Nestled amidst the rolling fields of golden rice paddies lies a hidden gem of innovation – a parboiled rice processing plant. Step inside this bustling hub of activity and witness the extraordinary journey of rice from the farm to your fork. Join us on a captivating exploration of this fascinating process, where nature’s bounty is transformed into a staple of countless meals around the world. Prepare to be amazed as we unveil the secrets behind the making of parboiled rice, from start to finish.

– The Art of Parboiling: A Look at the Science Behind the Process

At a parboiled rice processing plant, the intricate dance of science and culinary artistry unfolds. The process begins with carefully selected paddy rice harvested from local farms. The paddy rice is then soaked, steamed, and dried in a series of carefully calibrated steps that enhance its nutritional profile and cooking qualities. The result is a versatile grain that retains more of its natural nutrients while offering a faster cooking time compared to regular rice.

One of the key scientific principles behind parboiling is gelatinization, where the starches in the rice are transformed into a gel-like state through the application of heat and moisture. This unique method not only improves the texture and taste of the rice but also helps in preserving its nutrients. The art of parboiling lies in striking the perfect balance between temperature, time, and pressure to achieve optimal results. With meticulous attention to detail and a deep understanding of the science behind the process, each batch of parboiled rice produced is a testament to the skill and dedication of the plant’s team of experts.

– Quality Control Measures: Ensuring Consistency and Excellence in Parboiled Rice Production

At our state-of-the-art parboiled rice processing plant, we take pride in our rigorous quality control measures that ensure consistency and excellence in every batch of rice produced. From the moment the raw paddy rice arrives at our facility to the final packaging, we maintain strict standards to guarantee the highest quality product for our customers.

Our quality control process includes meticulous testing at every stage of production, from soaking and steaming to drying and milling. We utilize cutting-edge technology and equipment to monitor key parameters such as moisture content, grain size, texture, and aroma. By adhering to these strict guidelines, we are able to deliver premium parboiled rice that meets the highest standards of taste, texture, and nutritional value.

– Sustainability in Action: How Parboiled Rice Processing Plants can Minimize Waste and Environmental Impact

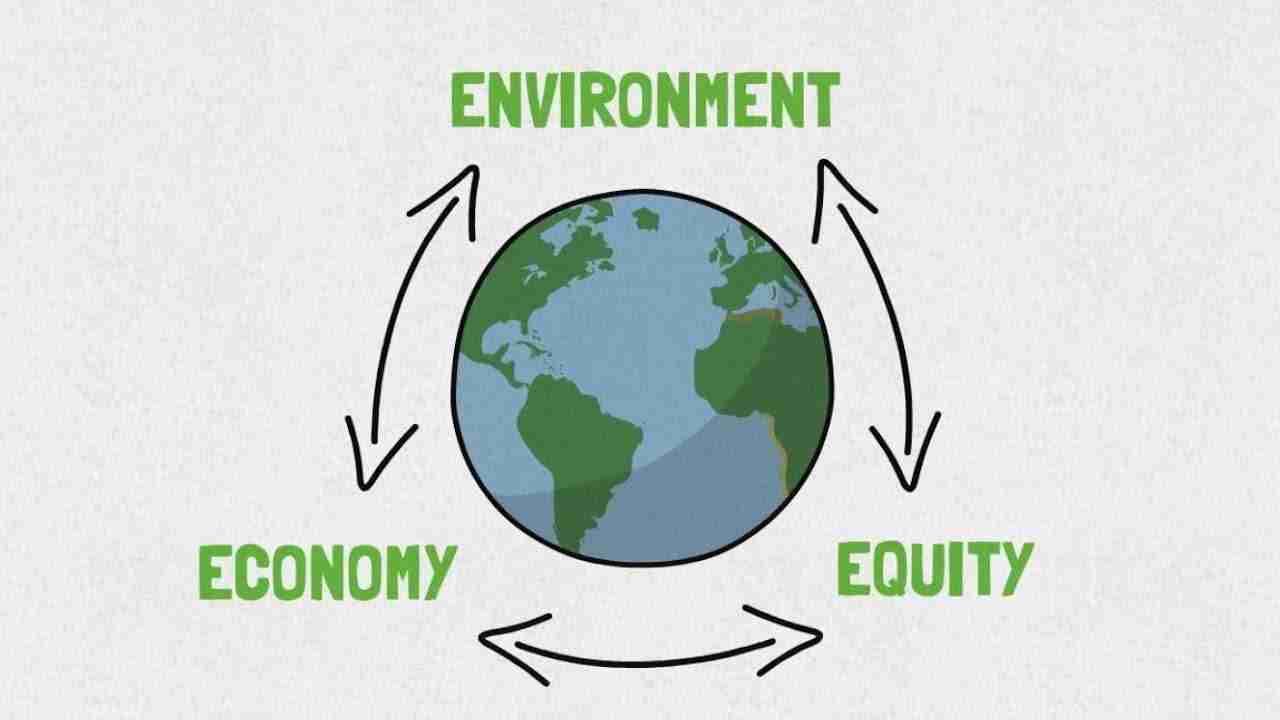

Walking through a parboiled rice processing plant is like stepping into a world where sustainability and efficiency reign supreme. From the moment the raw rice grains arrive at the facility to the final packaging of the polished product, every step is carefully designed to minimize waste and environmental impact.

One of the key ways these plants achieve sustainability is through the use of innovative technologies such as water recycling systems, energy-efficient machinery, and waste reduction programs. By reclaiming and reusing water used in the parboiling process, these plants significantly reduce their water consumption and lessen the strain on local water sources. In addition, by utilizing energy-efficient equipment and implementing waste reduction strategies, they are able to minimize their carbon footprint and overall environmental impact.

– Best Practices for Maintaining Hygiene and Food Safety Standards in a Parboiled Rice Plant

At our parboiled rice processing plant, we prioritize maintaining the highest hygiene and food safety standards throughout the entire production process. One of the best practices we follow is ensuring that all our equipment and facilities are regularly cleaned and sanitized to prevent any contamination. We have a dedicated team of trained personnel who meticulously clean and disinfect every surface to guarantee the quality and safety of our products.

Additionally, we have strict protocols in place to control pests and rodents within our facility. By implementing proper storage practices and regularly conducting inspections, we can prevent any infestations that could compromise the cleanliness of our plant. Moreover, all our employees are required to undergo thorough hygiene training to instill good practices and habits that uphold our commitment to providing safe and high-quality parboiled rice products to our customers.

Closing Remarks

As we conclude our journey through the parboiled rice processing plant, we are left with a greater appreciation for the intricate process that transforms raw grains into the staple food we enjoy on our tables. From the meticulous sorting and cleaning to the precise steaming and drying, every step is a testament to the dedication and expertise of the workers involved in bringing this product from farm to fork. Next time you sit down to savor a bowl of rice, remember the journey it took to reach your plate, and give thanks to the hands that made it all possible. Thank you for joining us on this enlightening tour of the parboiled rice processing plant. Until next time, happy eating!