From Paddy to Perfect: Inside a Rice Processing Plant

In the quiet corners of rural landscapes, where lush green fields stretch as far as the eye can see, a humble grain undergoes a remarkable transformation. Rice – the cornerstone of many cultures and cuisines – journeys from paddy fields to polished perfection within the walls of processing plants. Here, the alchemy of agriculture meets the precision of technology, creating a vital link between farmer and consumer. In this article, we delve deep into the heart of a rice processing plant, uncovering the intricate processes, expert craftsmanship, and technological innovations that ensure each grain is not only nurtured but also meticulously refined. Join us as we explore the seamless transition from ear to table, shedding light on the essential yet often overlooked steps that bring this staple food to our plates.

The Journey of Rice: Understanding the Paddy Harvesting Process

The journey of rice begins in lush green fields, where farmers diligently attend to their paddies. Harvesting this staple crop is often a communal affair, steeped in tradition and teamwork. As the golden grains sway gently in the breeze, the telltale signs of ripeness emerge: the leaves start to lose their vibrant hue, and the grains beneath their protective husks firm up. The labor-intensive process typically unfolds as follows:

- Preparation: Farmers clear the fields and ready their tools, often using sickles or modern harvesters.

- Cutting: Workers manually or mechanically cut the stalks just above the soil, ensuring minimal crop loss.

- Gathering: The cut stalks are bundled and collected, often by women and children to aid in efficiency.

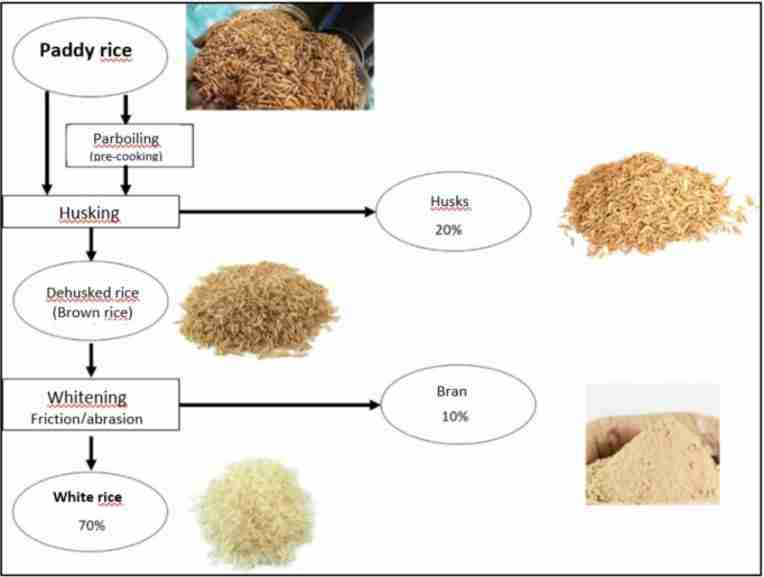

Once harvested, the rice undergoes further steps before making its way to the processing plant. The initial drying phase is crucial, as moisture levels must be reduced to prevent spoilage. This is often accomplished using natural sunlight or mechanical dryers. After drying, the next phase involves husking to separate the grains from their protective outer layer. At this stage, the journey transitions to a more industrial environment where machines take over. Key processes in this setting include:

| Process | Description |

|---|---|

| Husking | Removal of the outer husk from the rice grains. |

| Polishing | Smoothing the surface of the grains for aesthetic appeal. |

| Sorting | Grains are sorted based on size and quality to ensure uniformity. |

Unveiling the Machinery: Key Technologies in Rice Processing

Within the heart of every rice processing plant lies an array of sophisticated technologies designed to transform the raw paddy into the polished grains we find on our dining tables. At the outset, *paddy separators* play a crucial role by utilizing a myriad of factors—such as weight, size, and specific gravity—to separate the grains from unwanted materials like husks and stones. Following this, the *dehusking machine* employs the use of rubber rollers, effectively removing the outer husk without damaging the inner grain. This delicate balance of force and precision is further enhanced by *rice milling equipment*, which encompasses a series of stages to refine the rice perfectly, including whitening and polishing processes that leave the grains gleaming in their final state.

In addition to these core machines, advanced technologies now include *color sorters* that utilize high-resolution cameras and image processing to detect and eliminate any discolored or defective grains. This not only helps in maintaining quality but also significantly impacts the marketability of the rice. Moreover, the implementation of *automated packaging systems* ensures that the finished product is efficiently packed while maintaining hygiene standards. To illustrate the various essential machines used in modern rice processing, the following table summarizes their primary purposes:

| Machine | Function |

|---|---|

| Paddy Separator | Separates grains from impurities |

| Dehusking Machine | Removes husk from paddy |

| Rice Mill Equipment | Mills rice to desired quality |

| Color Sorter | Eliminates defective grains |

| Automated Packaging System | Packages rice hygienically |

Quality Control in Action: Ensuring Excellence at Every Stage

At the heart of a rice processing plant, quality control manifests through rigorous procedures that scrutinize every grain. From the moment paddy arrives, it is subjected to a series of examinations, ensuring it meets the standards of excellence expected by consumers. The journey begins with visual inspections that identify impurities and foreign materials. Following this, the grains undergo moisture analysis to determine their suitability for processing. Each stage is crucial, as even the smallest defect can compromise the final product. Checkpoints throughout the facility guarantee that the quality metrics remain high as paddy transitions to milled rice.

As the processing continues, advanced technology plays a critical role in maintaining quality. Automated systems equipped with color sorters and laser scanning technology ensure that only the best grains make the cut. Additionally, laboratory assessments test for texture, taste, and nutritional value, providing a comprehensive profile of the rice being produced. The culmination of these efforts is reflected in the final inspection phase, where a dedicated team conducts both mechanical and sensory evaluations, preparing a batch for shipping. Below is a summary of the key quality control metrics monitored throughout the process:

| Quality Control Metric | Importance |

|---|---|

| Visual Inspection | Initial impurity detection |

| Moisture Content | Affects storage and cooking quality |

| Color Sorting | Removal of discolored grains |

| Texture Analysis | Ensures desired mouthfeel |

| Taste Testing | Verifies flavor profile |

Sustainable Practices: Recommendations for a Greener Rice Industry

As the rice industry faces increasing scrutiny regarding its environmental impact, the adoption of sustainable practices has become essential. One impactful method includes integrated pest management (IPM), which combines biological control, habitat manipulation, and targeted use of pesticides to minimize environmental damage. Utilizing cover crops can also improve soil health and nutrient retention while reducing erosion. These practices not only enhance the output quality but also promote biodiversity and ecological balance within rice farming systems.

Moreover, the implementation of water-saving techniques such as alternate wetting and drying (AWD) can significantly reduce water usage, making rice production more sustainable. Farmers can also invest in renewable energy sources, like solar panels, to power processing facilities, which decreases reliance on fossil fuels. Additionally, adopting sustainable packaging will not only help reduce waste but also appeal to environmentally conscious consumers. To facilitate these changes, the industry can support training programs that equip farmers with the necessary skills and knowledge to adopt these eco-friendly practices.

Wrapping Up

As we conclude our exploration of the journey from paddy to perfect, it becomes clear that the humble grain of rice undergoes a remarkable transformation within the walls of a processing plant. Each stage of this intricate process is a testament to the dedication and expertise of those who work tirelessly behind the scenes to ensure that what ends up on our plates is of the highest quality. From the gentle husking that unveils the pearl-like grains to the meticulous polishing that brings out their luster, every step reflects a blend of tradition and innovation.

Understanding the complexities involved in rice processing not only deepens our appreciation for this staple but also highlights the importance of sustainable practices in an ever-evolving industry. As we savor the diverse dishes that rice enhances, let us remember the meticulous journey it undertook to reach us, a journey filled with science, craftsmanship, and a commitment to excellence. The next time you enjoy a bowl of rice, take a moment to remember the many hands, processes, and technologies that made it possible. In doing so, we can honor the rich tapestry of agricultural heritage while looking ahead to an even more sustainable future.