and reduced operational costs. Businesses can now enjoy the synergy of combined functionalities, which ensures that grains are processed more swiftly and effectively.

Moreover, the adaptability of these advanced machines offers significant support to different processing needs, reflecting the diverse nature of grain production. With a focus on flexibility and consistency, these machines can be adjusted to deliver a variety of rice grades, appealing to a broader market. The following highlights encapsulate some key advantages:

- Enhanced Productivity: Multiple processes occur simultaneously, significantly cutting down processing time.

- Cost Efficiency: Fewer machines mean lower maintenance and operational expenses.

- Minimal Waste: Integrated systems optimize resource use and reduce spoilage.

To better understand the comparative advantages of various multi-processing machines, the table below summarizes popular models utilized in contemporary rice milling:

| Machine Model | Processing Speed (kg/h) | Key Features |

|---|---|---|

| Model A | 100 | Hulling & Polishing |

| Model B | 150 | Sorting & Packing |

| Model C | 200 | Multi-Functionality |

Maximizing Efficiency in Grain Transformation

To achieve optimal performance in grain processing, integrating high-quality combined rice mill machines is essential. These sophisticated devices streamline the overall workflow by consolidating multiple functions into a single system. Not only do they perform milling, but also hulling, polishing, and sorting, which collectively enhances throughput and reduces idle time. By utilizing these multi-functional machines, grain processors can benefit from:

- Space Efficiency: Combining operations minimizes the physical footprint of equipment needed.

- Cost Savings: Reduced labor and maintenance costs associated with operating several individual machines.

- Consistent Quality: Enhanced precision in processing leads to uniform products that satisfy market demands.

Moreover, the implementation of automated controls in these milling systems allows for precise monitoring and adjustments during the grain transformation process. This automation drastically minimizes human error and maximizes output quality. For instance, modern combined rice mill machines feature:

| Feature | Benefit |

|---|---|

| Automated Sensors | Ensure optimal milling settings based on grain type. |

| Energy-Efficient Motors | Reduce electricity costs while maintaining high performance. |

| Modular Design | Facilitates easy upgrades and maintenance. |

Sustainable Practices in Modern Rice Milling Techniques

In the ever-evolving landscape of food production, rice milling has embraced sustainable practices that not only enhance efficiency but also minimize environmental impact. Modern rice milling techniques are increasingly incorporating renewable energy sources, such as solar and biomass, to power machinery. This shift not only reduces reliance on fossil fuels but also supports rural energy autonomy. Key features of these sustainable mills include:

- Energy-efficient machinery: Machines designed to consume less energy while maintaining high output.

- Waste recycling: Utilization of husks and bran for energy generation or as organic fertilizers.

- Water-saving processes: Innovative washing techniques that significantly reduce water usage.

Moreover, the integration of smart technology in rice milling processes promotes transparency and efficiency. By implementing data analytics, mills can monitor and manage their energy consumption and resource allocation better, ultimately leading to lower operational costs and reduced carbon footprints. This digital revolution in milling also allows for enhanced quality control, ensuring that broken grains and waste are minimized. The benefits of these advancements are clear, as reflected in the following table:

| Sustainable Practice | Impact |

|---|---|

| Use of Solar Energy | Reduces energy costs by up to 30% |

| Automatic Monitoring Systems | Improves resource allocation, cutting waste by 25% |

| Water-efficient Mills | Decreases water usage by 40% |

Final Thoughts

the journey through the realm of combined rice mill machines reveals not just a technological marvel, but a transformation in the way we perceive grains. These versatile machines stand at the intersection of tradition and innovation, enabling us to unlock the full potential of rice—from paddy to polished grains. As they bridge the gap between agricultural efficiency and culinary excellence, combined rice mill machines empower farmers and entrepreneurs alike to elevate their livelihoods while catering to the ever-evolving demands of the market.

As we embrace these advancements, we are reminded of the rich tapestry of culture and sustenance that grains provide. The ability to process, refine, and innovate will continue to shape our culinary landscapes for generations to come. With each grain transformed, we not only sustain our communities but also celebrate the resilience of agriculture in a rapidly changing world. Thus, as we move forward, let us honor the versatility of combined rice mill machines—a true testament to human ingenuity and the timeless nature of our connection to food.