Rice, dubbed as the world’s most important staple food, has undergone countless innovative technologies and processes throughout history to cater to the growing global demand. Among these advancements is the development of combined rice milling machines, offering a comprehensive solution to improve efficiency and productivity in the rice milling industry. In this article, we will delve into the ultimate rice milling solution: combined machine efficiency. Join us as we explore how this cutting-edge technology is revolutionizing the way rice is processed and delivered to millions of tables worldwide.

Heading 1: Streamlining the Rice Milling Process with Combined Machine Efficiency

Rice milling is a crucial step in bringing high-quality rice to our tables. With the advancements in technology, the process has become more efficient and productive. By combining various machine functionalities, rice millers can streamline their operations and improve overall output. This innovative approach not only saves time but also ensures a more consistent quality of rice for consumers.

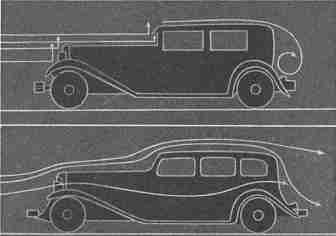

Imagine a seamless integration of cleaning, dehusking, polishing, and grading all in one machine. This is the future of rice milling, where every step is optimized and synchronized to perfection. The combined machine efficiency not only reduces the footprint of the mill but also cuts down on maintenance costs. With less downtime and improved productivity, rice millers can focus on meeting the growing demands of the market while maintaining the highest standards of rice quality.

Heading 2: Maximizing Output and Quality through Integrated Technology

When it comes to maximizing output and quality in rice milling, the key lies in integrating cutting-edge technology into the process. Imagine a system where each component seamlessly works together to deliver the most efficient results. This is where the Combined Machine Efficiency comes into play, revolutionizing the way rice is milled.

With this ultimate rice milling solution, the integration of advanced sorting technology, precision milling components, and automated packaging systems ensures a streamlined operation from start to finish. The result? Enhanced productivity, improved quality control, and ultimately, a higher level of customer satisfaction. Say goodbye to outdated, inefficient processes and embrace the future of rice milling with combined machine efficiency.

Heading 3: Key Features to Look for in a Comprehensive Rice Milling Solution

When searching for the perfect rice milling solution, it is essential to look for key features that will ensure efficiency and productivity. One important feature to consider is the machine’s capacity to handle a large volume of rice while maintaining high-quality output. A comprehensive rice milling solution should have the capability to process different types of rice varieties, ensuring versatility in production.

Another crucial feature to look for is the machine’s automation capabilities. Opting for a rice milling solution that offers automation features such as auto feeding, de-stoning, and polishing can significantly streamline the milling process, reducing the need for manual intervention and increasing overall efficiency. Additionally, a user-friendly interface with advanced monitoring and control systems will further enhance the performance of the rice milling solution, making it the ultimate choice for rice processing businesses.

Heading 4: Tips for Choosing the Right Combined Machine for Superior Results

When it comes to selecting the perfect combined machine for your rice milling needs, there are several key factors to consider. Firstly, think about the capacity of the machine – do you need a smaller unit for occasional use or a larger, more heavy-duty model for continuous operation? Next, look at the different functions that the machine offers. A versatile combined machine that can handle various tasks such as dehusking, polishing, and sorting will provide superior results compared to a machine with limited capabilities.

Another important consideration is the energy efficiency of the combined machine. Opt for a model that is designed to conserve energy and reduce costs in the long run. Additionally, look for machines with easy maintenance and cleaning features to ensure smooth operation and longevity. By taking these tips into account, you can choose the right combined machine that will streamline your rice milling process and deliver exceptional results.

In Retrospect

As we conclude our exploration of the ultimate rice milling solution, it is clear that the combined machine efficiency offers unparalleled benefits in terms of productivity and quality. By harnessing the power of cutting-edge technology and streamlined processes, rice millers can maximize their output and achieve superior results. Embracing innovation and efficiency is key to staying competitive in the ever-evolving rice milling industry. With the combined machine efficiency, the future of rice milling looks brighter than ever. Thank you for joining us on this journey towards a more efficient and sustainable rice processing solution.