Transforming Rice: Inside the Heart of a Processing Plant

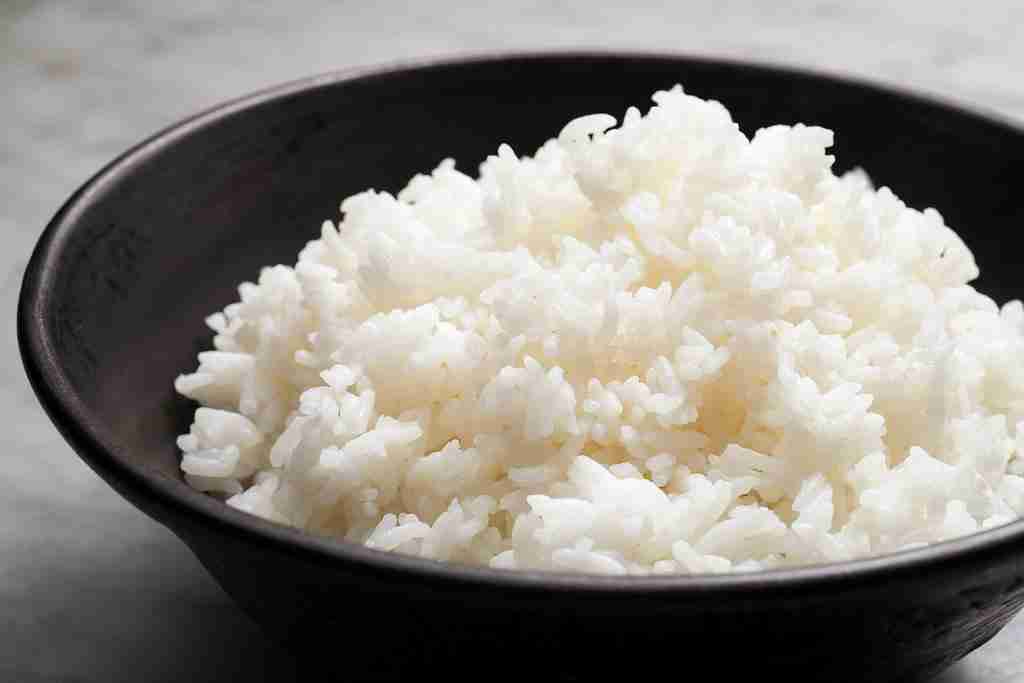

As the golden grains of rice sway gently in the breeze under the sunlit sky, an intricate journey awaits them, one that begins far from the serene paddies where they are harvested. Rice, a staple food for billions across the globe, undergoes a fascinating transformation that elevates it from humble grains to culinary essentials. Hidden behind the walls of processing plants—sleek, buzzing hubs of activity—this metamorphosis unfolds, blending age-old traditions with modern technology. In this article, we venture beyond the surface, delving into the heart of a rice processing plant. We’ll explore the meticulous steps that bring us the rice on our plates, from cleaning and milling to packaging and distribution, revealing the dedication and innovation that ensure quality and sustainability in every grain. Join us as we unveil the extraordinary processes that make rice not just a food, but a vital connection to cultures and communities around the world.

The Journey of Rice: From Paddy to Processed Perfection

In the intricate world of rice processing, the transformation begins at the paddy fields, where the grains glisten under the sun, nurtured by water and earth. Once harvested, the raw rice makes its way to the processing plant, a bustling hub where machinery and human expertise converge to breathe life into these humble grains. The journey entails several critical stages, each designed to enhance the quality and flavor of the rice. Key processes include:

- Drying: Reducing moisture to prevent spoilage.

- Hulling: Removing the outer shell to reveal the brown rice.

- Milling: Polishing the grain to achieve that classic white rice appearance.

- Grading: Sorting the rice based on size and quality.

The heart of the processing plant is a symphony of mechanical precision and human touch. Workers meticulously oversee each stage, ensuring that the grains maintain their nutritional integrity and pristine flavor profile. The use of technology enhances efficiency, allowing real-time adjustments to keep production smooth. Table 1 illustrates the percentages of rice that progress through various processing stages, showcasing just how much effort goes into producing that perfect bowl of rice.

| Processing Stage | Percentage of Rice |

|---|---|

| Harvesting | 100% |

| Drying | 95% |

| Hulling | 90% |

| Milling | 85% |

| Grading | 80% |

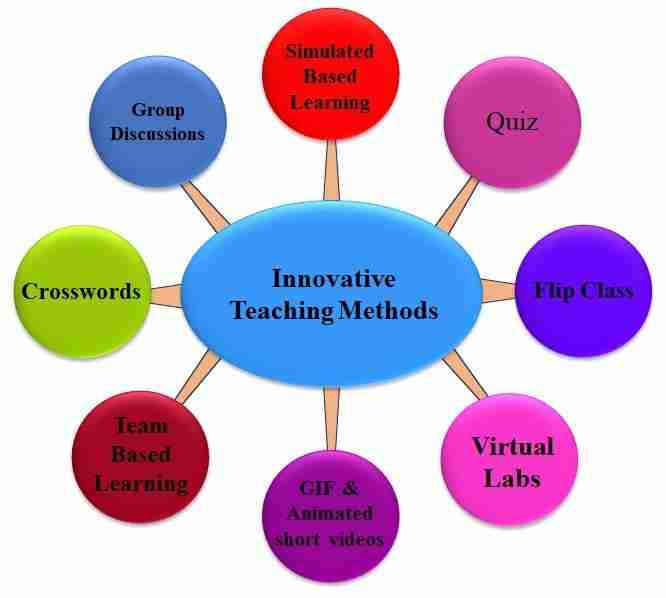

Innovative Techniques: Enhancing Quality through Modern Technology

In the quest for superior rice quality, modern processing plants are embracing a plethora of innovative techniques that harness cutting-edge technology. One of the most notable advancements is the integration of automation and AI-driven systems, which streamline the entire production process. These technologies not only enhance efficiency but also significantly reduce human error, ensuring that every grain of rice meets stringent quality standards. Key innovations include:

- Automated Sorting Machines: These machines utilize advanced imaging technologies to assess grain quality and remove impurities with unparalleled precision.

- Moisture Control Sensors: Continuous monitoring of humidity levels in storage silos ensures optimal conditions for rice preservation.

- Traceability Systems: Blockchain technology enables complete tracking of rice from field to consumer, enhancing transparency and trust.

Beyond machinery, processing plants are increasingly using data analytics to refine their operations. By collecting and analyzing data at every stage, from harvesting to packaging, plants can identify patterns and areas for improvement. This results in optimized processes that not only save resources but also improve the overall flavor and nutritional content of the rice. A simple comparison of traditional versus modern techniques illustrates the transformative impact:

| Technique | Traditional Approach | Modern Approach |

|---|---|---|

| Quality Control | Manual inspection | AI-driven automated sorting |

| Storage Management | Periodic checks | Real-time monitoring |

| Production Insights | Experience-based | Data analytics driven |

Sustainability in Action: Eco-Friendly Practices within Processing Plants

In the quest for a greener future, processing plants are stepping up by implementing eco-friendly practices that not only enhance efficiency but also reduce their environmental footprint. Innovative waste management strategies are becoming commonplace, allowing facilities to convert by-products into valuable resources. For instance, rice husks, typically discarded, are now being transformed into biofuel, thereby contributing to energy self-sufficiency. This practice not only minimizes waste but also supports the circular economy by creating a sustainable source of energy for the plant’s operations.

Furthermore, water conservation remains a critical component of sustainability in these facilities. Advanced filtration systems are being employed to recycle water used during the production process, reducing the overall demand on local water resources. Alongside this, the integration of solar panels and energy-efficient machinery is playing a significant role in cutting down carbon emissions. The commitment to sustainability is reflected in various initiatives, including:

- Implementing dust control measures to improve air quality.

- Using biodegradable packaging to reduce plastic waste.

- Training staff on eco-conscious operations.

- Engaging with local communities to promote sustainable farming practices.

Maximizing Efficiency: Streamlining Operations for Optimal Output

In a rice processing plant, efficiency is crucial at every stage, from intake to packaging. By leveraging advanced technology and innovative practices, facilities can streamline operations, significantly enhancing productivity. Key strategies include:

- Automated Sorting and Grading: Utilizing high-tech machinery to ensure consistent quality while reducing manual labor.

- Real-time Data Analytics: Implementing systems that track and analyze operational data, enabling quick adjustments to avoid downtimes.

- Lean Manufacturing Principles: Adopting practices that minimize waste and maximize resourcefulness, ensuring smoother workflows.

Moreover, optimizing the layout of equipment and workflows can yield substantial improvements in operational efficiency. This can be maintained through regular training sessions for staff, which fosters a culture of continuous enhancement. A few pivotal elements to consider include:

| Key Elements | Benefits |

|---|---|

| Equipment Maintenance | Prevents breakdowns and prolongs machinery lifespan |

| Cross-Training Employees | Enhances flexibility in workforce deployment |

| Inventory Management | Reduces excess stock and optimizes resource allocation |

Key Takeaways

As we draw our exploration of rice processing to a close, it becomes evident that the journey from paddy fields to polished grain is a mesmerizing blend of tradition, technology, and teamwork. Behind every grain lies the diligent efforts of countless individuals working in harmony, converting raw harvests into the staple we depend on every day.

The processing plant, with its rhythmic machinery and meticulous attention to detail, stands as a testament to human ingenuity and adaptability. It is here that the humble rice undergoes its remarkable transformation, emerging not just as food, but as a cultural cornerstone and a vital element of sustenance across the globe.

With innovations continually redefining the landscape, the future of rice processing promises even greater efficiency and sustainability. As consumers, we gain a deeper appreciation for our food and the intricate systems that support it. We invite you to reflect on the significance of this journey every time you savor a bowl of rice, understanding that it is so much more than just a meal – it is a story of resilience, respect for the land, and the relentless pursuit of excellence.

Thank you for joining us in this exploration inside the heart of a processing plant. Until next time, may your meals be nourishing, and your understanding of their origins, profound.