Rice has been a staple food for centuries, nourishing populations around the globe. The revolution of rice processing has brought a wave of innovation that is reshaping how this ancient grain is cultivated and brought to our tables. From traditional hand-pounding methods to modern machinery, the advancements in rice processing are enhancing efficiency like never before. Join us as we explore how these technological breakthroughs are changing the game for rice production worldwide.

Revolutionizing Rice Processing Techniques for Increased Efficiency

Rice processing techniques have undergone a significant transformation in recent years, leading to a revolution in efficiency and productivity. By embracing innovation and technology, rice processors are streamlining their operations and maximizing output like never before.

With the introduction of advanced machinery and automation, tasks that were once labor-intensive and time-consuming are now completed with remarkable speed and precision. Additionally, the implementation of data analytics and real-time monitoring allows for better decision-making and optimization of resources. These advancements are not only increasing efficiency but also ensuring high-quality rice products that meet market demands.

Innovative Technologies Transforming the Rice Milling Industry

Technological advancements have paved the way for a significant transformation in the rice milling industry. With the introduction of innovative technologies, traditional methods of rice processing have been revolutionized, leading to enhanced efficiency and productivity. These cutting-edge solutions have streamlined the production process, ensuring higher quality output and increased yields for rice millers.

One of the key technologies driving this revolution is the adoption of automated sorting and grading systems. These state-of-the-art machines utilize advanced sensors and AI algorithms to accurately sort and grade rice grains based on size, color, and quality. This not only helps in reducing manual labor but also ensures uniformity and consistency in the final product. Additionally, the integration of IoT devices and cloud-based platforms has enabled real-time monitoring and data analytics, allowing rice millers to make informed decisions and optimize their operations for improved performance.

Maximizing Productivity and Quality Through Advanced Processing Methods

Rice processing has undergone a significant revolution with the introduction of advanced methods that aim to enhance efficiency while maximizing productivity and quality. Through the utilization of cutting-edge technology and innovative techniques, the traditional process of rice processing has been transformed into a streamlined and highly efficient operation. One of the key advancements in rice processing is the implementation of automated sorting and grading systems, which not only significantly reduces manual labor but also ensures consistency and accuracy in the final product.

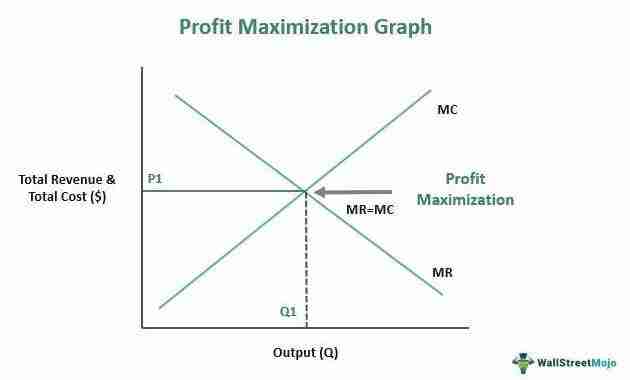

Furthermore, the integration of state-of-the-art milling equipment has enabled rice processors to achieve higher yields and superior quality rice products. With the ability to precisely control factors such as milling speed, temperature, and moisture levels, rice processors can now produce rice that meets the highest standards of quality and nutritional value. This revolution in rice processing is not only benefiting the industry by improving efficiency and productivity but also providing consumers with rice products that are of superior quality and taste.

Implementing Sustainable Practices in Rice Processing Operations

Sustainable practices in rice processing operations have become a crucial aspect of the industry, as the demand for environmentally friendly solutions continues to grow. By implementing innovative technologies and strategies, rice processing plants can significantly reduce their carbon footprint and enhance overall efficiency. One key initiative is the utilization of energy-efficient machinery, such as solar-powered dryers and biomass boilers, to minimize energy consumption and lower operating costs.

Additionally, proper waste management techniques, including recycling water for irrigation and utilizing rice husks as biofuel, can help reduce environmental impact and promote sustainability. By adopting these sustainable practices, rice processing operations can not only improve their bottom line but also contribute to a healthier planet for future generations. Together, we can revolutionize the way rice is processed and pave the way for a more sustainable future.

Concluding Remarks

In conclusion, the revolution of rice processing continues to evolve, offering new opportunities for enhancing efficiency in the industry. As technology advances and innovation thrives, we can expect to see even more improvements in the way rice is processed and distributed. By embracing these changes, we can look forward to a future where rice production is more sustainable, cost-effective, and ultimately benefits everyone involved in the process. Let’s continue to support and drive this revolution forward, ensuring a brighter future for the world of rice processing.