In the heartland of America, where golden fields stretch as far as the eye can see, corn stands tall as one of the most versatile crops known to humankind. From the humble seed planted in spring to the vibrant tassels swaying in the summer breeze, corn goes on a remarkable journey that transforms it from field to flour. This article invites you to explore the intricate process of corn processing, highlighting the age-old traditions and modern innovations that play a crucial role in bringing this staple ingredient to our kitchens. As we peel back the layers of this fascinating transformation, we will discover not only the complexities involved but also the myriad ways corn flour enriches our diets, fuels industries, and connects us to the land. Join us as we trace the path of corn and uncover the story behind this essential grain.

The Cultivation Chronicles: Understanding the Corn Lifecycle

Every seed has a story, and for corn, that journey begins in the rich, warm embrace of fertile soil. Corn, thriving in temperate climates, germinates into vibrant green shoots that stretch toward the sun. Key stages in the lifecycle of corn include:

- Germination: The seed absorbs moisture and begins to sprout.

- Vegetative Growth: The plant develops leaves and stems, soaking in sunlight.

- Tasseling: The male flowers appear, ready to release pollen.

- Silking: The female flowers emerge, awaiting fertilization.

- Maturation: Kernels develop and ripen, signaling the end of the cycle.

As the corn approaches harvest, it transforms into golden fields, teeming with life. Farmers then embark on the journey of gathering this treasure, knowing that each ear holds the potential to create a myriad of products. The post-harvest phase involves several crucial steps, including drying, grinding, and milling corn into flour. Processing stages can be summarized as follows:

| Stage | Details |

|---|---|

| Drying | Decreases moisture content to prevent spoilage. |

| Grinding | Transforms whole kernels into fine particles. |

| Milling | Extracts flour while ensuring quality and texture. |

Harvesting Techniques: Maximizing Quality and Yield

In the pursuit of achieving optimal corn quality and yield, employing effective harvesting techniques is crucial. Timing is everything; the perfect moment to harvest typically falls when the kernels reach their maximum dry weight and the moisture level drops to around 20-25%. Tactile observation plays a significant role—farmers often check the black layer at the base of the kernel, signaling that it is ready to release its nutrients. Utilizing advanced machinery, such as combine harvesters, ensures that the grains are collected efficiently, minimizing damages that could occur if harvested by hand.

Moreover, post-harvest practices are equally vital in preserving the quality of corn. After harvesting, the kernels should be promptly removed from the field and stored properly in a controlled environment to prevent spoilage. Techniques that are commonly applied include:

- Drying: Reducing moisture content to around 13-15% to improve shelf life.

- Cleaning: Removing debris, broken kernels, and foreign materials to enhance purity.

- Storage: Utilizing silos or bins with appropriate aeration systems to maintain optimal conditions.

To illustrate the impact of timely harvesting practices on quality and yield, consider the following data:

| Harvest Timing | Average Yield (bushels/acre) | Grain Quality Rating (1-10) |

|---|---|---|

| Early Harvest | 160 | 7 |

| Optimal Harvest | 200 | 9 |

| Late Harvest | 140 | 5 |

From Kernel to Powder: The Milling Process Explained

The process of transforming corn kernels into a fine powder involves several meticulous steps, each contributing to the quality and characteristics of the final product. It begins with the careful selection of high-quality corn, where factors like moisture content and kernel integrity are assessed. The next stage involves cleaning, which is crucial. This step removes impurities, such as dirt, stones, and other foreign materials, ensuring that only the best ingredients make it to the milling stage. The cleaned kernels then undergo conditioning, where moisture is added to the corn to prepare it for milling. This helps to soften the outer shell, making it easier to separate the husk during the milling process.

Once conditioned, the kernels proceed to the milling phase, where various machines work together to grind the corn into flour. The first type of milling is often dry milling, which shatters the corn into coarse particles. It is followed by sifting, which separates larger pieces from finer flour. The resulting products include grits, corn meal, and corn flour. To guarantee consistency, multiple passes through different types of milling machines may be required. The entire process is designed to preserve the nutritional properties of the corn, aligning with the industry’s commitment to delivering a high-quality end product. Below is a quick overview of the milling process:

| Step | Description |

|---|---|

| Selection | Choosing high-quality corn based on moisture and integrity. |

| Cleaning | Removing impurities to ensure quality materials enter the process. |

| Conditioning | Adding moisture to prepare kernels for effective milling. |

| Milling | Grinding the kernels into various textures, from coarse to fine. |

| Sifting | Separating different particle sizes for product consistency. |

Sustainability in Corn Processing: Best Practices for a Greener Future

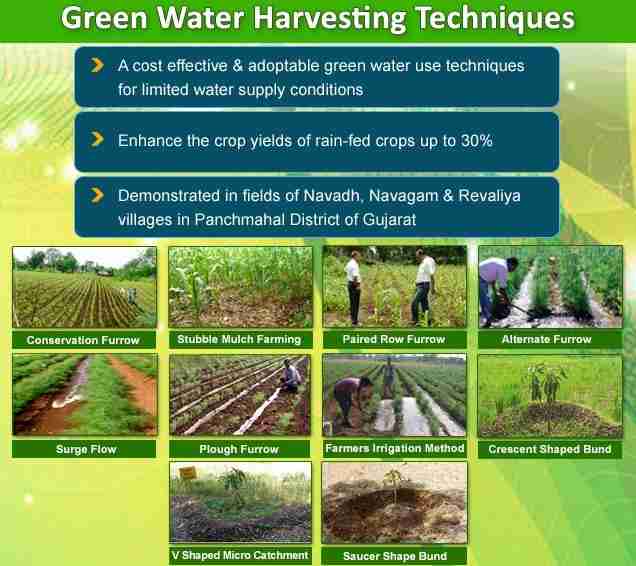

Embracing sustainable practices in corn processing is essential for fostering a healthier planet while ensuring high-quality products. One of the most effective methods begins in the field, where adopting crop rotation and no-till farming can significantly enhance soil health and reduce erosion. These methods not only improve the yield of corn but also promote biodiversity and decrease dependency on chemical fertilizers. Additionally, utilizing cover crops can mitigate nutrient runoff and improve water retention, creating a circular benefit for both the environment and agricultural viability.

As corn progresses through the processing phases, it is vital to implement energy-efficient technologies and minimize waste. This can be achieved by employing biogas systems to convert organic waste into renewable energy, which can power various stages of production. Furthermore, manufacturers can prioritize sustainable packaging options by using biodegradable materials and reducing plastic usage. Below is a simple table depicting some of these environmentally friendly practices:

| Practice | Benefit |

|---|---|

| Crop Rotation | Enhances soil fertility |

| No-Till Farming | Reduces erosion and water runoff |

| Biogas Systems | Generates renewable energy |

| Biodegradable Packaging | Minimizes plastic waste |

Wrapping Up

As we come to the end of our exploration into the journey of corn processing, it’s clear that this vibrant grain serves as more than just a staple in diets around the world. From the vast fields where it sways gently in the breeze to the humming factories where kernels are transformed into flour, corn’s journey is a testament to nature’s bounty and human ingenuity. Each step of the process—from harvesting and milling to the final product—reflects a blend of tradition and modernity, highlighting the intricate dance between agriculture and industry.

As we savor the myriad products derived from corn flour, from the comforting embrace of cornbread to the delicate texture of tortillas, let us appreciate the unseen labor that goes into bringing these delights to our tables. The story of corn is not just about the grain itself; it is about the communities, the farmers, and the millers who nurture and transform it. As we reflect on this journey, we invite you to consider the connections between the food you enjoy and the origins that make it possible. the journey of corn processing is an ongoing narrative—one that continues to evolve, reminding us of the rich tapestry of life nourished by this humble grain.