In a world where food security and agricultural innovation are paramount, a silent revolution is unfolding in the heart of the rice industry. As the global population surges and demand for staple crops intensifies, the traditional methods of rice milling are being challenged to meet the needs of a changing market. “Unlocking Efficiency: The Revolution of Commercial Rice Milling” explores the transformative technologies and methodologies that are redefining how rice is processed. From state-of-the-art machinery to sustainable practices, this article delves into the myriad ways that modern commercial milling operations are enhancing productivity, reducing waste, and ensuring quality. Amidst the complexities of global supply chains and environmental considerations, we invite you to discover how this crucial sector is evolving to feed the future, one grain at a time.

Innovative Technologies Transforming Rice Milling Operations

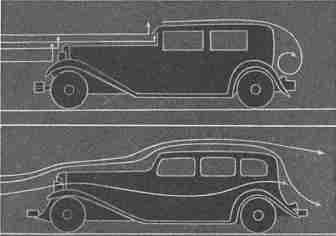

The landscape of rice milling is witnessing a profound shift, driven by the integration of cutting-edge technologies that enhance efficiency and productivity. Smart milling systems equipped with sensors and IoT connectivity are enabling real-time monitoring of operations, thereby allowing millers to optimize processes and minimize waste. Automated machinery powered by AI algorithms can adapt to variations in rice quality, ensuring consistent output and reducing manual intervention. This not only improves operational efficiency but also empowers millers to make data-driven decisions that bolster their competitiveness in the market.

Furthermore, advancements in sustainable practices are gaining traction within the industry. Innovative energy-efficient machines are significantly reducing the carbon footprint of milling operations while lowering energy costs. The use of cloud-based management software streamlines logistics and inventory processes, facilitating smoother supply chain dynamics. Additionally, emerging technologies such as blockchain are enhancing traceability and authenticity in milling, enabling consumers to trust the quality of the rice they purchase. As these technologies merge to create more resilient and agile milling operations, they are setting a new standard for the industry.

Streamlining Supply Chains for Enhanced Productivity

In the competitive landscape of commercial rice milling, optimizing supply chains is paramount to maximizing productivity. By integrating automation and technology, mills can significantly reduce waste and minimize downtime. Incorporating real-time data analytics allows for better decision-making, ensuring that every step—from sourcing raw materials to distribution—is finely tuned. Implementing advanced inventory management systems can also help in maintaining optimal stock levels, ensuring that production never falters due to material shortages. The value of collaboration with suppliers cannot be overstated; establishing robust relationships can lead to improved quality and reliability, ultimately enhancing overall efficiency.

To visualize the impact of streamlined supply chains, consider the following aspects that contribute to productivity enhancement:

| Factors Influencing Productivity | Description |

|---|---|

| Real-Time Monitoring | Allows for instant adjustments to operations based on current performance metrics. |

| Sustainable Practices | Minimizes waste and lowers costs through eco-friendly sourcing and processing. |

| Automated Logistics | Ensures timely deliveries and pick-ups, reducing delays in production. |

By prioritizing these factors, rice mills can not only streamline their operations but also establish a resilient framework that withstands market fluctuations. Embracing innovation and sustainability will pave the way for a future where productivity is continuously elevated, and supply chains are optimized for success.

Sustainable Practices in Rice Processing and Their Impact

In recent years, the rice milling industry has embraced innovative sustainable practices designed to enhance efficiency while reducing environmental impact. By adopting techniques such as water recycling, energy-efficient machinery, and waste management systems, mills are finding ways to lower their operational costs and carbon footprint. These practices not only optimize the use of crucial resources but also contribute to sustainable agricultural systems by ensuring that more rice can be processed with less waste. Some of the key sustainability initiatives include:

- Use of solar energy: Implementing solar panels to power processing plants, reducing reliance on fossil fuels.

- Husk utilization: Transforming rice husks into biofuel or building materials, minimizing waste and generating additional revenue streams.

- Precision milling techniques: Enhancing machinery to maximize yield and minimize grain breakage.

The impact of these sustainable practices extends beyond immediate gains; they foster community resilience and promote responsible resource management. By investing in technologies that prioritize sustainability, rice processors can create a ripple effect throughout the supply chain, positively influencing farming methods, farmer livelihoods, and local economies. For example, through initiatives like crop rotation and integrated pest management, rice mills can support farmers in adopting more environmentally friendly agricultural methods. Below is a simplified table illustrating the beneficial outcomes linked to these sustainable practices:

| Practice | Benefit | Long-term Impact |

|---|---|---|

| Water Recycling | Reduced water use | Conserves local water sources |

| Energy-efficient Machinery | Decreased energy costs | Lower greenhouse gas emissions |

| Waste Management | Less landfill waste | Promotes circular economy |

Best Strategies for Investing in Modern Milling Equipment

Investing in modern milling equipment requires a strategic approach that considers both technological advancements and operational efficiencies. Potential investors should focus on the following aspects to make informed decisions:

- Assessing Technological Compatibility: Ensure that the equipment you are considering can effectively integrate with existing operations and systems. This compatibility can save on training costs and improve overall workflow.

- Evaluating Supplier Reputation: Research manufacturers and suppliers to gauge their standing in the market. Reliable suppliers often offer better support and maintenance services, enhancing long-term investment value.

- Understanding Production Needs: Analyze your production capacity and future growth projections. Selecting equipment that meets both current and anticipated needs can prevent costly upgrades down the line.

Additionally, it is vital to consider the return on investment (ROI) when purchasing modern milling equipment. Look into potential savings and efficiency improvements by comparing:

| Traditional Milling Costs | Modern Milling Costs |

|---|---|

| Higher labor costs due to manual processes | Lower labor costs with automation |

| Inconsistent product quality | Uniform product quality through precision |

| Frequent equipment downtime | Reduced downtime with reliable technology |

it is crucial to plan for ongoing maintenance and upgrades. Investing in equipment that offers easy access to replacement parts and has a proven track record of durability will contribute to long-term efficiency. Building partnerships with service providers can also lead to enhanced performance and lower unexpected costs.

In Conclusion

As we conclude our exploration of the transformative impact of modern technologies in commercial rice milling, it becomes clear that the journey towards greater efficiency is not merely about machinery or processes—it is a testament to innovation, resilience, and sustainability within the agricultural sector. The revolution in rice milling is unfolding at a remarkable pace, driven by a blend of science and tradition, aiming to meet the growing global demand for this staple crop.

By embracing cutting-edge techniques and sustainable practices, stakeholders can not only enhance productivity but also foster environmental stewardship, ensuring that the benefits of rice milling extend beyond profitability. As the industry continues to evolve, the focus on efficiency will undoubtedly pave the way for a more secure and prosperous future.

In this newfound era of rice milling, each grain tells a story—one not just of nourishment but of ingenuity and progress. As we move forward, it is essential that all participants in the rice supply chain collaborate, innovate, and adapt, unlocking opportunities that will resonate for generations to come. The road ahead is filled with promise, and it is an exciting time to be part of this ongoing revolution.