In the realm of agriculture and food processing, where tradition meets innovation, the 5 Ton Rice Mill stands out as a modern marvel. This exceptional machine is not merely a tool for transforming harvested grains into polished rice; it is a symbol of efficiency, precision, and advancement in milling technology. As global demand for rice escalates, understanding the operational intricacies and benefits of this powerhouse becomes imperative. In this article, we will delve into the remarkable workings of the 5 Ton Rice Mill, exploring its design, functionality, and the impact it has on both productivity and sustainability. Join us as we unveil the efficiency of this engineering feat, illuminating how it serves as a cornerstone in the quest for food security and improved agricultural practices in today’s fast-paced world.

Understanding the Technology Behind the 5 Ton Rice Mill

The 5 Ton Rice Mill operates on cutting-edge technology that ensures maximum efficiency and minimal loss during the milling process. This advanced machinery integrates several essential components designed to work harmoniously, making rice processing faster and more effective. Key facets of its infrastructure are:

- Pre-Cleaning System: Removes impurities such as stones, dust, and husks before milling begins.

- Dehusking Unit: Uses rubber rolls to effectively separate the husk from the rice grain while minimizing breakage.

- Whitening and Polishing: Employs a series of abrasive stones and polished surfaces to achieve the desired whiteness and quality for the rice.

- Grading Section: Utilizes screens to classify rice grains by size, ensuring uniformity in the final product.

This mill is designed not only for productivity but also for sustainability. The integrated dust collection system captures and recycles waste materials, which can be used for fertilizer or biomass energy. A sophisticated control panel monitors the entire operation, allowing for adjustments in real-time to optimize outputs. The efficiency of the 5 Ton Rice Mill is evident in various metrics that set it apart:

| Feature | Value |

|---|---|

| Processing Capacity | 5 Tons/hour |

| Energy Consumption | Minimal |

| Waste Recovery | Up to 95% |

| Noise Level | Low |

Maximizing Productivity: Best Practices for Operation and Maintenance

To fully unlock the capabilities of the 5 Ton Rice Mill, a structured approach to operation and maintenance is essential. Establishing a routine that prioritizes preventive measures can lead to significant efficiency gains. Key practices include:

- Regular Equipment Inspections: Conducting frequent checks can help identify wear and tear, allowing for timely repairs.

- Scheduled Cleaning: Keeping the mill clean reduces contamination and maintains product quality, ultimately enhancing performance.

- Staff Training: Continuous education for operators ensures they are well-versed in the latest operational techniques and safety protocols.

Additionally, leveraging technology can optimize the operational workflow of rice milling. Implementing digital monitoring systems allows for real-time data analysis, facilitating informed decision-making on maintenance and production levels. Here’s a snapshot of common efficiency metrics:

| Metric | Ideal Value | Status |

|---|---|---|

| Capacity Utilization | 85%+ | Optimal |

| Downtime | Less than 5% | Minimal |

| Product Quality | 95% Whole Grains | Achievable |

By following these best practices, not only can the longevity of the equipment be ensured, but the overall productivity of the rice mill can also reach remarkable heights, positioning it as a leader in modern agricultural processing.

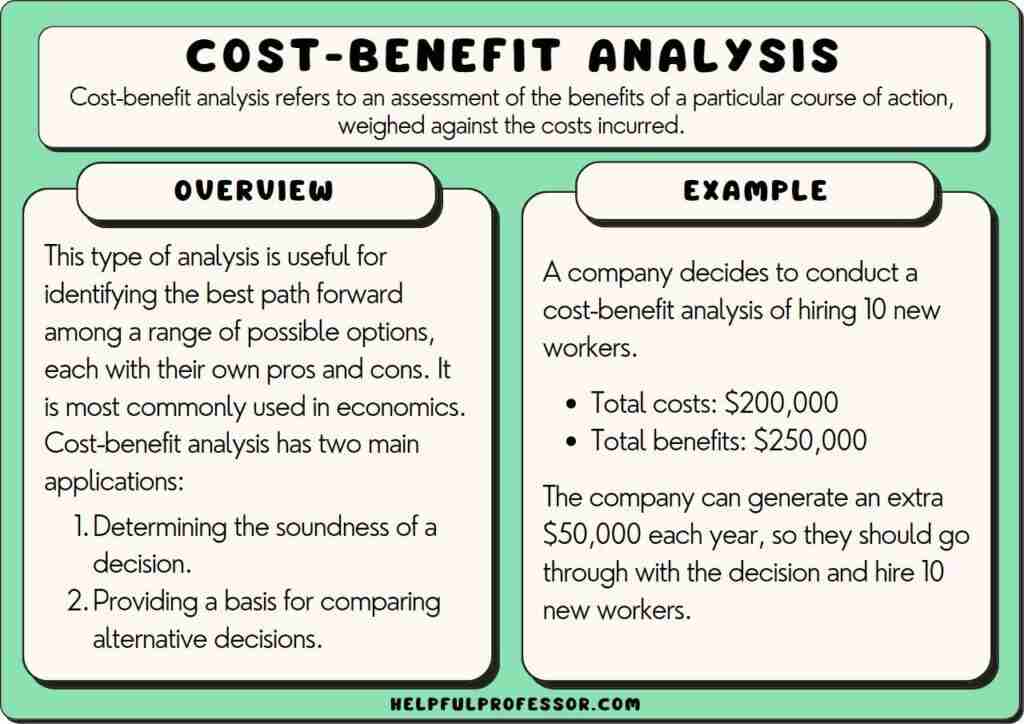

Cost-Benefit Analysis: Evaluating the Investment Potential

The decision to invest in a 5-ton rice mill hinges on a thorough understanding of its cost-benefit equation. An initial outlay is required for the acquisition of the mill, installation, and operational setup. However, this cost must be weighed against a multitude of long-term benefits that the rice mill can deliver. Potential investors should consider the following factors:

- Output Capacity: With a capacity to process 5 tons of rice daily, the mill promises a steady supply to meet market demands.

- Quality Enhancement: Modern mills employ innovative technology, resulting in higher quality rice, which can fetch better market prices.

- Labor Efficiency: Automation reduces the need for a large workforce, lowering labor costs.

- Energy Consumption: Advanced models are designed for energy efficiency, translating into reduced operational costs.

To further grasp the potential profitability, a simple comparison of projected returns versus initial investment can be enlightening. Here’s a brief overview presented in a table for clarity:

| Item | Cost (USD) | Benefit (Annual Yield) |

|---|---|---|

| Initial Investment | $50,000 | N/A |

| Annual Operational Cost | $10,000 | N/A |

| Projected Revenue | N/A | $80,000 |

| Net Profit | N/A | $20,000 |

With a calculated net profit of $20,000 annually post-expenses, the investment in a 5-ton rice mill not only becomes feasible but also promising for those looking for a steady income in agriculture. By evaluating these aspects, potential investors can make an informed decision about integrating this modern marvel into their business portfolio.

Sustainability and Environmental Impact of Modern Rice Milling Solutions

In the quest to minimize the environmental footprint of agriculture, modern rice milling solutions have made substantial strides. The 5-ton rice mill, for instance, represents a leap forward in processing efficiency while integrating sustainable practices. These machines utilize advanced technology to ensure optimal energy usage, reducing waste and emissions associated with traditional milling systems. Key features include:

- Energy Efficiency: Reduces fuel consumption by utilizing electric and energy-saving components.

- Reduced Water Usage: Innovative designs minimize water requirements for the milling process.

- Waste Management: Effective processing methods turn by-products into valuable feed or organic fertilizer.

Moreover, the environmental benefits extend beyond immediate processing efficiencies. A 5-ton rice mill contributes to sustainable farming practices through its compact design, promoting local production and reducing transport emissions. With a smaller operational footprint, these mills can be strategically placed near rice fields, encouraging community cooperation and economic growth. Here are some environmental impacts highlighted:

| Impact Area | Advantage |

|---|---|

| Energy Consumption | Lowered by up to 30% compared to traditional mills |

| Pollution Reduction | Decreased emissions from diesel-powered machines |

| Waste Utilization | Transformation of husk into bioenergy |

Key Takeaways

As we conclude our exploration into the world of the 5 ton rice mill, it becomes clear that this technological marvel is more than just a piece of machinery; it’s a transformative force within the agricultural sector. With its impressive capacity and innovative design, this modern rice mill not only enhances productivity but also promotes sustainability by optimizing resource use. As we witness the evolution of farming practices, the 5 ton rice mill stands as a testament to how technology can seamlessly blend with tradition, offering farmers a pathway to efficiency and growth. Embracing such advancements paves the way for a brighter future, where the bounty of our fields is harnessed with precision and care. the 5 ton rice mill is not just a technique for processing grains; it symbolizes the potential for agricultural innovation to rise and thrive in an ever-changing world.