Introduction: Unveiling the Grain of Excellence in Rice Milling

In the world of culinary delights, few staples hold as much significance as rice. Revered across cultures for its versatility and nutritional value, rice is more than just a side dish; it’s the heart of countless meals that bring families together. However, the foundation of a great rice experience begins long before it reaches your plate. Enter the rice mill—a crucial ingredient in the journey from paddy to pantry. With an array of options available, choosing the right rice mill can be a daunting task, whether you’re a home cook, a restaurant owner, or a farmer looking to scale your production.

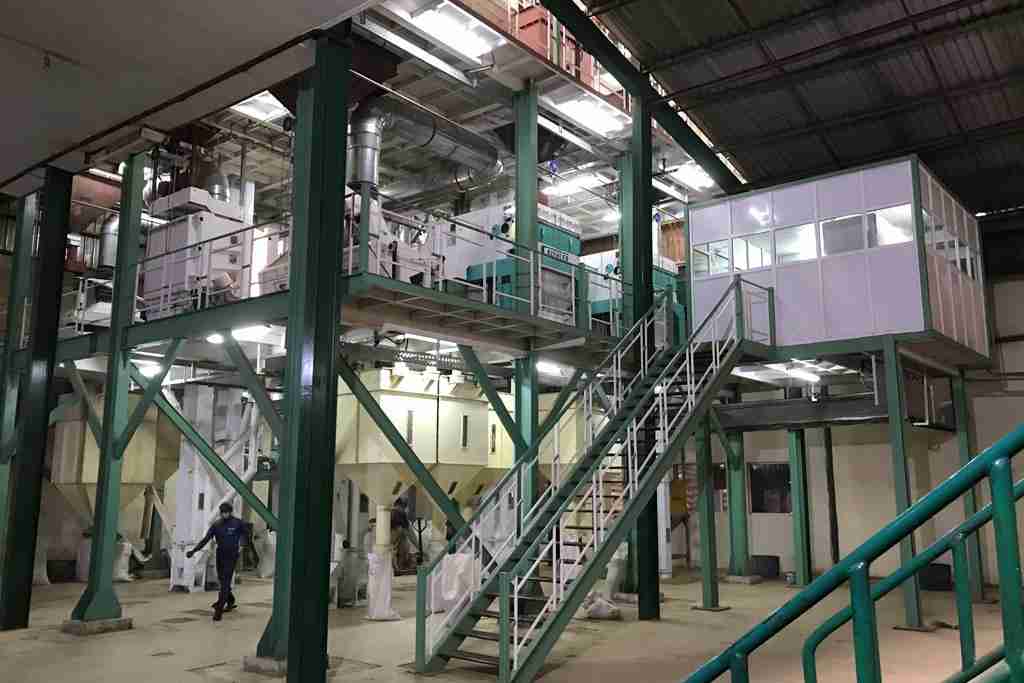

In this comprehensive guide, we will explore the top choices for the best rice mills on the market, analyzing their features, benefits, and suitability for various needs. We aim to demystify the milling process, shedding light on how the right equipment can transform raw grains into culinary perfection. From robust industrial models designed for large-scale operations to compact, user-friendly machines perfect for home use, our detailed insights will equip you with the knowledge needed to make an informed decision. Join us as we navigate the world of rice milling, ensuring that every bowl of rice you serve is as delicious as it is well-crafted.

Choosing the Right Type of Rice Mill for Your Needs

When selecting a rice mill, it’s important to consider the specific needs of your operation. Small-scale farmers often benefit from portable, compact models that offer convenience and functionality without requiring a significant investment. These mills are designed to handle limited quantities, making them perfect for those who engage in small farming or milling on a family scale. In contrast, large-scale operations may need more robust, industrial-grade mills capable of processing larger volumes of rice efficiently. These machines not only enhance productivity but also feature advanced technologies to ensure minimal grain loss and superior product quality.

To make an informed decision, you should also evaluate the following factors:

- Capacity: Choose a mill that can meet your production demands.

- Durability: Look for models made from high-quality materials that will withstand rigorous use.

- Maintenance: Opt for mills with easy-to-access parts and minimal upkeep requirements.

- Cost-effectiveness: Consider both the initial investment and long-term operating costs.

For those looking to compare different types of rice mills, the following table outlines key features of various models:

| Rice Mill Type | Best For | Key Features |

|---|---|---|

| Compact Mill | Small Farmers | Portable, Cost-effective, Easy to use |

| Commercial Mill | Large Operations | High Capacity, Automated, Industrial-grade materials |

| Multi-functional Mill | Versatile Users | Multiple grain processing, Adjustable settings |

By taking the time to assess these factors and features, you’ll be better equipped to choose the right rice mill that aligns with your needs, ensuring a smoother and more effective milling process tailored to your agricultural ambitions.

Key Features to Consider When Selecting a Rice Mill

When selecting a rice mill, it’s essential to evaluate several critical aspects to ensure you choose the right machine for your needs. First, consider the capacity of the mill. This refers to the amount of rice it can process in a given time frame. A higher capacity mill is ideal for larger operations or commercial use, while smaller mills may suffice for personal or small-scale needs. Additionally, look into the energy efficiency of the mill; opting for machines that consume less power not only reduces operating costs but also minimizes environmental impact.

Another significant factor is the quality of milling. Make sure the rice mill can produce high-quality rice with minimal broken grains. Features like adjustable milling settings can enhance the final product’s texture and appearance. Don’t overlook the maintenance requirements; some mills are designed for easy cleaning and servicing, which translates to less downtime. Lastly, consider the support and warranty options. Reliable customer support and a robust warranty can provide peace of mind, ensuring that any issues can be resolved quickly and effectively.

| Feature | Importance |

|---|---|

| Capacity | Determines efficiency and speed based on scale. |

| Energy Efficiency | Reduces operational costs and environmental footprint. |

| Quality of Milling | Affects the texture and marketability of the rice. |

| Maintenance Requirements | Impacts uptime and ongoing operational costs. |

| Support & Warranty | Ensures quick resolution of issues for sustained operations. |

Top Brands and Models in the Rice Mill Market

The rice mill market is brimming with various brands and models that cater to different processing needs, making it essential for buyers to assess their options carefully. Among the industry leaders, Husqvarna, Nihon Shokken, and Satake are well-regarded for their innovative designs and reliability. These brands offer a range of features, from traditional stone milling to modern automated systems, ensuring that processors can achieve maximum efficiency and quality. Popular models, such as the Satake STG Series and Nihon Shokken SRI-600, stand out for their energy efficiency and compact design, ideal for small and medium enterprises looking to optimize production without sacrificing space.

Alongside these giants, several other brands like Lalitha and Bühler are gaining traction for their user-friendly designs and advanced technology integration. These manufacturers focus on sustainability and reduced waste, which resonates with modern consumers’ eco-conscious values. When considering a rice mill purchase, factors such as grain processing capacity, energy consumption, and maintenance are critical. Here’s a quick comparison of some top models that highlight their strengths:

| Brand | Model | Processing Capacity (kg/hour) | Power Consumption (kW) |

|---|---|---|---|

| Husqvarna | HM-RM910 | 800 | 5 |

| Nihon Shokken | SRI-600 | 600 | 4 |

| Satake | STG-Series | 1000 | 6 |

| Lalitha | LRM-15 | 500 | 3.5 |

Maintenance Tips for Longevity and Optimal Performance

Maintaining your rice mill is essential not only for its longevity but also for ensuring it operates at peak performance. To achieve this, start with regular cleaning of the mill components, especially those that handle grains directly. Dust and residue build-up can lead to inefficiencies and can even impact the quality of the rice processed. Ensure that you’re routinely checking and replacing filters, as clogged filters can significantly strain the motor and reduce overall productivity. Implement a weekly maintenance checklist to keep track of these tasks.

In addition to cleaning, it’s vital to monitor the mechanical parts for wear and tear. Regularly inspect the blades, belts, and gears for any signs of damage or wear. Address any issues promptly to avoid costly repairs down the line. Keeping your rice mill properly lubricated is another crucial step; it reduces friction and prolongs the lifespan of moving components. Consider maintaining an organized log of repairs and upgrades, as this can help you identify patterns or recurring issues that may need professional attention.

Insights and Conclusions

selecting the right rice mill can significantly enhance your milling experience, whether you’re a small-scale farmer or an established food producer. The options presented in this guide reflect a blend of innovation, efficiency, and user-friendly design tailored to suit diverse needs and preferences. As you explore these top choices, consider not only the technical specifications and features but also your unique requirements and budget.

Remember, investing in a quality rice mill can lead to improved yield and better quality output, ultimately impacting the success of your business or household. We encourage you to weigh the pros and cons of each option, seek feedback from fellow users, and envision how these machines can fit into your workflow.

As the industry evolves, staying informed about the latest advancements will further aid in making the most informed decision. We hope this comprehensive guide has equipped you with valuable insights to navigate the world of rice milling and find the perfect fit for your needs. Here’s to a future of high-quality rice production, enhanced by the right tools at your disposal!