Unlocking Efficiency: The Ultimate Guide to Complete Rice Milling Machines

In a world where efficiency dictates progress and innovation fuels industries, rice milling stands as a crucial link in the chain of food production. As one of the staple grains that feeds billions, the process of transforming paddy into polished rice is not just an art; it’s a science that demands precision, expertise, and the right technology. Enter the realm of complete rice milling machines—an impressive symphony of engineering designed to optimize every step of the milling process.

In this ultimate guide, we will delve into the intricate world of rice milling machinery, exploring the various components, technologies, and practices that define the efficiency of modern milling operations. From understanding the mechanics behind these machines to evaluating the impact of technological advancements, this comprehensive resource aims to unlock the secrets of maximizing productivity while ensuring the highest quality end product. Whether you are a seasoned miller, an entrepreneur venturing into the agricultural sector, or simply curious about this essential process, join us as we unveil the keys to transforming raw grain into a refined staple that nourishes communities worldwide.

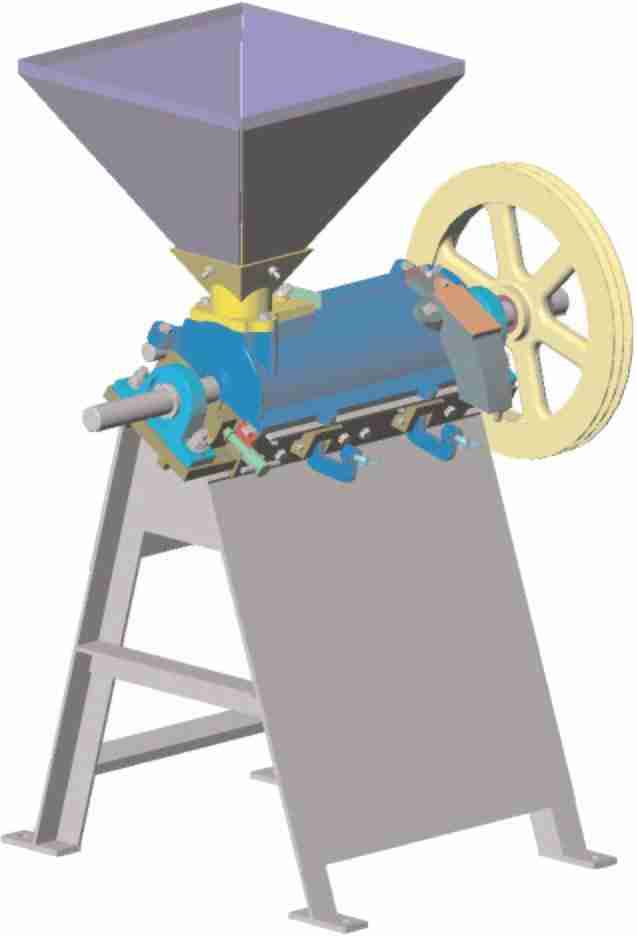

Exploring the Anatomy of Rice Milling Machines

Rice milling machines are marvels of engineering that transform paddy into polished rice through a series of intricate steps. Understanding the anatomy of these machines provides insight into their efficiency and effectiveness in milling operations. At the heart of the process are components such as huskers, whitener, and polishers. Each part plays a pivotal role in ensuring that the rice not only retains its nutritional value but also reaches the desired quality. The huskers remove the inedible outer layer, while whiteners refine the kernel by eliminating bran layers, culminating in the polishers that impart a smooth finish.

Moreover, a comprehensive rice milling machine comprises various auxiliary systems that enhance performance. Key features often include:

- Grading machines: Sort rice grains by size for uniformity.

- Suction systems: Minimize dust and waste during processing.

- Control panels: Allow for precise monitoring and adjustments throughout the milling process.

The integration of these components is pivotal to achieving superior efficiency and throughput. To demonstrate the relationship between these components, the following table outlines the primary functions and purposes:

| Component | Function |

|---|---|

| Husker | Removes husk from paddy |

| Whitener | Polishes rice and removes bran layers |

| Polisher | Gives rice a shiny finish |

Key Features that Enhance Milling Efficiency

When it comes to maximizing productivity in rice milling, several innovative features stand out that not only streamline operations but also enhance overall efficiency. Automated sorting systems leverage advanced sensors to quickly identify and eliminate broken or discolored grains, ensuring only the highest quality end product. Additionally, energy-efficient motors minimize power consumption, providing a sustainable approach while maintaining robust performance. This combination not only reduces operational costs but also aligns with eco-friendly practices increasingly desired in today’s market.

Another critical aspect contributing to elevated milling efficiency is the integration of real-time monitoring systems, which offer insights into machinery performance and maintenance needs. This proactive approach minimizes downtime and allows for adjustments on-the-fly. Moreover, modular design in milling machines facilitates easy upgrades and repairs, making it easier for operators to adapt to changing production demands without the need for extensive overhauls. Such features promote seamless operations, enabling millers to focus on scaling their productivity while ensuring quality remains uncompromised.

Choosing the Right Machine for Your Rice Processing Needs

When selecting a milling machine for rice processing, it’s essential to assess the unique requirements of your operation. Factors such as production capacity, available space, and grain quality must be considered to ensure that you invest in the right equipment. Various models offer features that cater to different scales of operation, from small family-run mills to large-scale industrial plants. Furthermore, consider the type of rice you process; some machines are specifically designed for white rice, while others can handle brown rice or even specialty varieties.

Another crucial aspect is the technology used in the milling machine. Modern machines often incorporate advanced features such as automation, which can significantly enhance efficiency and reduce labor costs. Look for machines that offer the following benefits:

- Energy efficiency: Reduced power consumption

- Versatility: Adaptability to different rice types

- Maintenance ease: Simple cleaning and upkeep procedures

- Quality control: Consistent product output with minimal broken grains

When comparing options, creating a table can help to visualize key specifications and features for easier decision-making:

| Machine Type | Production Capacity (kg/hr) | Key Features |

|---|---|---|

| Small-Scale Mill | 100-200 | Compact design, low energy consumption |

| Medium-Scale Mill | 500-1000 | Automated feeding system, multiple capacity settings |

| Large-Scale Mill | 2000+ | Advanced technology, bulk processing capability |

Maintenance Tips for Longevity and Optimal Performance

To ensure the longevity and optimal performance of your complete rice milling machine, it’s crucial to establish a comprehensive maintenance routine. Regularly inspect and clean the various components, paying special attention to the hulls and grains that may accumulate over time. Schedule weekly checks for parts like the milling chamber, rollers, and screen, and clean them meticulously to prevent build-up that can hinder efficiency. Additionally, lubricating moving parts using appropriate oils can reduce friction and wear, significantly enhancing the machine’s overall lifespan.

Moreover, keeping a detailed log of maintenance activities helps track performance trends and identify potential issues before they escalate. Implement these practical tips to boost your machine’s reliability:

- Daily cleaning: Remove leftover grains and dust after each use.

- Weekly lubrication: Apply lubricants to critical moving components.

- Monthly inspections: Check for wear and tear on belts and motors.

- Annual servicing: Schedule a professional assessment to ensure all parts are functioning optimally.

Furthermore, understanding the machine’s specifications can guide you in using it correctly, thereby minimizing wear caused by misuse. Here’s a simple comparison of maintenance frequency based on machine usage:

| Usage Type | Maintenance Frequency |

|---|---|

| Light Usage | Monthly |

| Moderate Usage | Weekly |

| Heavy Usage | Daily |

By adhering to these maintenance practices, you not only extend the lifespan of your rice milling machine but also ensure it operates at peak efficiency, ultimately enhancing productivity and reducing costly downtimes.

Closing Remarks

navigating the intricate world of rice milling machines need not be a daunting process. As we’ve explored throughout this guide, unlocking efficiency in rice production hinges upon understanding the diverse options available—ranging from traditional methods to cutting-edge technology. By considering factors such as your production needs, budget constraints, and the scale of operations, you can make informed decisions that not only enhance productivity but also contribute to the overall quality of your final product.

As the agricultural landscape continues to evolve, staying informed about advancements in milling technology and emerging best practices will empower you to remain competitive in an ever-changing market. Whether you are a small-scale farmer or part of a large milling operation, embracing the right machinery can transform your workflow, reduce waste, and ultimately lead to greater profitability.

Thank you for joining us on this journey through the world of rice milling machines. May your endeavors in unlocking efficiency yield rich rewards, both in your operations and in the grains you produce. Happy milling!