Rice, a staple food for over half of the world’s population, has been cultivated and processed for centuries. The art of rice processing is a delicate dance between tradition and innovation, with essential equipment playing a crucial role in transforming raw grains into the fluffy, fragrant rice we all know and love. From ancient stone mills to cutting-edge modern machinery, the tools used in rice processing have evolved over time to ensure efficiency and quality. In this article, we will explore the essential equipment necessary for mastering the art of rice processing.

Exploring the Vital Role of Rice Mills in Efficient Processing

Rice mills play a crucial role in efficiently processing rice to ensure high-quality end products. One essential piece of equipment in rice processing is the rice huller, which removes the husk from the rice grain. This process is vital in improving the appearance and taste of rice, making it more marketable to consumers.

Another key equipment in rice mills is the rice polisher, which gives the rice its shiny appearance by removing the bran layer. Additionally, the rice grader is used to separate rice grains based on size, ensuring uniformity in the final product. These essential pieces of equipment work together seamlessly to streamline the rice processing process, ultimately contributing to the overall efficiency of rice mills.

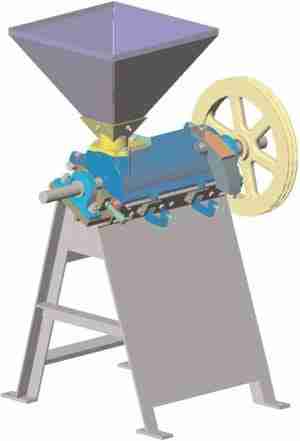

Key Components of a High-Quality Rice Huller for Optimal Results

When it comes to rice processing, having the right equipment is essential for achieving optimal results. One of the key components of a high-quality rice huller is the hulling chamber. This is where the actual hulling process takes place, where the outer layer of the rice grain is removed. A well-designed hulling chamber will ensure that the rice is processed efficiently and with minimal breakage.

Another important component of a high-quality rice huller is the adjustable pressure system. This allows the operator to control the pressure exerted on the rice grains during the hulling process, ensuring that the grains are not damaged in the process. Additionally, a precision feeding mechanism is crucial for consistent and even feeding of the rice grains into the hulling chamber, resulting in uniform processing.

Selecting the Best Rice Polisher for Enhanced Grain Quality

When it comes to rice processing, selecting the best rice polisher is crucial for achieving enhanced grain quality. A rice polisher helps to remove the bran layer from the rice grain, resulting in a shiny appearance and improved texture. With the right equipment, you can ensure that your rice meets the highest standards of quality and is ready for consumption.

There are several factors to consider when choosing a rice polisher for your operation. **Durability** is key, as you want a machine that can withstand the rigors of continuous use. **Efficiency** is also important, as a faster processing time can lead to increased productivity. **Versatility** is another factor to keep in mind, as you may need a polisher that can handle different types of rice varieties. By taking these factors into account, you can find the perfect rice polisher to enhance the quality of your product.

Maintaining Precision with State-of-the-Art Rice Graders

When it comes to the art of rice processing, maintaining precision is key to producing high-quality products that meet consumer expectations. State-of-the-art rice graders play a crucial role in this process, ensuring that every grain is sorted accurately and efficiently. These advanced machines are equipped with cutting-edge technology that allows for precise grading based on size, shape, and color.

With the help of state-of-the-art rice graders, rice processing facilities can achieve optimal efficiency and consistency in their operations. These machines are designed to handle large volumes of rice while maintaining utmost accuracy in grading. By investing in top-of-the-line equipment, rice processors can streamline their operations and deliver superior products to the market. In a competitive industry where quality is paramount, utilizing state-of-the-art rice graders is essential for success.

In Conclusion

As we conclude our exploration into the art of rice processing and the essential equipment needed, we hope this has provided you with valuable insights into the intricate process of transforming rice grains into the staple food that feeds billions around the world. From the humble farmer to the modern industrial processor, the tools and machinery used in rice processing play a crucial role in ensuring the quality and efficiency of this essential food product. Whether it be the simple mortar and pestle or the sophisticated modern rice mill, each piece of equipment has its own unique role to play in the age-old tradition of rice processing. So next time you enjoy a delicious bowl of rice, take a moment to appreciate the artistry and craftsmanship that goes into each grain that ends up on your plate.