Transforming Harvests: The Journey of a Paddy Processing Plant

In the lush, verdant landscapes where rice paddies sway gently in the breeze, a story of transformation unfolds – one that transcends the simplicity of farming and delves into the intricate journey of paddy to plate. The journey of a paddy processing plant is not merely an industrial narrative; it is a captivating tale of innovation, sustainability, and community interwoven with tradition. As farmers cultivate their fields with age-old practices that honor the earth, the processing plant stands as a modern counterpart, bridging the gap between raw harvest and the bounty found in kitchens around the world. This article explores the multifaceted evolution of these processing facilities, unveiling the technologies that revolutionize the way we handle grain and the sustainable practices that ensure future generations can celebrate the fruits of labor. Join us as we embark on a journey through the heart of the rice industry, illuminating the path from harvest to home.

Navigating the Path from Field to Mill: Understanding the Paddy Processing Journey

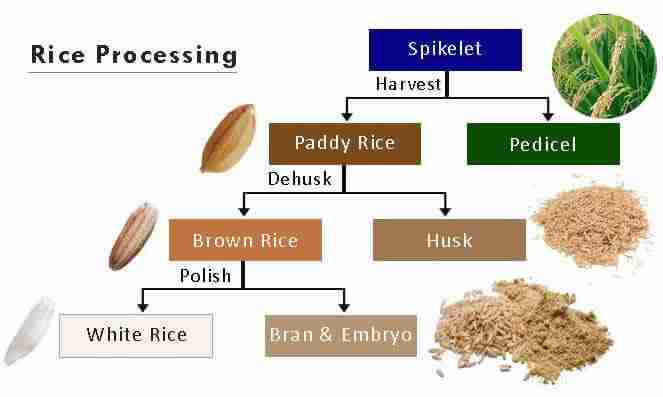

The journey of paddy from the lush green fields to the processing mill is a meticulously orchestrated process, driven by both nature and technology. Initially, the harvest involves selecting the ideal time for cutting the rice stalks, which is crucial for maximizing yield and quality. Once harvested, the rice undergoes several preliminary steps before it reaches the milling stage. The key stages include:

- Field Drying: After harvest, paddy must be allowed to dry naturally in the sun, which helps to reduce moisture content.

- Pre-Cleaning: This phase involves removing impurities like straw, dirt, and small stones through various cleaning techniques.

- Hulling: The outer husk is removed, exposing the brown rice underneath while ensuring minimal grain loss.

Once these stages are complete, the transformation toward white rice begins, marked by the milling process. This process is where technology plays a pivotal role, ensuring that each grain of rice is efficiently processed. The following steps are essential to achieving the final product:

| Milling Process Stages | Description |

|---|---|

| Grinding | The brown rice is ground to remove the bran layer, transitioning it into white rice. |

| Polishing | Rice is polished to enhance its appearance and shelf life, improving market value. |

| Sifting | Final sorting to separate broken grains and ensure uniformity. |

This transformation cycle not only emphasizes the harmony between agricultural practices and technological advancements but also highlights the importance of sustainable practices to ensure a reliable food supply. Understanding these phases helps appreciate the craftsmanship that goes into every bag of rice, turning a simple grain into a staple enjoyed worldwide.

Harvesting Quality: Key Techniques in Paddy Selection and Preparation

In the intricate dance of transforming raw paddy into the fine grains that grace our tables, the selection and preparation process becomes pivotal. It begins with a careful visual inspection of the harvested paddy, where farmers look for signs of maturity and quality. The journey continues with a thorough moisture analysis, as excess moisture can lead to spoilage. Ensuring consistency in grain size is vital, hence paddy is often subjected to sieving, where irregular grains are separated from the rest. Additionally, the practice of floating and sinking is employed, where grains are submerged in water—those that float tend to be inferior and are removed from the final selection. Each step not only enhances the final product but also guarantees that only the best grains embark on their journey through the processing plant.

Once selected, the grains are meticulously prepared for processing. Cleaning is the first major task, where impurities such as stones, dust, and unwanted grains are eradicated through a combination of air suction and mechanical sieving. Next, the paddy undergoes hulling, which removes the outer husk, transforming it into brown rice. This stage is critical as the quality of the hulling equipment directly influences the integrity of the grains. Following hulling, the rice is polished to enhance its aesthetic appeal while also safeguarding against spoilage. Below is a concise table highlighting these key techniques:

| Technique | Purpose |

|---|---|

| Visual Inspection | Assess maturity and quality |

| Moisture Analysis | Prevent spoilage |

| Sieving | Ensure consistency in grain size |

| Hulling | Remove outer husk |

| Polishing | Enhance appearance and reduce spoilage risks |

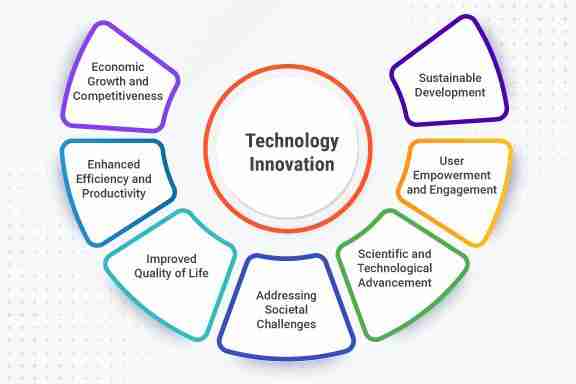

Innovative Technologies in Rice Milling: Enhancing Efficiency and Sustainability

In the realm of rice milling, cutting-edge innovations are reshaping traditional processes, seamlessly merging technology with agriculture to deliver superior results. Advanced machinery designed with automation and precision in mind significantly reduces labor costs while minimizing human error. Key technologies making waves in rice milling include:

- High-efficiency Husking Machines: These machines ensure optimal husk removal, reducing breakage and increasing yield.

- Optical Sorting Systems: Utilizing sophisticated sensors, these systems enhance grain quality by detecting and separating discolored or damaged rice.

- Energy-efficient Drying Technologies: Advanced models provide sustainable solutions that use less fuel while ensuring quicker drying times.

Moreover, the integration of data analytics presents an exciting opportunity for rice processors to track and optimize every aspect of the milling process. This not only improves productivity but also aligns with sustainable practices by minimizing waste and energy consumption. A structured overview of key benefits is shown below:

| Technology | Benefit |

|---|---|

| Automated Control Systems | Improved consistency and reduced waste |

| IoT-enabled Machinery | Real-time monitoring and maintenance alerts |

| Renewable Energy Solutions | Lower carbon footprint and operational costs |

Through the adoption of these innovative technologies, rice milling plants are not only enhancing efficiency but are also paving the way for a more sustainable agricultural future. As these systems evolve, the journey from paddy to polished grain becomes more streamlined, ensuring that every step of the process works in harmony with the growing demand for eco-friendly practices within the industry.

Sustaining Community and Environment: The Social Impact of a Paddy Processing Plant

The establishment of a paddy processing plant does more than just improve agricultural efficiency; it acts as a catalyst for community development and environmental stewardship. By providing local farmers with direct access to a reliable market for their produce, the plant empowers them economically, fostering a sense of community pride. This synergy between the plant and local farmers cultivates relationships that encourage knowledge sharing and collaboration, paving the way for sustainable practices. The plant also invests in educational programs aimed at promoting best agricultural practices, which include:

- Effective water management techniques

- Use of organic fertilizers

- Crop rotation strategies

Moreover, the plant incorporates eco-friendly technologies designed to minimize its carbon footprint. This includes energy-efficient machinery and waste-recycling systems that convert byproducts into valuable resources. By adhering to such sustainable practices, the processing facility not only reduces its environmental impact but also enhances the economic resilience of the community. An example of its contributions can be seen in the following table, which outlines initiatives implemented by the plant:

| Initiative | Description | Impact |

|---|---|---|

| Water Conservation | Installation of drip irrigation systems | Reduced water usage by 30% |

| Waste Management | Biomass recycling for energy | Cut energy costs by 20% |

| Community Workshops | Training sessions on sustainable farming | Enhanced crop yields by 15% |

Wrapping Up

As we conclude our exploration of the journey of a paddy processing plant, it’s evident that this transformation extends beyond mere equipment and facilities—it’s a narrative of resilience, innovation, and community. Each step of the process, from harvest to packaging, reflects a commitment to quality and sustainability that resonates on a larger scale. The journey of transforming raw harvests into a staple food source serves as a reminder of the intricate dance between nature and technology, tradition and modernity.

As we look toward the future, the insights gained from this revolution in paddy processing pave the way for sustainable practices that can be emulated across agricultural sectors. The plant stands as a beacon of what is possible when passion meets purpose, offering not just food but also hope for a more sustainable and secure tomorrow. In the grand tapestry of agriculture, every harvest tells a story—a story of transformation, connection, and the enduring spirit of those who work the land.