Rice processing is an age-old art that requires precision, care, and the right tools to achieve the perfect grain. In this guide, we will explore the equipment needed to master the art of rice processing, from traditional methods to modern technologies. Join us as we delve into the world of rice processing and uncover the key tools that are essential for producing this humble grain in all its glory.

A Comprehensive Overview of Rice Processing Equipment

Rice processing involves a series of intricate steps that require specialized equipment to ensure the highest quality and efficiency. From cleaning and hulling to polishing and packaging, each stage of the process demands specific tools and machinery. One essential piece of equipment is the rice huller, which removes the tough outer husk of the rice grain to reveal the edible kernel inside. The rice huller is equipped with abrasive surfaces that rub against the grains, effectively stripping away the husk without damaging the delicate kernel.

Another crucial machine in the rice processing arsenal is the rice polisher, which gives the grains their characteristic glossy appearance. The rice polisher works by removing the bran layers on the surface of the rice grains, resulting in a smoother texture and improved appearance. Additionally, the rice grader is used to separate the grains into different sizes based on their lengths, ensuring uniformity in the final product. By utilizing a combination of these specialized pieces of equipment, rice processors can streamline their operations and deliver high-quality rice products to consumers around the world.

Essential Machines for Cleaning and Husking Rice

Rice processing requires a range of essential machines to ensure a smooth and efficient operation. One key machine for cleaning and husking rice is the rice huller. This machine is designed to remove the outer husk of the rice grain, leaving behind the edible rice kernel. With its abrasive surface, the rice huller effectively scrapes off the husk, allowing for the production of polished white rice.

Another indispensable machine for rice processing is the rice polisher. This machine is used to remove the bran layer from the rice kernel, resulting in a shiny and polished appearance. By using friction and pressure, the rice polisher helps to enhance the visual appeal of the rice while also improving its texture. Investing in these essential machines can greatly streamline the rice processing workflow and ensure high-quality end products.

Optimizing Polishing and Grading Techniques for High-Quality Rice

When it comes to , having the right equipment is essential. The art of rice processing involves a careful balance of precision and efficiency, and having the proper tools can make all the difference in achieving the perfect grain.

From state-of-the-art milling machines to advanced grading systems, there are a variety of equipment options available to help streamline the rice processing process. Some key equipment to consider includes:

- Rice Huller – Removes the outer husk from the rice grain.

- Rice Polisher – Enhances the appearance and texture of the rice grain.

- Rice Grader – Sorts rice grains by size, helping to ensure uniformity in the final product.

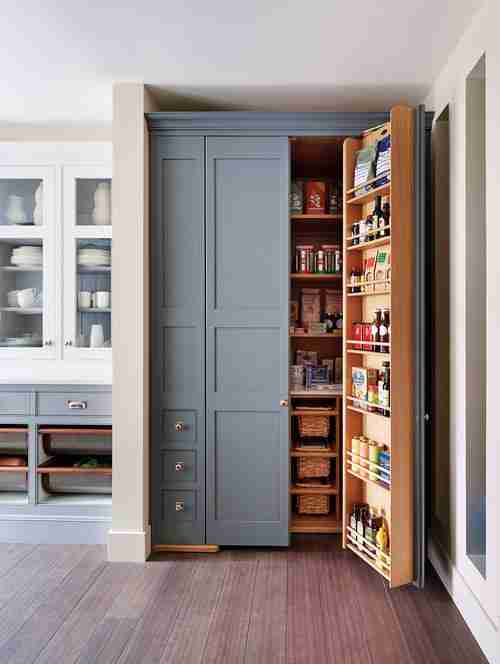

Selecting the Right Storage Solutions for Preserving Freshness and Flavor

When it comes to processing rice, having the right storage solutions is crucial for maintaining freshness and flavor. There are various options available, each with its own unique benefits. Here are some key factors to consider when selecting the best storage solutions for preserving your rice:

- Airtight Containers: Storing rice in airtight containers helps to keep out moisture and air, which can cause rice to spoil faster. Look for containers with a tight seal to ensure optimal freshness.

- Cool, Dark Place: Rice should be stored in a cool, dark place to prevent exposure to light and heat, which can degrade the quality of the rice. Consider storing your rice in a pantry or cupboard away from direct sunlight.

- Vacuum Seal Bags: Vacuum seal bags are a great option for long-term storage of rice. These bags remove air from the packaging, helping to preserve the freshness and flavor of the rice for an extended period.

| Storage Solution | Benefits |

| Airtight Containers | Keeps out moisture and air |

| Cool, Dark Place | Prevents exposure to light and heat |

| Vacuum Seal Bags | Long-term freshness preservation |

To Conclude

From traditional hand tools to modern machinery, the art of rice processing has come a long way in meeting the demands of today’s consumers. With the right equipment and techniques, rice farmers and processors can ensure high-quality products that satisfy the tastes and preferences of a diverse market. By understanding the intricate process of rice milling and utilizing the appropriate tools, we can appreciate the craftsmanship and dedication that goes into providing us with this staple food. So next time you enjoy a delicious bowl of rice, take a moment to consider the artistry and expertise behind its processing. Happy milling!