In the world of agriculture, few staples hold as significant a place as rice, nourishing billions and shaping culinary traditions across the globe. Yet, behind the delightful simplicity of a steaming bowl of rice lies a complex journey—one that begins long before the grains hit our tables. Central to this transformation is the intricate machinery that processes rice, turning it from a rough-hewn product of nature into the polished grain we know and love. In this article, we will delve into the fascinating realm of rice processing equipment, exploring the technology and craftsmanship that play pivotal roles in refining this essential crop. Join us as we uncover the steps, innovations, and machinery that bring grains to life, illustrating how efficiency and precision redefine the way we experience one of the world’s most cherished foods.

Exploring the Evolution of Rice Processing Techniques

Rice processing techniques have undergone remarkable advancements, reflecting the dynamic needs and technological innovations of each era. From ancient methods that employed simple hand tools to contemporary machinery that maximizes efficiency and quality, this evolution is a testament to human ingenuity. Early rice processing involved manual labor and rudimentary equipment like mortar and pestle for hulling, while modern techniques leverage automatic rice mills, which dramatically reduce labor intensity and increase yield. These state-of-the-art machines can precisely control parameters like moisture content and milling duration, enabling producers to achieve high-quality rice that meets the demands of consumers around the globe.

The transformation in processing techniques is not just about machinery; it also encompasses a broader understanding of post-harvest technology. Some notable aspects include:

- Improved Efficiency: Modern rice millers can process large quantities of paddy in a fraction of the time it took with older methods.

- Quality Control: Advanced machinery is equipped with sensors and automated systems that ensure the consistency and quality of the final product.

- Environmental Considerations: New processes are designed to reduce waste and energy consumption, reflecting a growing commitment to sustainability.

| Era | Technique | Equipment |

|---|---|---|

| Ancient | Hulling by Hand | Mortar and Pestle |

| Medieval | Water-powered Mills | Millstones |

| Modern | Automated Milling | Rice Processing Machines |

Understanding the Essential Equipment for Rice Milling

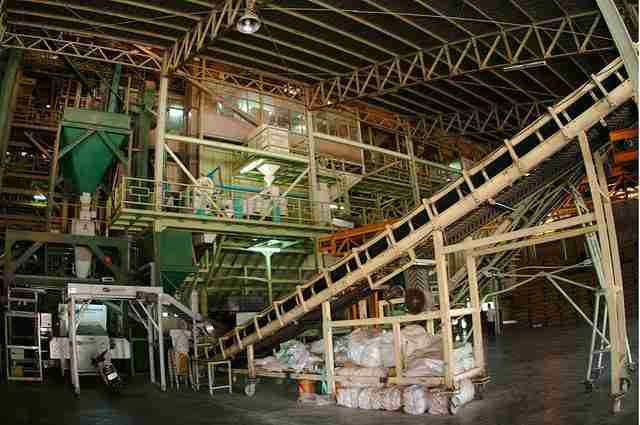

Rice milling is a meticulous process that requires a variety of equipment to ensure efficiency and quality. Among the most vital machines is the rice huller, which is designed to remove the outer husk from the paddy. This initial step is crucial as it prepares the grains for subsequent processes. Following this, the milling machine takes center stage. It is responsible for transforming the hulled rice into white rice by removing the bran and germ layers. These stages are complemented by color sorting machines, which sift through the processed rice to eliminate any discolored grains or foreign materials, ensuring the final product meets quality standards.

Moreover, other essential tools play significant roles throughout the milling operation. The rice washer is utilized to clean pre-milled grains, removing any remaining dirt or impurities before they undergo milling, while dryers control moisture levels, preventing spoilage. Incorporating a packaging machine at the end of the line allows for efficient and secure packing of the finished product. Here’s a brief overview of key equipment:

| Equipment | Function |

|---|---|

| Rice Huller | Removes the outer husk from paddy |

| Milling Machine | Processes hulled rice into white rice |

| Color Sorting Machine | Eliminates discolored grains and impurities |

| Rice Washer | Cleans grains before milling |

| Dryer | Controls moisture levels to prevent spoilage |

| Packaging Machine | Packages the final product securely |

Optimizing Efficiency: Best Practices in Rice Processing

Increasing the efficiency of rice processing involves several key factors that contribute to both the quality of the final product and the overall productivity of the operation. Implementing advanced technology is crucial; high-performance equipment can reduce waste and enhance throughput. Investing in automated systems, such as automated weighers and sorting machines, not only streamlines the process but also minimizes human error. Additional strategies include:

- Regular Maintenance: Consistent upkeep of machinery ensures optimal performance and longevity.

- Training Workforce: Educating staff on equipment operation and troubleshooting can lead to substantial efficiency gains.

- Quality Control Measures: Implementing rigorous quality checks at each stage reduces rework and waste.

A comprehensive layout design can dramatically enhance workflow within the rice processing facility. Proper arrangement of processing equipment can minimize movement, ensuring that materials transition smoothly from one stage to another. To illustrate these best practices, consider the following table showcasing key processing stages along with recommended equipment:

| Processing Stage | Recommended Equipment |

|---|---|

| Cleaning | Vibrating Screen |

| Hull Removal | Hullers |

| Polishing | Rice Polishers |

| Packing | Automatic Bagging Systems |

By focusing on these factors, rice processing operations can not only achieve optimal results but also position themselves for future growth in a competitive market. Staying informed of industry innovations and adopting best practices will ultimately pave the way for sustained efficiency and effectiveness in rice processing.

Innovative Trends and Future Directions in Grain Transformation

The landscape of grain transformation is rapidly evolving, driven by technological advancements and a growing emphasis on sustainability. Equipment designed for rice processing is at the forefront of these innovative changes, showcasing enhancements that streamline operations while minimizing waste. High-efficiency milling machines, for example, are now equipped with intelligent control systems that adjust settings in real-time, reducing energy consumption and improving grain quality. Integration of AI and IoT technologies is also revolutionizing monitoring and maintenance, enabling predictive analytics that can anticipate machinery needs and prevent breakdowns before they occur.

Moreover, sustainability is becoming a primary focus in the rice processing sector. Innovative technologies such as water-efficient parboiling equipment and biomass-based energy systems are paving the way for cleaner, more eco-conscious processing methods. The implementation of waste-to-value approaches, where by-products of rice milling are transformed into animal feed or biofuel, is gaining traction. This not only contributes to a circular economy but also enhances the overall profitability of rice processing enterprises. Here’s a snapshot of some key technologies shaping the future:

| Technology | Benefits |

|---|---|

| Smart Milling Systems | Real-time adjustments & energy savings |

| Water-efficient Parboiling | Reduced water usage & higher quality |

| Biomass Energy Production | Utilizes by-products for energy |

| IoT Monitoring Tools | Predictive maintenance & operational efficiency |

In Conclusion

As we conclude our exploration into the world of rice processing equipment, it becomes evident that the transformation of grains is both an art and a science. The journey from paddy fields to polished grains involves a complex interplay of technology and tradition, each step meticulously designed to enhance quality while ensuring efficiency. Whether it’s through innovative milling techniques or advanced sorting mechanisms, the equipment used in this vital industry plays a pivotal role in meeting global food demands and sustaining livelihoods.

As we leave the machinery behind, let us embrace the larger narrative of food security and sustainability that rice processing embodies. This intricate process not only feeds billions but also preserves cultural heritage and supports rural economies. In a world where rice remains a staple for so many, the continuing evolution of rice processing equipment signifies a commitment to nurturing this essential grain in a rapidly changing landscape.

Thank you for joining us on this insightful journey. As advancements in technology propel the rice industry forward, we remain curious to witness how these innovations will further transform our relationship with one of humanity’s most cherished staples. Until next time, may we appreciate every grain on our plate and the dedicated efforts that bring it there.