In an era where technology continues to redefine traditional practices, the agricultural sector stands on the brink of a transformative revolution. Introducing the fully automatic rice mill plant: a marvel of innovation that promises to reshape the landscape of rice production. Gone are the days of labor-intensive processes and inefficiencies that plagued the industry for so long. This advanced machinery melds precision engineering with cutting-edge automation, streamlining operations and maximizing output while significantly reducing human intervention. As we delve into the mechanics and benefits of this pioneering technology, we will explore how the fully automatic rice mill plant not only enhances productivity but also paves the way for a sustainable future in rice milling. Join us on this journey into the heart of modern agriculture, where tradition meets innovation in the quest for a more efficient tomorrow.

Innovative Technology Shaping the Future of Rice Milling

The landscape of rice milling is undergoing a remarkable transformation as state-of-the-art technology takes center stage. Fully automatic rice mill plants are at the forefront of this revolution, providing efficiency and precision that was previously unimaginable. These innovations not only enhance productivity by significantly increasing capacity but also improve the quality of the final product. Aspects such as automated sorting, grading, and packaging have been integrated into the process, minimizing human error and reducing the time from harvest to market. The seamless operation of these machines ensures that every grain is milled to perfection, maximizing both yield and profitability for millers.

Furthermore, these advanced systems incorporate smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) to monitor operations in real-time. This allows mill operators to gather critical data on performance, maintenance needs, and crop quality. By employing predictive analytics, mills can anticipate machinery failures before they occur, ensuring continuous operation. The adoption of sustainable practices is equally vital, with many setups utilizing energy-efficient designs and waste-reducing techniques that not only lower operational costs but also lessen environmental impact.

| Feature | Description |

|---|---|

| Automation | Streamlined processing from milling to packaging. |

| IOT Integration | Real-time monitoring for optimal performance. |

| Energy Efficiency | Reduced energy consumption through advanced design. |

| Quality Control | Automated grading and sorting for superior quality. |

Maximizing Efficiency: Key Features of Fully Automatic Rice Mills

In the realm of modern agriculture, fully automatic rice mills stand out for their innovative attributes that significantly enhance productivity. One of the most notable features is the real-time monitoring system, which enables operators to track various metrics such as throughput, efficiency, and machine health, ensuring optimal performance and reducing downtime. Additionally, these mills are equipped with advanced milling technology, which utilizes precision machinery to minimize grain breakage and maximize output quality. This seamless integration of technology not only streamlines the production process but also enhances the overall quality of the rice produced.

Another critical feature is the automated cleaning and sorting mechanisms, which guarantee that impurities are swiftly removed from the final product. This process not only improves the quality but also saves time and labor costs associated with manual sorting. Furthermore, fully automatic rice mills are designed with energy-efficient systems that reduce the overall energy consumption, making them environmentally friendly and cost-effective. By embracing these vital elements, rice mill operators can ensure higher yields, safe processing conditions, and, ultimately, a robust return on investment.

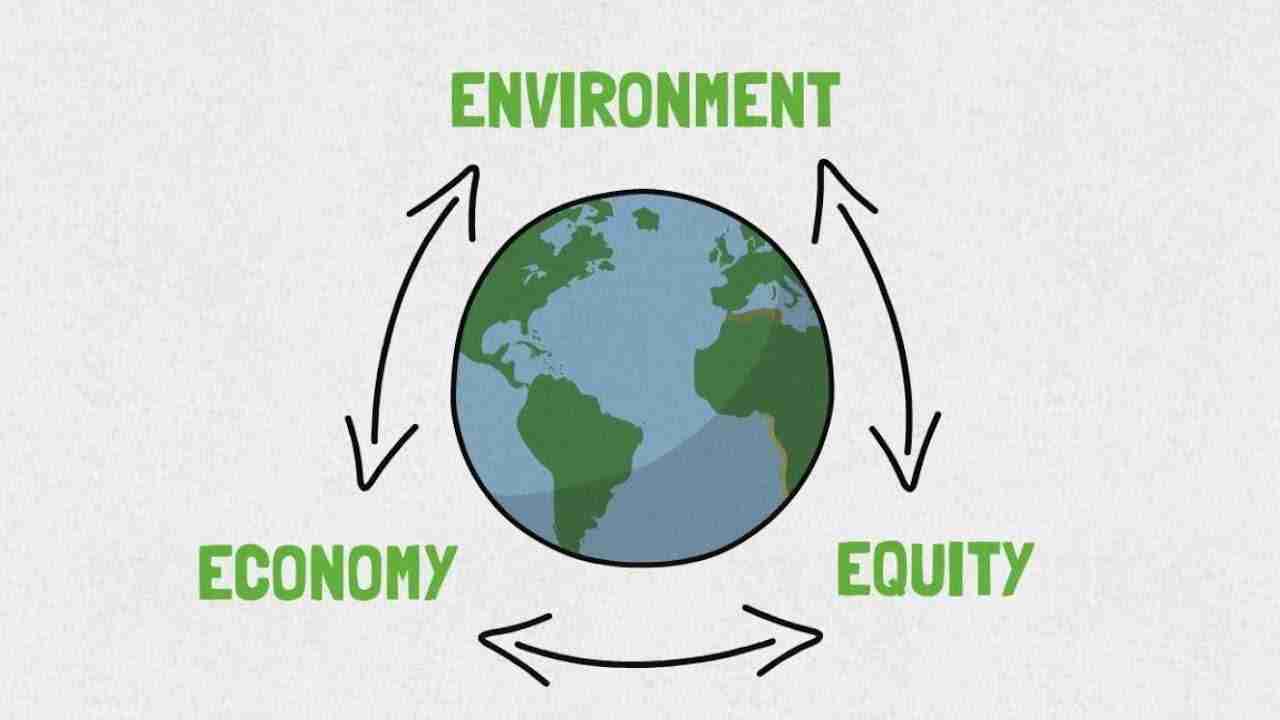

Sustainability and Environmental Impact in Rice Production

The modern rice milling industry is undergoing a profound transformation, emphasizing sustainability and minimizing environmental impact. Fully automatic rice mill plants are at the forefront of this green revolution, deploying advanced technologies that dramatically reduce energy consumption and optimize resource usage. These state-of-the-art facilities incorporate systems that recycle water and utilize solar energy, significantly lowering the carbon footprint of rice production. By integrating eco-friendly practices, such as using husk for biomass energy and converting waste into organic fertilizers, these plants foster a circular economy that benefits both the environment and local communities.

Moreover, the adoption of precision technology in rice milling enhances efficiency, leading to less waste generation and a more effective processing cycle. Key features that embody this approach include:

- Smart Monitoring Systems: Real-time data collection for improved decision-making.

- Automated Quality Control: Ensuring high-grade output without extensive manual intervention.

- Energy-efficient Machinery: Reducing power usage while maximizing output.

To showcase the remarkable impact of these innovations, the table below highlights the comparison between traditional and modern automatic rice milling processes:

| Aspect | Traditional Milling | Automatic Milling |

|---|---|---|

| Energy Consumption | High | Low |

| Water Usage | Traditional methods often waste a significant amount | Water recycling systems in place |

| Waste Generation | High, with minimal recycling | Designed for waste minimization and recycling |

Investment Considerations and Recommendations for Aspiring Mill Operators

For aspiring mill operators, diving into the realm of fully automatic rice mill plants means understanding a variety of investment considerations. Capital investment is the foremost factor to contemplate; acquiring state-of-the-art machinery may require significant upfront financing. It’s crucial to evaluate potential returns by analyzing current market trends and demand for different rice varieties. Conducting a thorough cost-benefit analysis will elucidate the financial viability of the venture, ensuring that operators are well-informed and prepared to face market fluctuations. Additionally, operators should explore financing options, such as bank loans or government grants dedicated to agricultural innovation.

Another vital aspect revolves around operational efficiency. Investing in technology that automates key processes not only enhances productivity but also reduces labor costs over time. Aspiring operators should consider the following key factors:

- Maintenance and Support: Robust after-sales service can save operators from costly downtimes.

- Energy Consumption: Evaluate energy-efficient models that contribute to lower operating expenses.

- Scalability: Choose a mill that can adapt to growing production needs as demand increases.

To facilitate a better understanding of these considerations, the following table summarizes essential features of automatic rice mills that operators should prioritize:

| Feature | Importance | Examples |

|---|---|---|

| Automation Level | Streamlines processes | Fully automatic vs. semi-automatic |

| Quality of Output | Affects customer satisfaction | Grain whiteness, broken rice ratio |

| Machine Durability | Long-term investment | Warranty periods, materials used |

Wrapping Up

the fully automatic rice mill plant stands at the forefront of agricultural innovation, embodying a transformative leap in production efficiency and quality. By integrating advanced technology into traditional practices, these systems not only promise enhanced output but also ensure that the simplicity of rice milling is preserved and refined for generations to come. As we navigate an increasingly complex global food landscape, the adoption of such progressive solutions is vital. From farmers striving for sustainability to consumers seeking consistency in their staple foods, the ripple effects of this innovation are bound to touch every corner of the rice supply chain. As we move forward, it will be fascinating to witness how the evolution of rice milling continues to shape the industry and contribute to food security worldwide. The future of rice production is indeed bright, and the fully automatic rice mill plant is leading the way.