In a world where food security and sustainability are increasingly paramount, the quality of staple crops like rice takes center stage in the global agricultural narrative. As one of the most widely consumed grains, rice is more than just a dietary staple; it represents livelihoods and cultures across continents. Yet, the journey from paddy fields to dining tables is complex and fraught with challenges, necessitating a keen focus on advancements in rice processing technology. “Unlocking Quality: The Future of Rice Processing Equipment” explores the innovative strides being made in this sector, delving into how cutting-edge machinery is set to enhance efficiency, preserve nutritional value, and meet the evolving demands of consumers. As we navigate the intersection of tradition and technology, this article aims to shed light on the transformative potential of modern rice processing equipment, setting the stage for a future where quality is not just an aspiration but a guarantee.

Innovative Technologies Shaping Rice Processing Efficiency

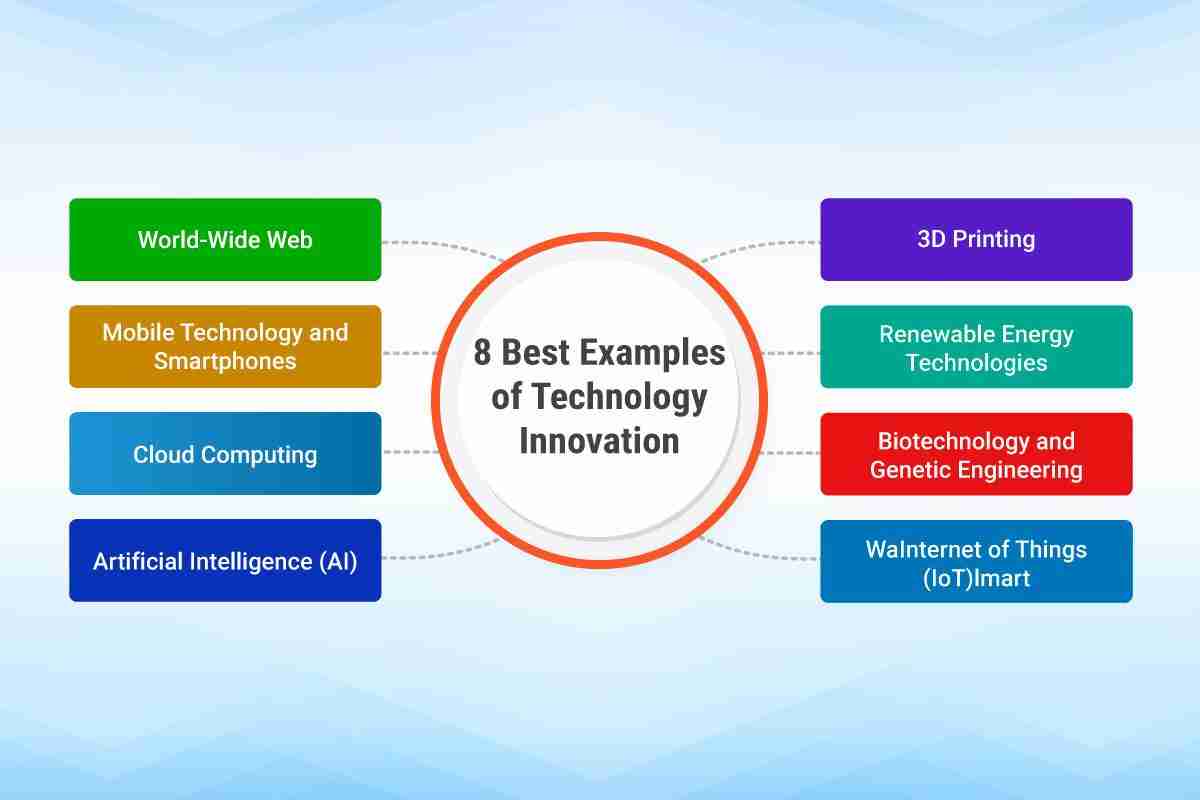

In the ever-evolving agricultural landscape, cutting-edge technologies are revolutionizing the rice processing sector, significantly enhancing efficiency and productivity. One of the standout innovations includes AI-driven sorting machines, which leverage machine learning algorithms to identify and separate high-quality grains from impurities and defects with remarkable accuracy. By minimizing human error and maximizing throughput, these machines are reshaping quality control processes. Additionally, the integration of IoT sensors in milling equipment allows for real-time monitoring of moisture levels and temperature variations, ensuring optimal storage conditions and preventing spoilage.

Furthermore, advancements in automation are simplifying labor-intensive tasks, from harvesting to packaging. Automated systems equipped with robotic arms can efficiently handle the loading, unloading, and transferring of rice products, streamlining operations and allowing staff to focus on more strategic roles. Companies are also investing in sustainable energy solutions, such as solar-powered milling facilities, reducing their carbon footprint while improving cost-effectiveness. The cumulative impact of these innovations is creating a resilient framework for rice processing that not only boosts efficiency but also enhances the overall quality of the final product.

Sustainable Practices for Eco-Friendly Rice Production

Modern rice production has a unique opportunity to blend efficiency with environmental stewardship. By implementing sustainable farming practices, producers can reduce the ecological footprint while maximizing yields. Some effective strategies include:

- Crop Rotation: Alternating rice with legumes or other crops can improve soil health and reduce pests.

- Integrated Pest Management (IPM): Utilizing beneficial insects and reducing chemical pesticide use enhances biodiversity.

- Water Management: Adopting alternate wetting and drying techniques can conserve water and reduce methane emissions.

- Organic Farming: Transitioning towards organic practices, such as the use of cover crops and natural fertilizers, promotes a healthier ecosystem.

Investment in innovative rice processing equipment plays a critical role in fostering sustainable practices. By utilizing technology that minimizes energy consumption and waste, producers can ensure that the entire production cycle is eco-friendly. Consider the following advances:

| Technology | Benefits |

|---|---|

| Solar Dryers | Reduces energy costs and carbon emissions. |

| Biomass Boilers | Generates energy from rice husks, promoting a circular economy. |

| Advanced Milling Techniques | Improves rice quality while minimizing grain loss. |

Enhancing Quality Control Through Advanced Equipment Features

“`html

Modern rice processing equipment is equipped with an array of advanced features that significantly enhance quality control in the production process. These innovations ensure that rice not only meets but exceeds industry standards. Some key features include:

- Real-time Monitoring Systems: Continuous data collection allows operators to track quality parameters, making immediate adjustments as needed.

- Automated Sorting Technology: Machine learning algorithms identify and separate defective grains, minimizing waste while maximizing product quality.

- Precision Milling Controls: Advanced sensors regulate milling intensity, preserving grain integrity and nutritional value.

The integration of these sophisticated features creates a robust framework for quality assurance. For instance, many modern machines feature:

| Feature | Benefit |

|---|---|

| Moisture Control Sensors | Ensure optimal moisture levels, preventing spoilage and enhancing shelf life. |

| Dust and Grain Separators | Remove impurities, ensuring a cleaner product and maintaining consumer trust. |

| User-Friendly Interfaces | Reduce operator error, facilitating easier handling and improved operational efficiency. |

“`

Future Trends in Automation and Smart Processing Solutions

The landscape of rice processing is rapidly evolving, driven by advancements in automation and smart technology. As the demand for higher quality and greater efficiency intensifies, manufacturers are embracing the synergy of intelligent systems and machine learning. State-of-the-art equipment now incorporates features such as real-time monitoring and predictive maintenance, minimizing downtime and enhancing productivity. These innovations not only streamline production flows but also elevate product integrity by ensuring consistency and precision in every batch.

In this transformative atmosphere, several emerging trends stand out:

- IoT Integration: Smart sensors and IoT-enabled systems are revolutionizing data collection and analysis, allowing processors to make informed decisions swiftly.

- Automation: Fully automated rice mills are becoming the norm, reducing labor costs and improving operational efficiency.

- Machine Learning Algorithms: These algorithms can optimize processing parameters based on environmental conditions and input variations, leading to significant quality enhancements.

In addition to automation, sustainability is taking the center stage. Innovative rice processing equipment now minimizes energy consumption and waste, aligning with global green initiatives. An overview of these advancements is depicted in the table below:

| Advancement | Key Benefit |

|---|---|

| Smart Sensors | Improved quality control |

| Automated Systems | Reduced labor costs |

| Energy-efficient Machinery | Lower operational costs |

Insights and Conclusions

As we stand on the precipice of innovation in rice processing, the future gleams with promise. The advancements in technology and machinery not only enhance the efficiency and precision of rice production but also uphold the fundamental values of quality and sustainability. By embracing these new techniques, producers can ensure that every grain tells a story of care, innovation, and dedication to the craft.

As we unlock the potential of tomorrow’s rice processing equipment, we invite stakeholders across the industry to join us in this journey. The commitment to elevate our practices not only secures the livelihood of farmers but also enriches the plates of consumers worldwide. Together, let us cultivate a future where quality reigns supreme, ensuring that rice continues to be a staple that nourishes the world for generations to come. The grains of today are the seeds of tomorrow’s promise—let’s cultivate them wisely.