In the lush green fields where rice paddies sway gently in the breeze, a silent revolution is taking root beneath the surface. As the sun rises over the horizon, illuminating the diligent farmers who faithfully tend to their crops, a wave of innovation is transforming the traditional practices of rice harvesting and processing. Gone are the days when labor-intensive methods dominated the landscape; today, state-of-the-art paddy processing machines are stepping into the limelight, redefining how this staple food is harvested, milled, and prepared for markets across the globe. This article delves into the heart of this transformation, exploring the latest advancements in paddy processing technology, their impact on efficiency and sustainability, and the promise they hold for the future of food security. Join us as we uncover the interplay between tradition and innovation, where the age-old art of rice cultivation meets the dynamic forces of modern engineering.

Exploring the Latest Technology in Paddy Processing Machines

html

The evolution of technology in paddy processing has seen remarkable advancements that streamline the entire harvesting process. Modern machinery now incorporates smart technology, which enhances efficiency and reduces waste. Farmers are adopting systems that employ AI algorithms, enabling precise adjustments during processing to maximize yield. This leap in innovation not only improves quality but also makes sustainability a priority. Some key features of new paddy processing machines include:

- Automatic sorting: Using advanced sensors to separate high-quality grains from defects.

- Energy-efficient designs: Machines that consume less power while delivering higher output.

- Modular systems: Allowing for easy upgrades and maintenance.

Moreover, the integration of IoT (Internet of Things) has enabled unprecedented connectivity. Farmers can monitor the processing conditions remotely, ensuring that each grain receives the care it requires. Below is a table highlighting some innovative paddy processing machines and their unique features:

Machine Model

Unique Feature

Processing Capacity (kg/hr)

EcoPaddy 3000

Energy-efficient motor

1000

SmartSort Pro

Automated grain sorter

800

HarvestMax 500

Modular design

1200

Maximizing Efficiency: The Impact of Automation on Harvest Handling

In the world of agricultural production, efficiency is paramount, and the integration of automation technology into harvest handling is revolutionizing this sector. Advanced paddy processing machines minimize manual labor while maximizing output through streamlined operations. By utilizing machine learning algorithms and IoT connectivity, these machines can monitor and analyze crop conditions in real-time, allowing for precise timing in harvesting and processing. This not only speeds up the operation but also ensures that the crops maintain high quality, reducing wastage and increasing profitability.

Some key benefits of automated harvest handling systems include:

- Increased Speed: Automation reduces the time between harvesting and processing, maintaining the freshness of the grain.

- Precision: Technological advancements allow for accurate sorting and grading, ensuring only the best quality rice reaches consumers.

- Labor Efficiency: Fewer workers are needed, which helps farms save on labor costs and reduces the risk of injuries associated with manual harvesting.

- Scalability: Automated systems can be scaled according to the size of the farm, supporting both small and large operations effectively.

| Feature | Benefits |

|---|---|

| Real-time Monitoring | Enhanced decision-making for optimal harvesting times. |

| Automated Sorting | Consistent quality control and efficient processing. |

| Data Analytics | Insights to improve future crop yield and management. |

Sustainability in Agriculture: Eco-Friendly Innovations in Paddy Processing

In the realm of agricultural practices, innovations in paddy processing machines are paving the way for eco-friendly solutions that significantly reduce environmental impact. These advanced technologies focus on minimizing resource consumption, while maximizing efficiency. By employing solar energy, bio-based fuels, and water recycling systems, these machines not only streamline the paddy processing workflow but also actively contribute to sustainable farming practices. Moreover, these enhancements help to lower greenhouse gas emissions and decrease the carbon footprint associated with conventional methods.

Among the notable innovations are machines equipped with smart sensors and automated controls that optimize the drying process, ensuring precise moisture content while reducing energy use. Other eco-friendly advancements include:

- Biodegradable materials for construction and components, replacing plastics.

- Air filtration systems that minimize dust and improve air quality.

- Modular designs that allow for easier maintenance and upgrades, extending the lifespan of machinery.

These innovations not only support the environment but also empower farmers, making sustainable practices a viable option for future harvests. The integration of such eco-friendly technologies marks a significant step towards a more environmentally conscious method of paddy processing, transforming the agricultural landscape.

Enhancing Quality: Techniques for Improving Rice Milling Outcomes

Achieving optimal quality in rice milling requires not only advanced machinery but also a series of techniques that can significantly enhance the overall process. Modern paddy processing machines are equipped with features that focus on precision and efficiency, allowing for better control over various stages of milling. Techniques such as temperature control and moisture management play a pivotal role. Maintaining the ideal temperature while processing helps in preserving the rice’s natural flavors and nutritional content, while ensuring the correct moisture level is crucial for preventing breakage during milling.

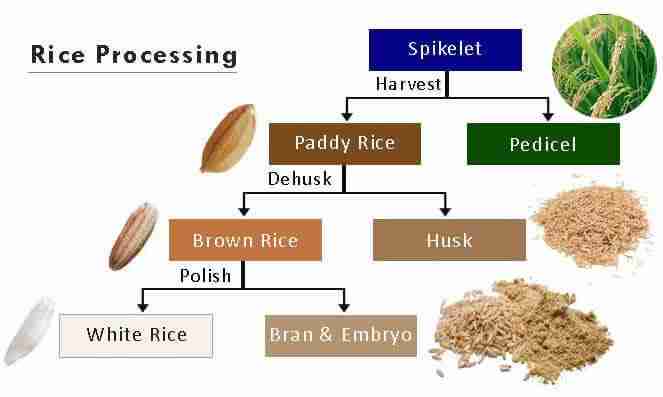

Incorporating advanced sieving systems and multi-stage milling approaches can also provide substantial improvements in yield and quality. These systems allow for a more uniform separation of husk, bran, and rice, reducing the chances of contamination and enhancing purity. Moreover, advancements in optical sorting technology can now detect and eliminate discolored or damaged grains before packaging. By integrating these innovative techniques and technologies, millers not only boost their productivity but also cater to the growing demand for high-quality rice in the market.

| Technique | Benefit |

|---|---|

| Temperature Control | Preserves flavor and nutrients |

| Moisture Management | Reduces grain breakage |

| Advanced Sieving Systems | Ensures purity and uniformity |

| Optical Sorting | Eliminates defective grains |

Wrapping Up

As we conclude our exploration of the remarkable innovations in paddy processing machines, it is clear that these advancements are not merely technological feats but pivotal contributors to the future of agriculture. By enhancing efficiency, reducing labor demands, and optimizing grain quality, these machines are transforming the way we harvest and process one of the world’s most vital staple foods.

The journey of paddy, from field to table, has been significantly altered, presenting opportunities for farmers, entrepreneurs, and consumers alike. As we look towards a future shaped by ongoing innovation and sustainability, the impact of these machines will resonate through the global food supply chain, ensuring that the fruits of our labor are harvested with care and processed with precision.

In this ever-evolving landscape, it remains crucial to embrace these changes and continue to seek out new solutions that support both agricultural practices and food security. The next chapter in our agricultural narrative is unfolding, and it holds the promise of a more efficient, sustainable, and bountiful future for all. Let us cultivate this potential together.