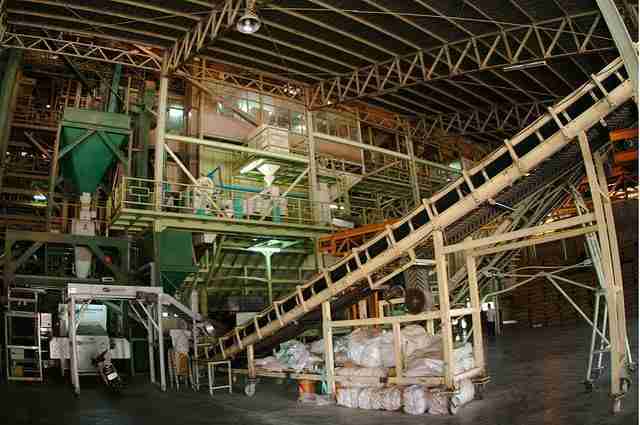

In the heart of agricultural innovation lies a transformative force that is reshaping the landscape of rice production—the commercial rice milling machine. As humanity grapples with the challenge of feeding a burgeoning population, the efficient processing of one of the world’s staple crops has never been more critical. Gone are the days of labor-intensive milling practices that often produced inconsistent results. Today, cutting-edge technology is taking center stage, unlocking the potential of rice milling through precision, efficiency, and sustainability. This article delves into the rise of commercial rice milling machines, exploring their impact on the agricultural sector, the economy, and food security. Join us as we examine how these machines are not just tools, but powerful catalysts driving innovation and growth in the world’s rice markets.

Understanding the Evolution of Rice Milling Technology

The journey of rice milling technology has been nothing short of transformative, blending tradition with innovation to respond to the increasing demands of global food supply. Initially, manual methods dominated the landscape, utilizing simple tools like mortars and pestles, which required significant time and labor. As agricultural practices advanced, the need for efficiency led to the introduction of powered milling machines in the 19th century. These early machines, though rudimentary by today’s standards, marked a significant turning point that paved the way for more sophisticated technologies. Key improvements in rice milling include:

- Introduction of mechanized huskers and polishers

- Development of integrated systems for hulling and whitening

- Advancements in grain handling and storage techniques

Over the decades, the evolution continued with the introduction of computerized systems, enhancing precision and reducing waste. Modern rice milling machines showcase sophistication through automation, allowing millers to maintain consistent quality control while maximizing output. Some striking features include:

- Real-time monitoring for optimal milling adjustments

- Energy-efficient designs that reduce the carbon footprint

- User-friendly interfaces for seamless operation

Examining the impact of these enhancements reflects a broader trend toward sustainability and resource efficiency in the milling industry. The following table summarizes some of the major technological advancements:

| Era | Key Technology | Impact |

|---|---|---|

| 19th Century | Powered Mills | Increased productivity and reduced labor time |

| Mid-20th Century | Automated Machines | Enhanced efficiency and consistency in quality |

| 21st Century | Smart Technology | Data-driven decisions and sustainability focus |

Key Features of Modern Commercial Rice Milling Machines

Modern commercial rice milling machines have transformed the landscape of rice processing, integrating advanced technology with user-friendly operations. These machines are designed to maximize efficiency while maintaining the highest quality of rice. Key enhancements include:

- Automated Processes: Reducing manual labor with automatic feeding and milling functions, enhancing productivity.

- Versatile Processing: Capable of milling various rice types, allowing for adaptability to market demands.

- Energy Efficiency: Utilizing energy-saving technologies, leading to lower operational costs and reduced environmental impact.

- Compact Design: Space-saving designs that fit perfectly within various operational setups without compromising performance.

Moreover, these machines come equipped with sophisticated features aimed at improving the overall user experience and product output. Some notable characteristics include:

- Quality Control Systems: Integrated sensors ensure the rice is polished to perfection while preventing breakage.

- Easy Maintenance: Modular components that simplify regular upkeep, enhancing machine longevity.

- User-Friendly Interfaces: Touch-screen controls that make operation simple and intuitive for operators of varying experience levels.

- Data Monitoring: Advanced analytics capability that tracks output and performance, allowing for real-time adjustments.

Economic Benefits of Investing in Advanced Milling Solutions

Investing in advanced milling solutions not only enhances operational efficiency but also yields substantial economic benefits for rice producers. By adopting state-of-the-art milling technology, businesses can significantly reduce labor costs and waste, leading to improved profit margins. The integration of automated systems and precision equipment ensures a higher yield of milled rice, maximizing output while minimizing loss. With advanced milling solutions, operations can streamline processes, resulting in a quicker turnaround time and an increase in the ability to meet market demands. As a result, producers can capture a larger share of the market by offering consistently high-quality products.

Moreover, these innovations promote sustainability, contributing to lower energy consumption and reduced environmental impact. The transition to energy-efficient machines can lead to considerable savings over time, allowing businesses to reinvest those savings into further technology improvements. Furthermore, access to advanced milling solutions opens up new markets by enhancing product quality and meeting the stringent standards of international buyers. This not only fosters economic growth for individual companies but also uplifts entire communities by creating jobs and driving infrastructure development. the shift towards modern rice milling technology sets a solid foundation for long-term economic prosperity.

| Benefit | Description |

|---|---|

| Increased Yield | Advanced technology maximizes milling efficiency, resulting in higher output. |

| Cost Savings | Reduction in labor and operational costs due to automation. |

| Sustainability | Lower energy consumption and reduced waste contribute to environmental goals. |

| Market Expansion | High-quality products meet international standards, tapping into new markets. |

Best Practices for Maintaining Optimal Performance in Rice Milling Operations

Ensuring the efficiency and longevity of rice milling operations requires a strategic approach to maintenance and performance optimization. Implementing a rigorous cleaning schedule is essential to prevent contamination and preserve the quality of the final product. Regularly removing husk, bran, and any dust particles from milling equipment not only promotes a healthier work environment but also minimizes wear and tear on machinery. Furthermore, maintaining a steady supply of spare parts and consumables can significantly reduce downtime and ensure seamless operation. Consider the following maintenance tips:

- Regular Inspection: Conduct monthly checks on all machinery to catch potential issues before they escalate.

- Scheduled Lubrication: Keep moving parts well-lubricated to reduce friction and enhance performance.

- Temperature Monitoring: Use temperature sensors to prevent overheating in critical areas.

- Operator Training: Empower your team with training on best practices to operate machinery efficiently.

In addition to proactive maintenance, leveraging technology can enhance operational performance. Integrating automation and monitoring systems into the milling process facilitates real-time tracking of production rates and equipment health. This data allows operators to make informed decisions, such as adjusting milling speeds or scheduling maintenance during low-peak hours. Consider utilizing the following technologies:

| Technology | Description |

|---|---|

| Automation Systems | Streamlines processes by automating feeding, milling, and packaging. |

| IoT Sensors | Provides real-time monitoring of machine conditions and alerts for maintenance. |

| Data Analytics | Analyzes production data to optimize workflow and improve yield efficiency. |

Final Thoughts

As we stand at the crossroads of agriculture and technology, the rise of commercial rice milling machines represents more than just an advancement in processing; it symbolizes a transformative journey towards unlocking the full potential of rice as a staple food. These machines, built on innovation and efficiency, are not only enhancing productivity but also fostering economic growth in communities where rice cultivation is a way of life.

With their ability to streamline operations and improve quality, commercial rice milling machines are becoming essential allies for farmers and entrepreneurs alike. As we look towards the future, it is clear that embracing these technologies will pave the way for sustainable practices, economically viable enterprises, and ultimately, a more secure food supply. As industries continue to evolve, so too will the tools that drive them forward, marrying tradition with modernity in a partnership that promises to benefit us all.

In reflecting on this journey, we recognize that the impact of rice milling extends far beyond mere grains; it touches lives, cultures, and economies. As we unlock the potential of these machines, we unleash a wave of possibilities that could reshape rice production and pave the way for future innovations in agriculture. The future is ripe with promise, and it’s an exciting time to be a part of this evolving narrative. Here’s to the future of rice milling—one that stands on the foundation of ingenuity and the unwavering spirit of those who cultivate the land.