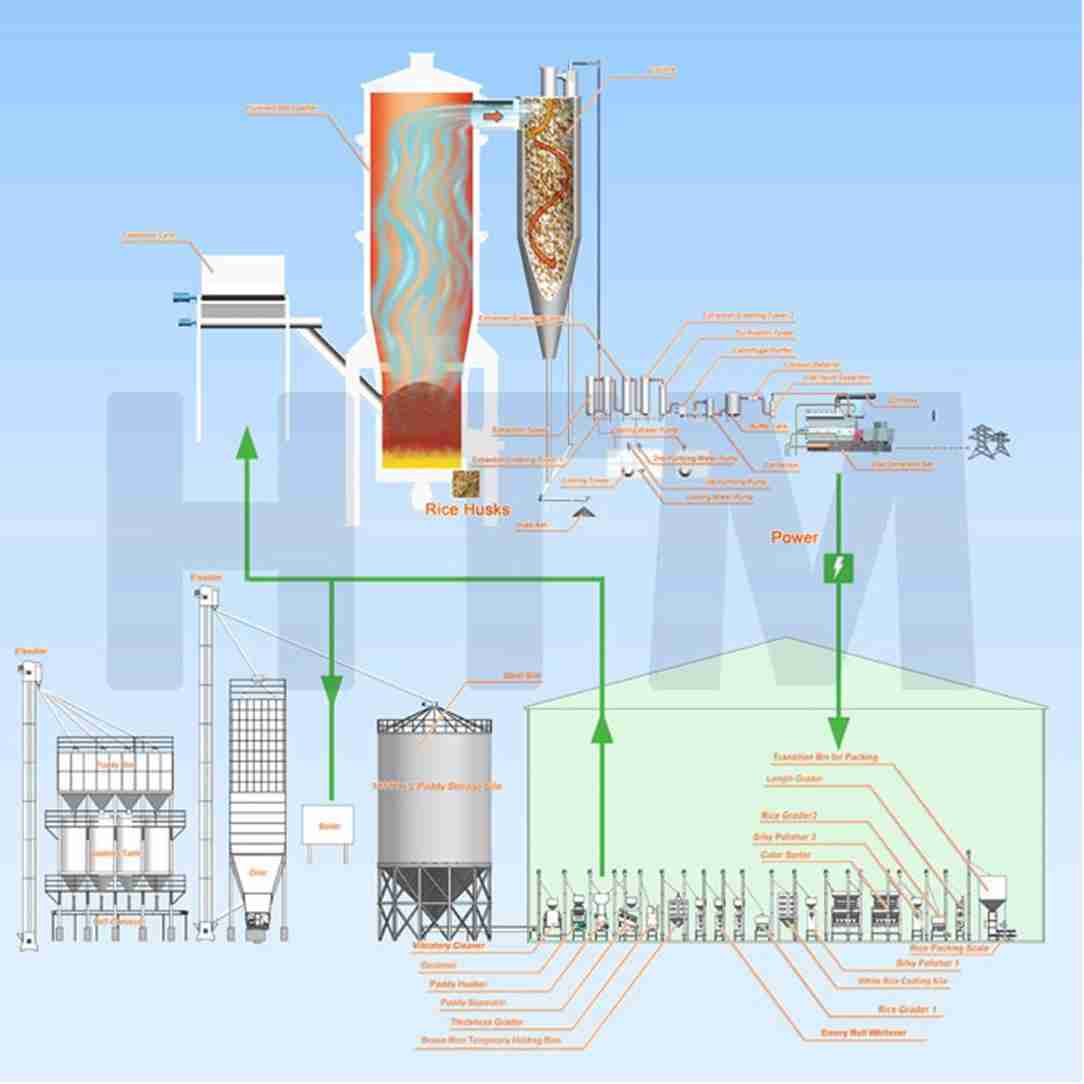

Rice Processing

Rice Processing is a series of stages aimed at enhancing the quality and appeal of rice for market consumption. Initially, rice whitening removes the outer bran layer, improving the rice’s appearance and edibility. This is followed by sifting, which separates broken grains from whole ones, ensuring product uniformity. Length grading sorts grains by size, crucial for quality control. Silky polishing then gives rice a smooth, shiny finish, extending its shelf life. Color sorting employs optical sensors to eliminate discolored grains, ensuring visual consistency. The process concludes with precise weighing and packaging, readying the rice for distribution. Each step is vital for maintaining the standards expected by consumers worldwide.

Inside a Parboiled Rice Processing Plant: Innovations and Insights

Step inside a parboiled rice processing plant, where ancient grains meet modern technology. Here, steam and precision converge to enhance nutrition and texture, showcasing innovations that transform raw rice into a staple fit for the future.

From Field to Bowl: The Art and Science of Rice Processing

"From Field to Bowl: The Art and Science of Rice Processing" unveils the journey of rice, transforming it from golden fields to steaming bowls. This intricate blend of tradition and technology ensures quality and flavor, celebrating a staple that nourishes millions.

From Field to Plate: The Art and Science of Rice Processing

From the lush, green paddies to the bustling kitchens, rice undergoes a remarkable transformation. This journey blends art and science, where skilled hands and advanced technology converge to unlock the grain’s full potential – nourishing bodies and cultures alike.

Unlocking Efficiency: The Future of Rice Processing Equipment

As the global demand for rice surges, innovative processing equipment is revolutionizing efficiency. From automated milling to smart sorting technology, these advancements promise to enhance yield while minimizing waste, shaping a sustainable future for rice production.

Transforming Grains: Innovations in Rice Processing Equipment

In the ever-evolving landscape of food technology, innovations in rice processing equipment are reshaping the way we transform grains. Enhanced milling techniques and automated systems promise increased efficiency, quality, and sustainability for rice production.

Inside the Parboiled Rice Processing Plant: A Journey Unveiled

Step inside the parboiled rice processing plant, where grains undergo a metamorphosis. Steam rises as rice is soaked, steamed, and dried, revealing a meticulous journey of transformation. Here, tradition meets innovation, creating nourishment for countless tables.

Unlocking Quality: Innovations in Rice Processing Equipment

Innovations in rice processing equipment are redefining grain quality and efficiency. From automated milling to advanced sorting technologies, these breakthroughs not only enhance yield but also ensure that every grain meets the highest standards of excellence.

Transforming Grains: A Guide to Rice Processing Equipment

In the heart of agriculture, rice processing equipment transforms humble grains into culinary staples. From milling to polishing, each machine plays a vital role, enhancing quality and ensuring efficiency—a vital guide for modern food production.

Transforming Grains: A Deep Dive into Rice Processing Machines

In the world of agriculture, rice processing machines are unsung heroes, seamlessly transforming raw grains into market-ready products. From husking to polishing, these ingenious devices enhance efficiency, ensuring quality and sustainability in every grain.

From Grain to Gourmet: The Journey of Rice Processing

From the lush paddies to the polished plate, the journey of rice transforms humble grains into gourmet delights. Through milling, sorting, and packaging, each step enhances flavor and texture, celebrating this versatile staple in culinary traditions worldwide.