In the tranquil rice paddies of Asia, a quiet revolution is taking place. The traditional methods of rice production are being upended by the ingenious innovation of automatic rice mill plants. These cutting-edge machines are changing the game, streamlining the process from harvesting to milling with unparalleled efficiency and precision. Join us as we explore the power of automatic rice mill plants in revolutionizing the age-old practice of rice production.

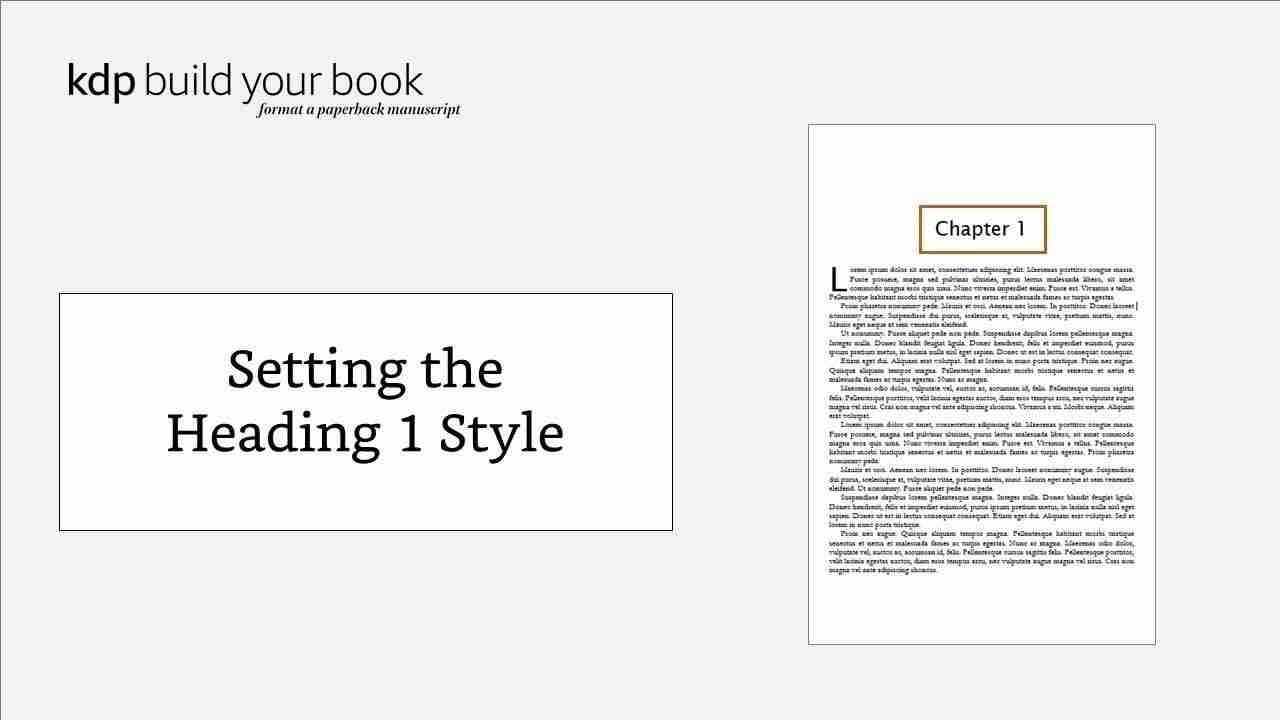

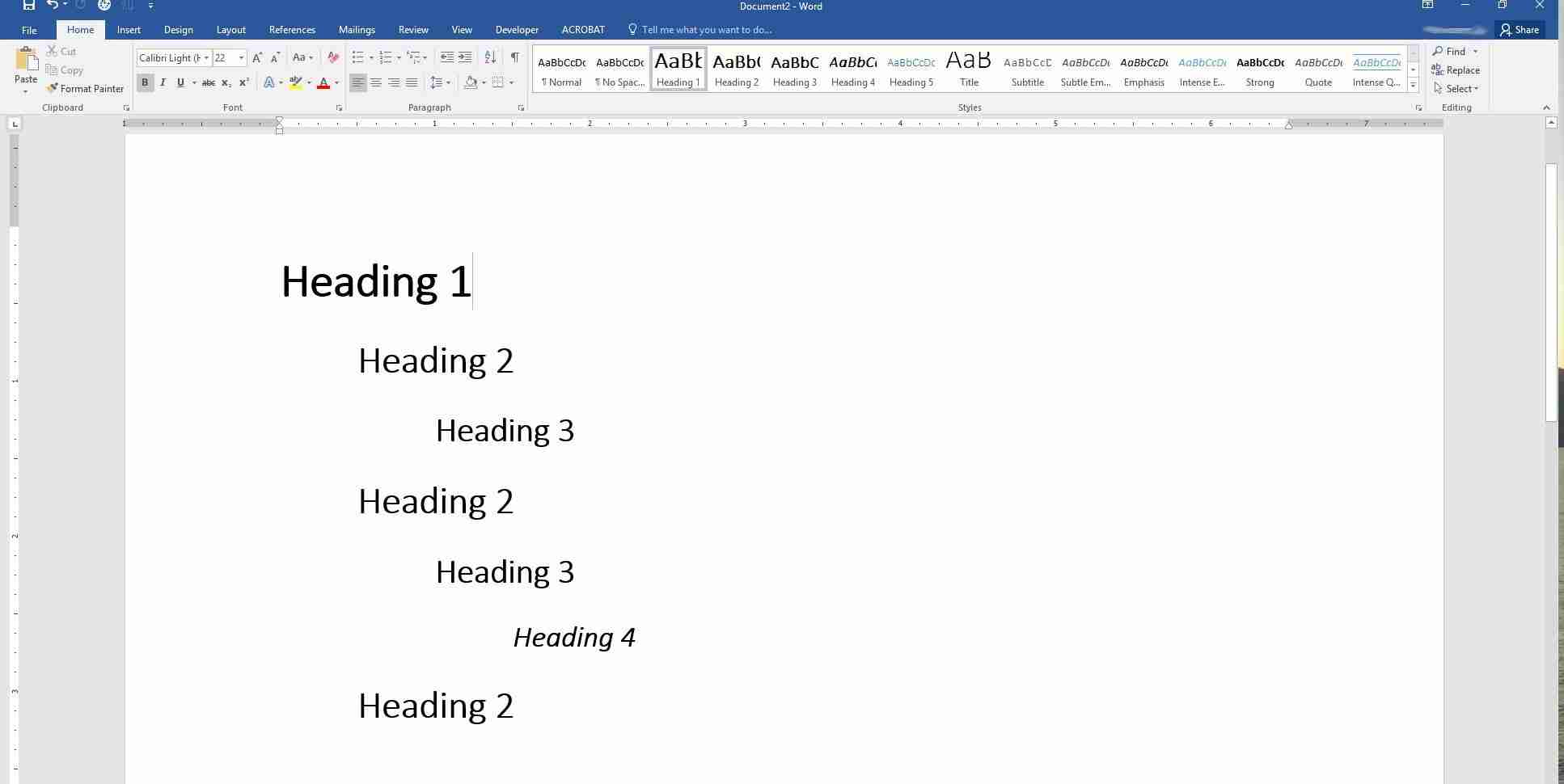

Heading 1:

Rice production has long been a labor-intensive process, with farmers spending hours manually milling their harvest. However, with the advent of automatic rice mill plants, the game has changed. These innovative machines are revolutionizing the way rice is processed, making the entire operation faster, more efficient, and more cost-effective.

One of the key benefits of automatic rice mill plants is their ability to process a large volume of rice in a short amount of time. With advanced technology and precision engineering, these machines can hull, polish, and sort rice grains with speed and accuracy. Additionally, automatic rice mill plants are equipped with features that ensure the quality and consistency of the final product, resulting in higher yields and better market value for farmers. By embracing this new technology, farmers can increase their productivity and profitability in the competitive rice industry.

Efficiency and Quality Improvement in Rice Milling Processes

Rice production has always been a vital part of agriculture, providing sustenance for millions around the world. With the advancement of technology, automatic rice mill plants have revolutionized the way rice is processed, significantly improving efficiency and quality in rice milling processes. These modern machines are equipped with cutting-edge technology to streamline the production process, from cleaning and husking to polishing and packaging.

Benefits of automatic rice mill plants include:

- Increased production capacity: These plants can process a larger quantity of rice in a shorter amount of time compared to traditional methods.

- Improved quality control: The automation of processes ensures consistency in the quality of the rice produced.

- Efficiency in operations: Manual labor is significantly reduced, leading to cost savings and increased productivity.

Heading 2:

Imagine a world where rice production is streamlined, efficient, and sustainable. With automatic rice mill plants, this vision is becoming a reality. These innovative machines are revolutionizing the way rice is processed, from milling to packaging.

Automatic rice mill plants are equipped with advanced technology that enables them to operate with minimal human intervention. They can handle large volumes of rice, ensuring consistent quality and reducing the risk of contamination. With features such as automatic sorting and grading, these plants are increasing productivity and profitability for rice producers around the world.

Cost Savings and Sustainable Practices with Automatic Rice Mill Plants

With the advancement of technology, automatic rice mill plants have been a game-changer in the rice production industry. These innovative machines not only increase efficiency but also contribute towards achieving cost savings and sustainable practices. By streamlining the process of rice milling, these plants reduce the labor required for manual intervention, leading to a significant decrease in operational costs.

Moreover, the automation of rice mill plants ensures consistent quality control, resulting in higher yields and better utilization of resources. With features such as automatic temperature control, moisture sensors, and precise milling capabilities, these plants optimize the milling process while minimizing waste. Additionally, the use of sustainable practices such as energy-efficient operations and water recycling further enhance the environmental benefits of automatic rice mill plants.

Heading 3:

Rice production has long been a labor-intensive process, requiring significant human effort to plant, harvest, and process the grain. However, with the advent of automatic rice mill plants, the industry is poised for a revolution. These state-of-the-art machines are equipped with advanced technologies that streamline the production process, ensuring higher efficiency and better quality rice.

One of the key advantages of automatic rice mill plants is their ability to reduce labor costs and increase productivity. With features such as automatic feeding, husking, and polishing, these plants can process large quantities of rice in a fraction of the time it would take traditional methods. Additionally, the precision and consistency of the machines result in a higher yield of top-quality rice, meeting the demands of consumers worldwide.

Increased Output and Enhanced Productivity for Rice Farmers

Rice farmers around the world are experiencing a revolution in their production methods with the introduction of automatic rice mill plants. These advanced technologies are changing the game for farmers by significantly increasing their output and enhancing productivity. By automating the rice milling process, farmers can streamline their operations, reduce manual labor, and improve the quality of their rice products.

With the power of automatic rice mill plants, farmers can now enjoy benefits such as:

- Increased efficiency in processing rice grains

- Consistent quality of rice products

- Higher output with less manual labor

- Improved profitability and competitiveness in the market

Heading 4:

Rice production has seen a remarkable transformation with the introduction of automatic rice mill plants. These innovative machines have revolutionized the way rice is processed, increasing efficiency, reducing labor costs, and improving overall quality. With the power of automation, rice mill plants can handle large quantities of rice with minimal human intervention, ensuring a consistent and uniform end product.

By streamlining the milling process, automatic rice mill plants can produce higher yields and minimize waste. The advanced technology used in these plants allows for precise control over the milling parameters, resulting in a higher quality product that meets industry standards. Farmers and rice mill owners alike are embracing this new technology for its ability to boost productivity and profitability in the rice industry.

Important Considerations When Implementing Automatic Rice Mill Plants

The implementation of automatic rice mill plants has the potential to revolutionize the way rice is produced, processed, and distributed. As with any major undertaking, there are a number of important considerations that need to be taken into account to ensure the success of the project. One of the key factors to consider is the size of the plant – it is important to determine the capacity of the plant based on the anticipated production volume.

Another crucial aspect to consider is the technology and machinery that will be used in the plant. It is essential to invest in high-quality equipment that is efficient, reliable, and easy to maintain. Additionally, proper training for staff members who will be operating the plant is essential to ensure smooth operation and maximize productivity. By carefully considering these factors and making informed decisions, automatic rice mill plants have the potential to greatly improve the efficiency and output of the rice production process.

Closing Remarks

In conclusion, automatic rice mill plants have undoubtedly revolutionized the way rice is produced and processed. With their efficiency, accuracy, and speed, these modern machines are changing the landscape of rice production worldwide. As we continue to embrace technological advancements in agriculture, the future of rice farming looks brighter than ever. Let us look forward to a more sustainable and productive rice industry, thanks to the power of automatic rice mill plants.