In the heart of agrarian societies, where tradition meets innovation, rice has long been a staple grain, feeding billions and shaping cultures. Yet, behind every bowl of fluffy rice lies a complex journey that begins at the farm and culminates in the kitchen. At the center of this transformative process is the rice milling machine, an unsung hero that has evolved dramatically over the years. From rudimentary hand-operated devices to sophisticated, automated systems, these machines have revolutionized not only the efficiency of rice processing but also the quality and safety of the food we consume. In this article, we will explore the fascinating evolution of rice milling machines, tracing their technological advancements and the profound impact they have had on global rice production, economic development, and food security. Join us as we delve into the history and future of this essential machinery, uncovering how innovation continues to reshape the landscape of grain processing.

Understanding the Historical Context of Rice Milling Technology

The journey of rice milling technology can be traced back thousands of years, deeply entwined with agricultural practices and the cultural significance of rice in societies around the world. Early methods primarily involved manual labor using simple tools like wooden mortars and stone pestles. These primitive techniques, while effective, were labor-intensive and time-consuming, limiting productivity and efficiency. As populations grew and urban centers emerged, the need for more efficient processing mechanisms became paramount, leading to innovations that transformed the landscape of rice milling.

Throughout history, advancements in rice milling have mirrored technological progress across various industries. The introduction of mechanical milling in the 19th century marked a pivotal shift, driven by the Industrial Revolution. Key developments included:

- Steam-Powered Mills: Introduced in the early 1800s, these mills significantly increased output and reduced reliance on manual labor.

- Metal Grinders: Replacing wooden components, metal parts enhanced durability and consistency in grain processing.

- Automatic Feeders: Emerging in the late 20th century, these innovations allowed for continuous operation, drastically improving milling efficiency.

| Era | Key Technology | Impact |

|---|---|---|

| Ancient Times | Manual Milling | Labor-intensive; limited output |

| 19th Century | Steam Power | Increased productivity; reduced labor |

| 20th Century | Automated Systems | Enhanced efficiency; high-volume processing |

This continuous evolution has not only improved the quality and quantity of rice produced but has also shaped the economies and cultures of rice-dependent societies. The interplay of technology and tradition remains a fascinating aspect of rice milling history, highlighting how innovations can pave the way for development while respecting the rich heritage of this staple grain.

Emerging Trends in Automation and Efficiency for Modern Mills

The landscape of rice milling is undergoing a significant transformation, driven by automation technologies that enhance productivity and ensure consistency. Mechanized processes now utilize AI-driven predictive analytics that monitor grain quality in real-time, allowing operators to make data-informed adjustments instantly. This level of precision reduces waste and improves overall product quality by ensuring that every grain is processed optimally. Alongside, various mills are increasingly integrating robotics for handling and sorting, allowing for seamless operation and minimizing the risk of human error in labor-intensive tasks.

Moreover, energy efficiency has become a focal point in modern milling machines. Mills are now adopting smart technology solutions that optimize energy consumption based on workload demands. This includes systems that automatically scale operations down during low-demand periods, resulting in significant cost savings over time. Additionally, the implementation of renewable energy sources, such as solar panels, is becoming more prevalent within milling operations, further promoting sustainability in the agricultural sector. These advancements are not just about improving speed; they are about creating a resilient, environmentally friendly process that benefits both producers and consumers alike.

| Feature | Benefit |

|---|---|

| AI-Driven Analytics | Real-time monitoring for enhanced grain quality |

| Robotics in Handling | Minimization of labor errors and increased efficiency |

| Smart Energy Solutions | Cost-effective and environmentally conscious operations |

| Renewable Energy Integration | Supports sustainability in milling practices |

Sustainability in Rice Processing: Innovations and Best Practices

As the global demand for rice continues to surge, the rice milling industry is embracing innovations that not only improve efficiency but also promote environmental stewardship. Modern rice milling machines are now equipped with cutting-edge technology that enhances processing while minimizing waste. For instance, energy-efficient milling machinery utilizes advanced motors and streamlined processes to reduce electricity consumption significantly. Additionally, some designs incorporate automated waste recovery systems, allowing for the repurposing of husks and bran, thereby transforming potential waste into valuable products such as biofuel and animal feed.

Best practices in rice processing are further enhancing sustainability through strategic approaches that prioritize resource optimization. Techniques such as water recycling systems and the implementation of solar energy solutions in milling operations are becoming more widespread. These systems not only lower operational costs but also reduce the carbon footprint of the milling process. To illustrate the benefits of these advancements, consider the following table that summarizes the key innovations and their impacts:

| Innovation | Benefit |

|---|---|

| Energy-efficient milling machinery | Reduces energy consumption |

| Automated waste recovery systems | Transforms waste into valuable products |

| Water recycling systems | Conserves water resources |

| Solar energy integration | Minimizes reliance on fossil fuels |

Future Prospects: Technologies Shaping the Next Generation of Milling Machines

The future of milling technology is on the brink of a major transformation, driven by advancements in automation, artificial intelligence, and precision engineering. Emerging technologies are set to redefine how rice milling machines operate, making them more efficient, user-friendly, and sustainable. Key innovations include smart sensors that monitor grain quality in real-time, ensuring optimal milling conditions. These sensors collect data that can be analyzed using machine learning algorithms, allowing millers to adapt their processes dynamically and achieve higher yields with less waste.

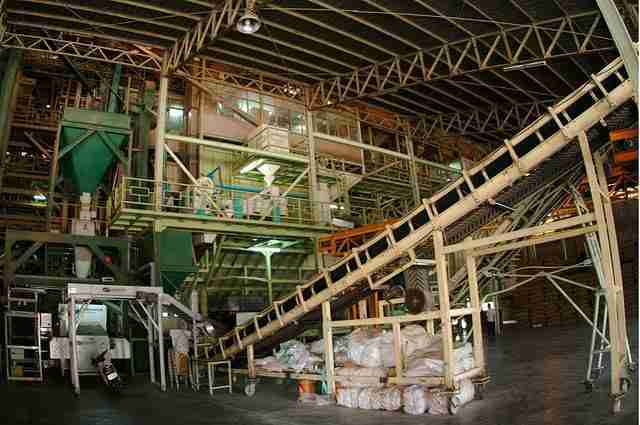

Moreover, the integration of robotics offers the potential to enhance the overall milling process. Automated systems can streamline the workflow, from grain input to final product packaging, minimizing manual labor and human error. Additionally, energy-efficient designs and renewable energy sources are becoming increasingly prevalent, allowing for greener operations. As these technologies continue to evolve, they promise not only to enhance productivity but also to reduce the environmental impact of rice milling. The following table highlights some of the most significant technologies expected to shape the future of milling machines:

| Technology | Impact |

|---|---|

| Smart Sensors | Real-time monitoring of grain quality |

| Machine Learning | Dynamic process adjustment for yield optimization |

| Robotics | Increased automation and reduced labor costs |

| Energy Efficiency | Lower operational costs and reduced environmental footprint |

In Summary

As we conclude our exploration of the evolution of rice milling machines, it’s clear that this journey is much more than a tale of machinery—it’s about the transformation of agriculture, the enhancement of food security, and the cultural significance of one of the world’s staple foods. From the rudimentary hand tools of ancient civilizations to the sophisticated, automated systems of today, the impact of technology on rice milling has been profound and far-reaching.

These machines not only streamline a once-labor-intensive process but also empower farmers to achieve greater yields and improve the quality of the rice they produce. As we look to the future, the continued innovation in this sector promises to yield even more efficient and sustainable methods of milling, ensuring that the grain that feeds millions can be processed with precision and care.

In an ever-evolving agricultural landscape, the humble rice milling machine stands as a testament to human ingenuity, bridging tradition with modernity. As we celebrate the advancements that have revolutionized grain processing, we must also remain mindful of the challenges that lie ahead in balancing technology with sustainability and accessibility. Only time will tell how these intricate machines will adapt to an ever-changing world, but their legacy will undoubtedly continue to shape the culinary and agricultural landscapes for generations to come.