Unlocking Quality: The Essential Role of Rice Milling Machines

In the bustling heart of agricultural economies, rice stands as a staple food, nourishing billions across the globe. Yet, the journey from paddy fields to the dinner table is not merely a path paved with sunshine and time; it demands precision, innovation, and care, especially during the critical processing stages. At the forefront of this transformation are rice milling machines—unsung heroes that play a vital role in defining the quality of the final product. These intricate machines do more than just mill; they unlock the potential of rice, enhancing its flavor, texture, and nutritional value. This article delves into the essential role that rice milling machines play in optimizing production, ensuring sustainability, and meeting the ever-evolving demands of consumers. Join us as we explore the technology that turns rough grains into culinary treasures, revealing the craftsmanship behind this crucial stage of food processing.

Understanding the Rice Milling Process and Its Impact on Quality

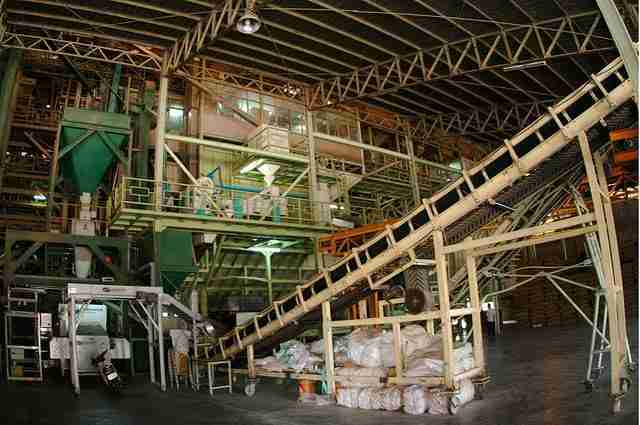

The rice milling process is a pivotal aspect of transforming paddy into the high-quality rice that consumers expect. This journey begins with the careful cleaning of paddy, followed by husking, where the outer husk is removed. The resulting brown rice undergoes a series of milling steps, including whitening, polishing, and grading. Each stage is crucial, as it not only improves the rice’s appearance but also significantly affects its nutritional value and overall quality. Utilizing modern rice milling machines ensures consistency across batches, allowing for a uniform grain size and a polished finish that appeals to consumers.

Moreover, the impact of milling on rice quality is multifaceted, influencing factors such as taste, texture, and shelf life. A well-milled grain retains essential nutrients, while excessive milling can lead to a loss of vitamins and minerals. Some of the key factors affected by milling include:

- Kernel integrity: Proper milling preserves the whole grains without unnecessary breakage.

- Aroma and flavor: The milling technique can enhance or diminish the rice’s natural scent and taste.

- Cooking characteristics: Uniform grain size leads to even cooking and better texture.

| Milling Step | Effect on Quality |

|---|---|

| Cleaning | Removes impurities that affect taste. |

| Husking | Initiates the transformation to brown rice. |

| Whitening | Enhances visual appeal and removes bran. |

| Polishing | Improves texture and flavor. |

| Grading | Ensures consistent quality across products. |

Key Features to Look for in Advanced Rice Milling Machines

When investing in advanced rice milling machines, several key features can significantly enhance the efficiency and quality of your operations. Opt for machines equipped with multi-functional capabilities, allowing for various processes like husking, polishing, and grading in a single setup. This versatility reduces the need for multiple machines, streamlining the production line and saving valuable space in your facility. Additionally, consider machines that incorporate automated adjustments for moisture content and temperature control to maintain consistency and quality in the final product. These features not only enhance the processing quality but also improve energy efficiency, ultimately leading to cost savings.

Another vital aspect is the usability and maintenance of the milling machine. Look for intuitive control systems that provide easy operation and monitoring of production metrics. Advanced models often feature sensor technology to alert operators of any irregularities or maintenance needs, minimizing downtime and ensuring smooth operations. Furthermore, machines made with high-quality materials and easy-to-replace components are more durable, which means less frequent replacements and lower long-term costs. These considerations will not only enhance the functionality of your rice milling process but also provide peace of mind regarding reliability and future performance.

Maintaining Consistency: The Importance of Regular Equipment Maintenance

In the world of rice milling, the performance and efficiency of machines hinge significantly on regular maintenance. Over time, even the most robust equipment can succumb to wear and tear, leading to decreased productivity and compromised quality of the output. To prevent costly breakdowns and ensure consistent operation, it’s vital to adhere to a disciplined maintenance schedule. This proactive approach can help identify potential issues before they escalate, minimizing downtime and fostering a smoother workflow. Regular checks can include tasks such as:

- Routine Cleaning: Ensuring that rice husks and dust don’t accumulate, which can affect performance.

- Lubrication of Moving Parts: Essential for reducing friction and preventing wear.

- Calibration Checks: Making sure that machines are operating at optimal settings helps to maintain precision in milling.

Moreover, establishing a habit of regular maintenance habits cultivates a culture of quality within rice production businesses. This consistency not only enhances machine lifespan but also influences the quality of rice produced, leading to higher customer satisfaction. A well-maintained milling machine operates more effectively, preserving the integrity of the grain while maximizing yield. Consider the following table that highlights essential maintenance tasks and their frequency:

| Maintenance Task | Frequency |

|---|---|

| Check Oil Levels | Weekly |

| Inspect Blades | Monthly |

| Calibrate Machine Settings | Quarterly |

| Complete Overhaul | Annually |

By integrating these practices, rice milling operations can not only enhance productivity but also reinforce reliability in the quality of their final product. Ultimately, consistent maintenance turns every milling session into an opportunity to uphold high standards, making it an indispensable part of the rice milling process.

Future Innovations in Rice Milling Technology and Their Benefits

As the demand for high-quality rice continues to rise, the future of rice milling technology is leaning towards significantly enhanced efficiency and sustainability. Innovative machines are being designed with state-of-the-art sensors and AI-driven algorithms that monitor each stage of milling to ensure optimal grain treatment. These advancements not only reduce waste but also enhance the nutritional profile of the rice. The integration of automated quality control systems will allow for real-time adjustments, ensuring that processors can meet the exacting standards set by consumers and markets alike.

Moreover, the advent of sustainable milling practices that incorporate renewable energy sources is set to revolutionize the industry. For instance, solar-powered milling equipment could drastically lower operational costs while minimizing the carbon footprint. Other innovations like water-saving technologies, which recycle water used in milling, will make the process more environmentally friendly. The future of rice milling promises not only improved yield and efficiency but also a commitment to environmental stewardship, thereby benefiting farmers, consumers, and the planet.

| Innovation | Benefit |

|---|---|

| AI-Driven Algorithms | Optimizes grain treatment and reduces waste |

| Automated Quality Control | Real-time adjustments for superior quality |

| Solar-Powered Mills | Decreases operational costs and carbon footprint |

| Water Recycling Systems | Enhances sustainability and reduces resource use |

To Wrap It Up

As we draw the curtain on our exploration of rice milling machines, it becomes clear that these unassuming marvels play a pivotal role in transforming raw grain into a staple that nourishes billions. The process of unlocking quality is not merely about efficiency; it embodies the delicate balance between innovation and tradition, ensuring that each grain is treated with the utmost care. From advanced technology to sustainability practices, rice milling machines are at the forefront of an industry that not only feeds the world but also honors its agricultural roots.

As we look ahead, the evolution of rice milling technology will continue to adapt, driven by the need for quality and sustainability in food production. Embracing these advancements will not only enhance the dining experience but also ensure that future generations can enjoy this fundamental aspect of global cuisine. In understanding the essential role of rice milling machines, we gain a deeper appreciation for the journey our food takes from field to table, reminding us that every grain has a story to tell. The commitment to quality and innovation in rice milling is not just a business endeavor; it’s a crucial step toward feeding the future sustainably.