In the heart of agricultural innovation lies a staple that has nourished civilizations for centuries: rice. As global demand for this versatile grain continues to soar, the methods by which it is processed are undergoing a dramatic transformation. Enter the realm of modern rice processing equipment—a fusion of technology and tradition designed to enhance efficiency and sustainability in rice production. From sophisticated milling techniques to automated sorting and packaging systems, the latest advancements are reshaping the landscape of rice processing, promising to meet the needs of an ever-growing population. This article delves into the cutting-edge technologies making waves in the industry, exploring how they unlock new levels of productivity while preserving the quality and integrity of one of the world’s most beloved foods. Join us as we uncover the innovations that are setting the stage for a more efficient and sustainable future in rice processing.

Innovative Technologies Shaping Modern Rice Processing

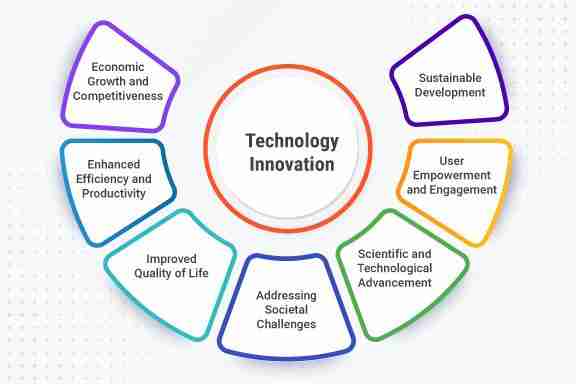

The landscape of rice processing has been revolutionized by a wave of innovative technologies, enhancing both efficiency and quality. One of the most significant advancements is the integration of automated sorting systems powered by artificial intelligence. These systems utilize machine learning algorithms to identify and separate grains based on size, color, and quality, ensuring a more precise selection. Additionally, smart sensors embedded in processing equipment monitor parameters such as moisture content and grain temperature in real-time, allowing for immediate adjustments to optimize output. This data-driven approach not only elevates the quality of the rice but also minimizes waste, making the entire processing cycle more sustainable.

Furthermore, energy-efficient machinery is making strides in reducing the carbon footprint associated with rice processing. Advanced steam and drying technologies are designed to consume less energy while maximizing output, contributing to both cost savings and environmental sustainability. The emergence of robotic automation in packaging and handling processes further streamlines operations, allowing for greater scalability and reduced labor costs. The combination of these cutting-edge advancements is transforming rice milling facilities into smart operations, pushing the boundaries of what is possible in agricultural processing.

Enhancing Sustainability through Advanced Machinery Solutions

In the realm of rice processing, the convergence of advanced machinery and sustainable practices is unlocking new pathways to efficiency and environmental stewardship. The integration of energy-efficient technologies in rice mills not only reduces power consumption but also lowers carbon footprints significantly. This means that mill operators can now produce higher yields while minimizing waste. Key features of modern equipment include:

- Automated sorting systems that reduce losses and ensure quality

- Energy recovery systems that utilize byproducts for powering machinery

- Eco-friendly coatings that enhance the durability of equipment

Moreover, the adoption of precision agriculture technologies, paired with sophisticated machinery, offers a holistic approach to rice production. These innovations allow farmers to monitor crop health and soil conditions more accurately, leading to optimized resource use. The following table summarizes the impact of these advanced solutions on sustainability:

| Feature | Benefit |

|---|---|

| Automated Sorting | Higher yield with minimized crop loss |

| Energy Recovery | Reduced operational costs and emissions |

| Precision Monitoring | Optimized input usage for healthier crops |

This comprehensive embrace of technology not only augments productivity but also ensures that rice processing contributes positively to the environment, paving the way for sustainable agricultural practices that can benefit generations to come.

Maximizing Yield Quality: Key Features of New Equipment

Innovations in rice processing equipment have significantly transformed the landscape of yield quality enhancement. Modern machinery is now engineered to prioritize precision and efficiency, allowing for the meticulous separation of high-quality grains while minimizing breakage and waste. Key features that contribute to this advancement include:

- Advanced Sorting Technology: Utilizes optical sensors and image processing to identify and sort grains based on size, color, and defects.

- Multi-Stage Milling Systems: Incorporates progressive milling methods that reduce the potential for grain damage through controlled pressure and temperature settings.

- Automated Quality Control: Employs real-time data analytics that monitor and adjust processing parameters to ensure consistent product quality.

Moreover, cutting-edge features promote sustainability alongside quality improvement. Equipment designed with energy efficiency in mind not only reduces operational costs but also lessens the environmental impact of rice processing. Notable innovations include:

- Eco-Friendly Materials: Development of machinery made from recyclable and energy-efficient components for reduced carbon footprint.

- Water Conservation Systems: Integrated technologies that minimize water usage during rinsing and soaking processes.

- Waste Recovery Solutions: Systems that capture and repurpose by-products, turning what was once waste into valuable resources.

| Feature | Benefit |

|---|---|

| Precision Milling | Enhanced grain integrity and reduced breakage. |

| Automated Quality Checks | Consistent output quality with minimal human error. |

| Energy Efficiency | Lower operational costs and reduced environmental impact. |

Best Practices for Implementing Efficient Processing Systems

To maximize the benefits of modern rice processing equipment, organizations should focus on integrating advanced technologies seamlessly into their existing workflows. This involves assessing your current operations to identify areas where automation can significantly enhance productivity. Consider the following strategies:

- Invest in Training: Provide comprehensive training programs for staff to ensure they can operate new machines effectively.

- Regular Maintenance: Schedule routine maintenance to prevent breakdowns and prolong the lifespan of equipment.

- Data Analytics: Utilize data-driven insights to optimize operational efficiency and make informed decisions regarding process adjustments.

- Feedback Loop: Establish a feedback system where operators can report issues and suggest improvements, fostering a culture of continuous enhancement.

Another essential aspect of efficiency lies in the layout and design of the processing facility. Optimizing floor plans can minimize transportation time and reduce delays. Take into account the following design considerations:

| Design Element | Description |

|---|---|

| Workflow Layout | Design the layout to facilitate a logical flow of materials and personnel. |

| Accessible Workstations | Create workstations that allow operators easy access to necessary tools and equipment. |

| Safety Zones | Incorporate safety zones to protect workers and ensure compliance with regulations. |

The Way Forward

the journey through the advancements in rice processing equipment reveals a landscape brimming with innovation and opportunity. As we explore these cutting-edge technologies, from precision milling to automated sorting, it’s clear that the future of rice processing is not only about enhancing efficiency but also about ensuring sustainability and quality.

As the demand for rice continues to grow, these technological advances provide a pathway for producers to meet this challenge head-on. By embracing modern machinery, stakeholders in the rice industry can optimize their operations, reduce waste, and deliver a superior product to consumers worldwide.

As we bid farewell to the traditional methods that have long shaped this industry, the dawn of high-tech solutions invites rice processors to reimagine their practices. The potential for improved productivity and profitability stands as a testament to human ingenuity and the relentless pursuit of progress.

So, as we look towards the horizon, let us continue to unlock the keys to efficiency and elevate the rice processing industry into a new era of excellence. The grains of tomorrow are ripe for transformation, and with every innovative step forward, we cultivate not just better processes but a more sustainable and prosperous future for all.