In the heart of the bustling city lies a hidden gem – a modern rice processing plant that hums with activity day in and day out. Welcome to the world of Rice Magic, where the humble grain undergoes a mesmerizing transformation from farm to table. Join us as we delve into the intricate processes and innovative technologies that bring this staple food to life in ways we never imagined.

Exploring the State-of-the-Art Machinery Used in Rice Processing

Step into the world of rice processing and witness the magic of modern machinery at work. At the heart of every rice processing plant lies a series of state-of-the-art machines that perform a variety of tasks to transform raw rice grains into the polished white rice we see on our plates. Let’s take a closer look at some of the key machinery involved in this fascinating process:

- Paddy Separator: This essential machine separates the husk from the paddy rice to prepare it for further processing.

- Whitening Machine: The whitening machine utilizes abrasive rollers to remove the remaining bran layers from the rice grains, resulting in polished white rice.

- Color Sorter: Incredibly precise cameras and sensors work together in this machine to detect and remove any discolored or defective grains, ensuring a high-quality final product.

| Machine | Function |

|---|---|

| Husker | Removes the husk from the paddy rice. |

| Polisher | Polishes the rice to give it a shiny appearance. |

| Grader | Sorts the rice into different sizes based on grain length. |

As these advanced machines work tirelessly to process tons of rice each day, it’s truly a sight to behold the precision and efficiency with which they operate. The seamless coordination between each machine ensures that every grain of rice is carefully handled and transformed into a high-quality product ready for consumption. So next time you enjoy a bowl of fluffy white rice, remember the intricate process it went through in a modern rice processing plant.

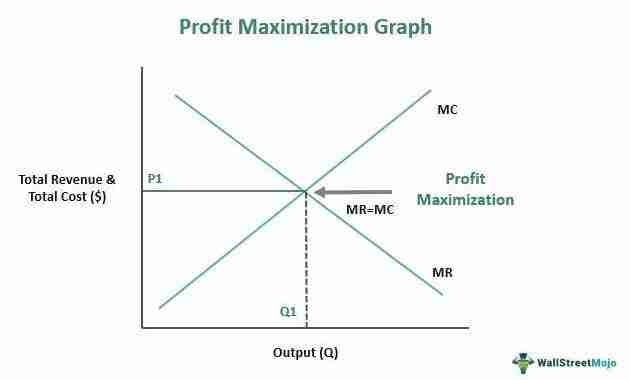

Maximizing Efficiency Through Automation and Technology

Step inside a modern rice processing plant and witness the magic of automation and technology at work. From the moment the raw rice grains enter the plant to the final packaging of the finished product, every step is optimized for efficiency. State-of-the-art machinery ensures that each grain is processed with precision and care, resulting in high-quality rice that meets the strictest standards.

Through the use of cutting-edge technology, such as automated sorting systems and computerized monitoring devices, every aspect of the rice processing plant is streamlined for maximum efficiency. Workers are able to focus on tasks that require human expertise, while machines handle the repetitive and labor-intensive processes. The result is a seamless operation that produces large quantities of rice in a fraction of the time it would take with traditional methods.

Ensuring Quality and Safety Standards in Rice Production

Rice processing plants play a crucial role in upholding quality and safety standards in rice production. These modern facilities are equipped with state-of-the-art technology to ensure that every grain of rice that reaches your table is of the highest quality.

At a modern rice processing plant, the rice goes through a series of meticulous steps to guarantee its quality and safety. These steps include cleaning to remove impurities, husking to remove the outer layer, whitening to polish the rice, and grading to sort the grains by size.

| Step | Quality Check |

|---|---|

| Cleaning | Removal of impurities such as dust and foreign particles |

| Whitening | Polishing the rice to give it a shiny appearance |

| Grading | Sorting the grains by size to ensure uniformity |

These stringent quality control measures ensure that the rice produced is not only safe for consumption but also meets the highest standards of quality. So, next time you enjoy a plate of fluffy rice, remember the magic that happens inside a modern rice processing plant!

Optimizing Sustainability Practices for a Greener Future

Step inside the doors of a modern rice processing plant and you will be amazed at the innovative sustainability practices in place. From energy-efficient machinery to water-saving techniques, these plants are leading the way towards a greener future. One of the key features of these facilities is the use of advanced technology to minimize waste and maximize efficiency. By optimizing every step of the rice production process, these plants are able to reduce their environmental footprint while still delivering top-quality products to consumers.

At the heart of these sustainability practices is a focus on resource conservation. By utilizing every part of the rice plant, from the grain itself to the husk and bran, these facilities are able to minimize waste and maximize production. Additionally, many plants have implemented recycling programs to ensure that packaging materials are used responsibly. Through these efforts, modern rice processing plants are not only providing consumers with high-quality products but also leading the way towards a more sustainable future for the industry as a whole.

The Conclusion

As we conclude our journey into the world of rice processing, we hope you have gained a newfound appreciation for the intricate and fascinating process involved in bringing this staple food to our tables. From the magical transformation of paddy into polished grains to the meticulous quality control measures in place, a modern rice processing plant truly works wonders behind the scenes. The next time you enjoy a bowl of steaming rice, remember the careful craftsmanship and dedication that goes into producing this humble grain. Thank you for joining us on this enlightening exploration of the enchanting world of rice magic.