In the heart of agricultural innovation lies a transformative technology that promises to redefine the landscape of rice production: the combined rice milling machine. As the global demand for rice rises, so too does the need for more efficient and versatile milling solutions capable of streamlining processes and maximizing yield. This article embarks on a journey to explore the multifaceted advantages of these machines, unveiling how they not only enhance operational efficiency but also cater to the diverse needs of farmers and millers alike. By combining various stages of rice processing into a single, cohesive system, these machines stand as a testament to ingenuity in the agricultural sector. Join us as we delve into the world of combined rice milling machines, unlocking the potential they hold for improving productivity and supporting sustainable practices in rice cultivation.

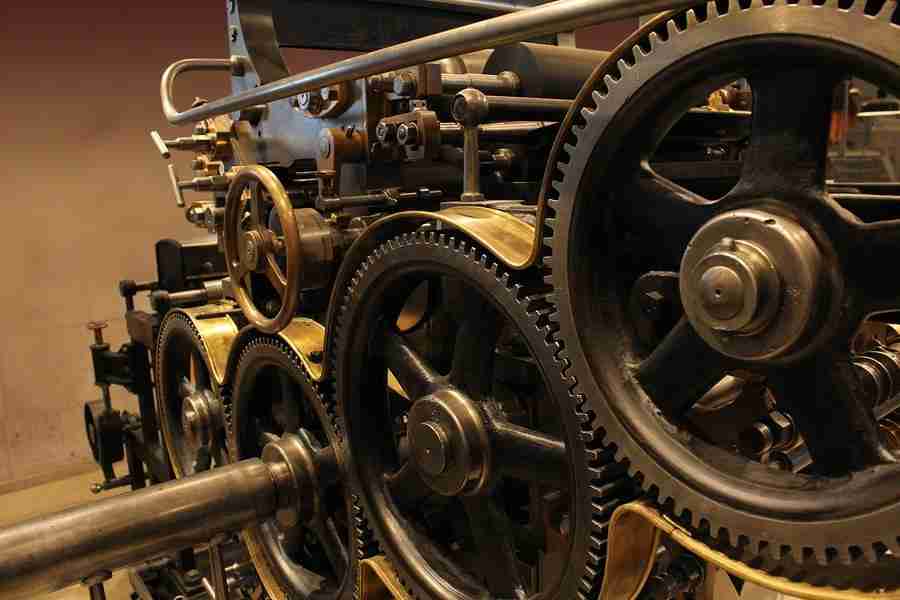

Exploring the Mechanisms Behind Combined Rice Milling Machines

The intricacies of combined rice milling machines are fascinating, as they integrate multiple processes into a single, efficient system. These machines typically incorporate several functionalities that enhance productivity while maintaining grain quality. Key mechanisms at work include:

- Husking: The initial phase involves removing the outer husk using a combination of abrasion and friction.

- De-stoning: This step ensures that any stones or foreign materials are separated from the rice before further processing.

- Whitening: The process of polishing the rice grains to remove bran layers, often employing a combination of air suction and abrasives.

- Grading: The final mechanism sorts rice by size, ensuring a uniform product that meets market standards.

Each of these stages operates seamlessly through synchronized components, contributing to the overall efficiency of the milling process. For manufacturers and farmers alike, understanding these mechanisms is essential to maximize output and minimize waste. The following table highlights the advantages of using combined rice milling machines compared to traditional milling methods:

| Feature | Combined Milling Machines | Traditional Milling Methods |

|---|---|---|

| Efficiency | High, with multiple processes in one | Lower, requiring more equipment |

| Space Utilization | Compact design | Requires more floor space |

| Product Quality | Consistent and uniform | Varied quality |

| Labor Requirement | Reduced labor needs | More manual intervention |

Enhancing Productivity through Innovative Technology

In the pursuit of greater efficiency, the adoption of combined rice milling machines has revolutionized agricultural production. These innovative tools integrate multiple milling processes into a single system, drastically reducing operational time and labor costs. By leveraging technology, these machines not only enhance productivity but also ensure higher quality output. The benefits are profound, offering farmers a streamlined approach to rice processing that includes:

- Integrated Processes: Combining husking, whitening, and polishing in one machine minimizes the need for separate equipment.

- Time Efficiency: With reduced processing times, farmers can maximize their production schedules.

- Consistency: Advanced technology ensures uniform quality in every batch, elevating market competitiveness.

Furthermore, the versatility of these machines allows for adaptability to various rice types and processing needs, providing a tailored solution for farmers across regions. By utilizing modular designs and smart controls, operators can adjust settings with ease, enhancing their ability to respond to market demands. Here’s a snapshot of the advantages:

| Feature | Benefit |

|---|---|

| Multi-functionality | Reduces capital investment for multiple machines. |

| Energy Efficiency | Lower operating costs and reduced environmental impact. |

| User-Friendly Interface | Simplifies training and operation, boosting workforce efficiency. |

Choosing the Right Machine for Your Milling Needs

When considering a combined rice milling machine, several crucial factors will guide you toward making an informed decision. Identifying production capacity is essential. Machines are available in various output levels, catering to small-scale operations as well as large agricultural ventures. As you evaluate your needs, consider aspects such as your processing volume and whether the machine supports multiple stages of milling in one seamless workflow. Additionally, pay attention to the types of grains you plan to mill. Some machines are versatile enough to handle various grains, enhancing your operation’s flexibility.

Another significant consideration is the ease of operation and maintenance. User-friendly controls and straightforward maintenance routines can save valuable time and reduce downtime. Look for machines with features like automatic feeding systems, which streamline the processing workflow. Furthermore, the availability of spare parts and after-sales service is crucial to ensure your machine remains operational over time. To make the selection process simpler, refer to the following table that compares key features of popular machines:

| Machine Model | Production Capacity (kg/h) | Grain Types | Maintenance Level |

|---|---|---|---|

| Model A | 500 | Rice, Wheat | Low |

| Model B | 1000 | Rice only | Moderate |

| Model C | 1500 | Rice, Barley | High |

Best Practices for Optimizing Milling Efficiency

Maximizing milling efficiency is crucial for achieving high-quality output while minimizing waste. One effective strategy involves investing in modern technology, such as combined rice milling machines, which integrate multiple processes into a single unit. By streamlining operations, these machines reduce energy consumption and operational time. To further enhance performance, it’s vital to prioritize regular maintenance. A well-maintained machine not only prolongs equipment life but also ensures optimal functioning, which translates to better product quality and reduced downtime.

Another key element in achieving optimal milling efficiency is workforce training. Equipping operators with the skills to operate machinery properly can significantly impact the milling process. Regular training can touch upon critical areas such as:

- Machine settings – Understanding the correct settings for different rice varieties.

- Quality control - Monitoring product output to meet industry standards.

- Process adjustments – Making real-time adjustments based on performance data.

Additionally, implementing a systematic approach to inventory management can lead to reduced waste and improved operational flow. By keeping an accurate log of raw materials and finished products, the milling operation can optimize scheduling and production runs. For instance, the following table demonstrates how a streamlined inventory process can enhance overall efficiency:

| Material Type | Optimal Stock Level (kg) | Current Stock Level (kg) | Action Required |

|---|---|---|---|

| Brown Rice | 1000 | 800 | Replenish |

| White Rice | 1500 | 1600 | No action needed |

| Rice Bran | 500 | 300 | Replenish |

In Summary

Outro

As we conclude our exploration of combined rice milling machines, it’s clear that these innovative tools are more than just a staple in modern agriculture; they represent a pivotal evolution in food processing technology. By merging multiple functions into a single, efficient unit, these machines not only streamline production but also enhance the quality of the final product.

The versatility of combined rice milling machines speaks volumes about the potential for integrating technology in traditional industries. As we move forward, advancements in design and functionality promise to continue unlocking new levels of efficiency, ensuring that both small-scale farmers and large commercial operations can meet the growing demands of a global marketplace.

In the quest for sustainability and productivity, embracing such innovations might just be the key to overcoming future challenges in rice production. As we look ahead, let us remain open to the possibilities that lie within every grain, every machine, and every process that continues to refine the way we feed the world.