In the bustling world of agriculture, where time is of the essence and efficiency is key, the automated rice mill stands as a shining example of technological innovation at its finest. With its seamless integration of advanced machinery and cutting-edge automation, this marvel of modern engineering effortlessly streamlines the rice production process, revolutionizing the way we harvest and process this essential grain. Join us as we delve into the world of the automated rice mill and discover the unparalleled efficiency it brings to the world of agriculture.

Benefits of Automating Rice Milling Operations

With the advancements in technology, automating rice milling operations has become the new standard for efficiency in the industry. One of the key is the significant increase in productivity. Automated machines are able to process larger quantities of rice in a shorter amount of time compared to manual labor, thus reducing production time and increasing output. This efficiency not only saves time but also reduces labor costs, making it a cost-effective solution for rice mill owners.

Another advantage of automating rice milling operations is the improved quality of the final product. Automated machines ensure a consistent quality of rice by minimizing human error during the milling process. By maintaining precise control over factors such as moisture levels and milling settings, automated rice mills produce rice with higher uniformity in texture and appearance. This not only enhances the overall quality of the rice but also increases customer satisfaction and market demand for the product.

Increased Production Capacity and Consistent Quality

With our state-of-the-art automated rice mill, we have been able to significantly increase our production capacity while maintaining consistent quality in every batch of rice we produce. The advanced technology integrated into our milling process ensures that each grain is processed efficiently, resulting in a higher output without compromising on quality.

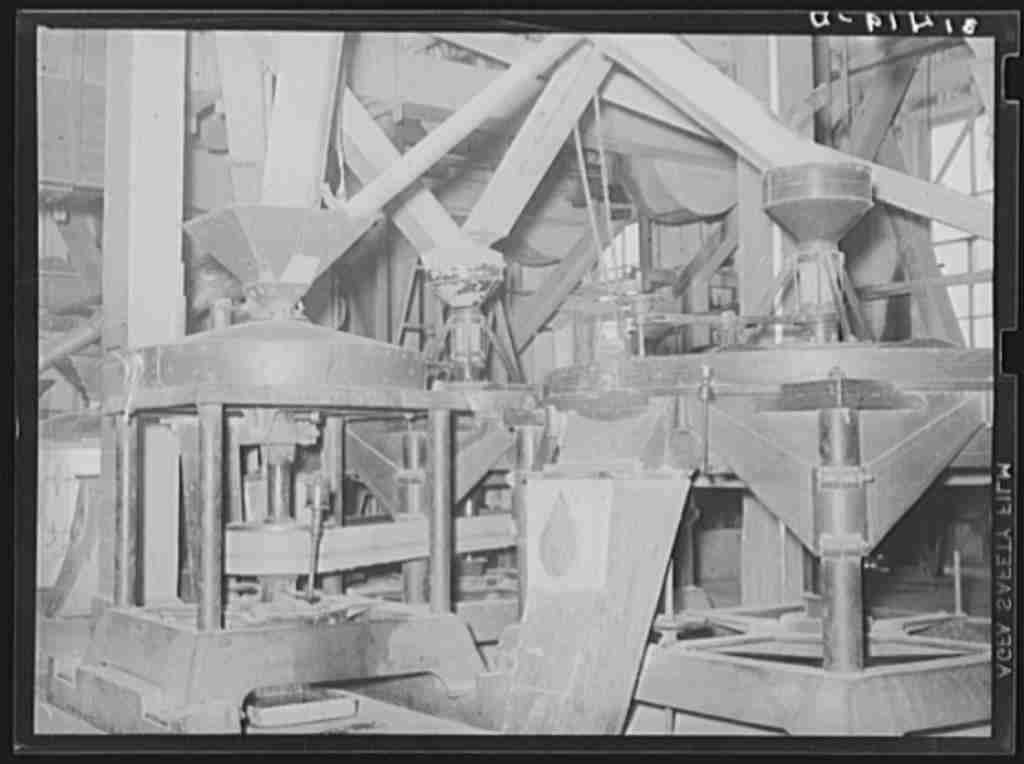

Through precise automation, our mill can perform complex tasks with ease, from cleaning and husking to polishing and sorting. This seamless process not only saves time and labor but also ensures uniformity in the texture and appearance of the final product. Our commitment to delivering top-notch rice to our customers is reflected in the meticulous attention to detail that goes into every step of our automated milling process.

Streamlined Workflow and Reduced Labor Costs

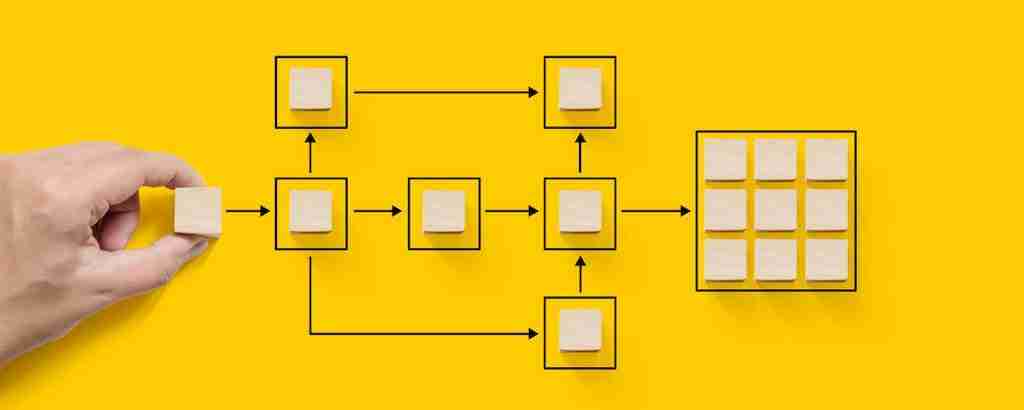

In an era where efficiency and cost-effectiveness are key priorities for businesses, automation has become a game-changer. The automated rice mill is a prime example of how streamlining workflow can lead to significant reductions in labor costs. By utilizing cutting-edge technology, this state-of-the-art facility is able to process rice at a fraction of the time and manpower required by traditional methods.

With automated systems handling tasks such as sorting, milling, and packaging, human labor is freed up to focus on more specialized roles that require creativity and critical thinking. The result is a smoother, more efficient workflow that not only saves on labor costs but also enhances overall productivity. By embracing automation, businesses can stay ahead of the curve and remain competitive in today’s fast-paced market.

Integration of Technology for Improved Efficiency and Precision

Imagine a world where every grain of rice is processed with the utmost care and precision, ensuring the highest quality product for consumers. With the integration of cutting-edge technology, this vision is no longer a distant dream but a reality. An automated rice mill represents the pinnacle of efficiency, utilizing state-of-the-art machinery to streamline the production process and eliminate human error. From cleaning and dehusking to polishing and sorting, each step is seamlessly executed with unparalleled accuracy.

One of the key benefits of an automated rice mill is its ability to significantly reduce processing time, allowing for a higher output in a shorter period. With advanced sensors and control systems in place, the mill operates with unrivaled speed and efficiency, resulting in a more cost-effective solution for rice producers. Additionally, the precision of the machinery ensures consistent quality across all batches, leading to increased customer satisfaction and brand loyalty. Embracing automation in the rice industry is not just a choice, but a necessity in today’s competitive market.

To Conclude

In conclusion, the automated rice mill stands as a testament to the perfect marriage of technology and tradition. Its seamless integration of cutting-edge automation with time-honored rice milling techniques showcases the endless possibilities when innovation meets expertise. With its effortless efficiency and precision, this modern marvel paves the way for a brighter and more sustainable future in the realm of rice production. As we look towards the horizon of progress and advancement, the automated rice mill stands as a shining beacon of possibilities yet to be explored. So let us embrace the future with open arms, knowing that the path to greatness lies in the seamless combination of tradition and technology.