Rice, an indispensable staple in many cultures around the world, has a long history of both cultivation and consumption. From traditional hand-pounding methods to the revolutionary automatic rice mills of today, the evolution of rice production has been a fascinating journey that has transformed the way we grow and process this essential grain. Join us as we explore the automatic rice mill revolution and its impact on global rice production.

– The Historical Foundations of Rice Production

Rice production has a long and rich history, dating back thousands of years. However, one of the most significant advancements in rice production came with the invention of the automatic rice mill. This revolutionized the way rice was processed, making it faster, more efficient, and ultimately increasing production levels.

With the introduction of automatic rice mills, the traditional manual methods of processing rice were replaced by machines that could hull, polish, and sort rice at a much faster rate. This not only saved time and labor but also improved the quality of the rice produced. Farmers were now able to meet the demands of a growing population more easily, leading to an increase in rice production worldwide. The automatic rice mill revolution truly marked a turning point in the history of rice production.

– The Impact of Automation on Rice Milling

The automation of rice milling has revolutionized the way rice production is handled, leading to increased efficiency, higher quality outputs, and reduced labor costs. With the advancement of technology, automatic rice mills have become essential in streamlining the process of turning raw rice grains into market-ready products. These machines can handle various tasks such as cleaning, husking, polishing, and grading with precision and speed.

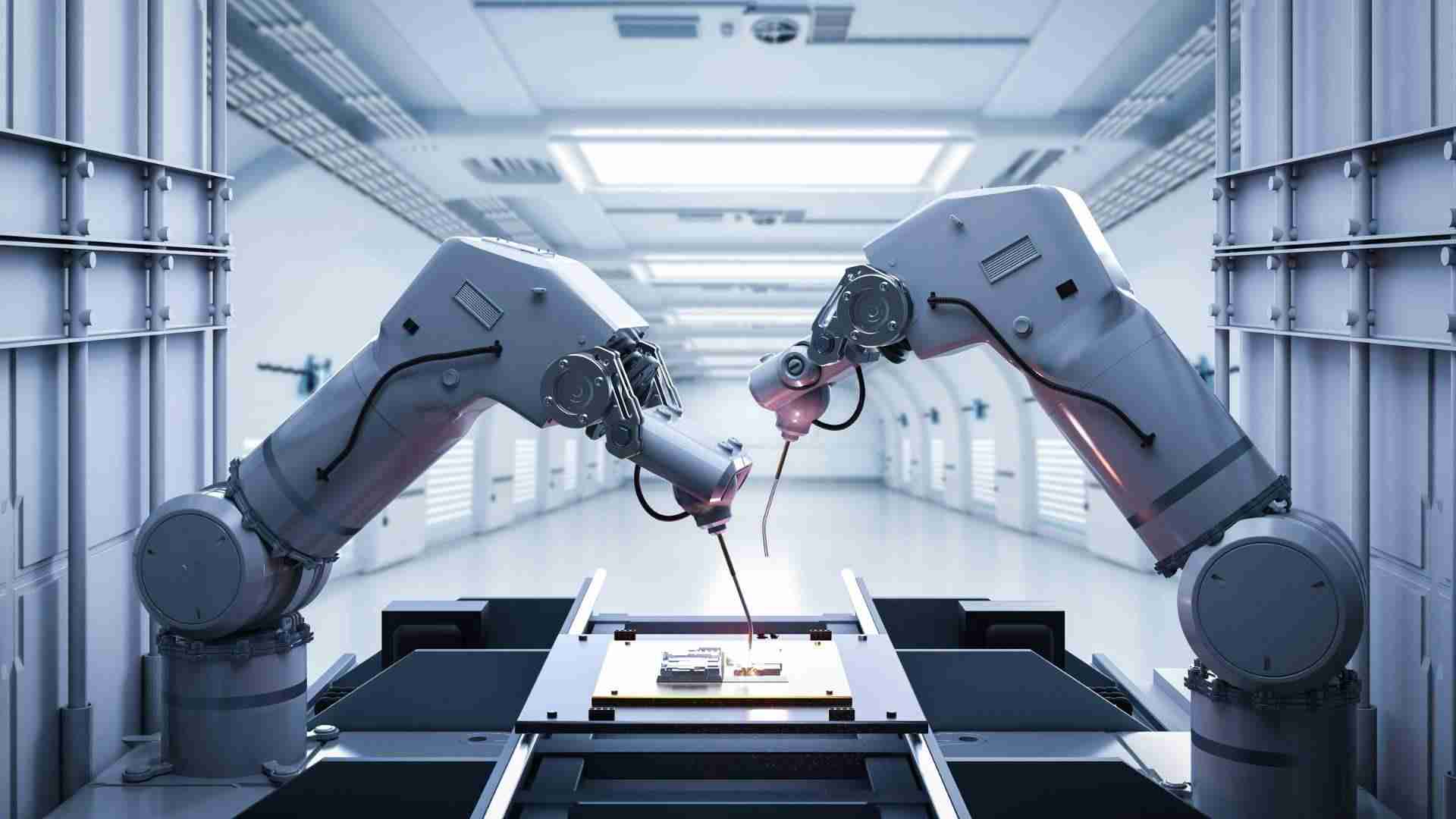

One of the significant impacts of automation in rice milling is the ability to produce consistent and uniform quality rice grains. Automated mills are equipped with sensors and control systems that ensure every batch of rice is processed to meet specific standards. This not only enhances the overall product quality but also increases the market value of the rice. Additionally, automation has resulted in a significant reduction in manual labor required for rice milling, allowing for a more efficient use of resources and increased productivity in the industry.

– Enhancing Efficiency and Quality through Automatic Technology

In recent years, the rice production industry has seen a remarkable transformation with the introduction of automatic technology. Traditional rice mills have evolved into advanced automatic rice mills, revolutionizing the way rice is processed. These modern mills are equipped with cutting-edge machinery and automated systems that enhance efficiency and quality in rice production.

With automatic technology, tasks such as sorting, cleaning, milling, and packaging are now carried out with precision and speed, resulting in higher productivity and improved quality control. The use of sensors, robotics, and artificial intelligence has enabled rice millers to optimize their processes and minimize human error. As a result, consumers can enjoy consistently high-quality rice products while rice mill operators benefit from increased profitability and reduced labor costs.

– Investing in Modern Rice Milling Equipment

Investing in modern rice milling equipment has revolutionized the way rice is produced and processed. With the advancement of technology, automatic rice mills have become the new standard in the industry. These state-of-the-art machines offer numerous benefits, from increased efficiency to higher quality output.

By incorporating modern rice milling equipment into your operations, you can streamline the production process, reduce labor costs, and improve overall productivity. The automatic rice mill revolution has brought about a significant shift in the way rice is milled, making it easier than ever to meet the demands of the market. With features such as automated grain sorting, advanced polishing techniques, and precision milling capabilities, investing in this equipment is sure to take your rice production to the next level.

Concluding Remarks

As we look back at the journey of rice production, it is clear that the introduction of automatic rice mills marked a significant turning point in the industry. The role of technology in streamlining the process, increasing efficiency, and improving quality cannot be understated. With the automatic rice mill revolution, we have witnessed a remarkable evolution that has paved the way for a more sustainable and productive future in rice production. As we continue to embrace innovation and advancements in the field, we can look forward to further improvements that will continue to shape the landscape of rice production for years to come.