Unlocking the Secrets of Modern Rice Milling Technology

In a world driven by innovation, the humble grain of rice has undergone a remarkable transformation, evolving from a staple of ancient agrarian societies to a cornerstone of modern culinary culture. Yet, the journey of this versatile crop does not end at the harvest; it continues through the intricate processes of milling, where centuries-old traditions meet cutting-edge technology. As we delve into the realm of modern rice milling, we invite you to explore the fascinating interplay between precision machinery, sustainability, and the age-old quest for quality. Join us as we uncover the secrets behind the techniques that not only enhance the purity and taste of rice but also redefine efficiency and environmental stewardship in this essential industry. Welcome to a world where innovation meets tradition, and where every grain tells a story of progress.

Innovative Machinery Transforming Rice Processing

Advancements in rice processing technology have revolutionized the industry, leading to significant improvements in efficiency and product quality. Modern milling machinery incorporates cutting-edge features that enhance the production process while minimizing waste. Key innovations include:

- Automated Optical Sorters: These machines utilize advanced imaging technology to identify and separate defective grains, ensuring only the best quality rice reaches consumers.

- Pre-Milling Treatment Tools: Implementing steam treatment and stabilization techniques helps extend the shelf life of rice while preserving its nutritional value.

- High-Precision Milling Machines: With adjustable settings, these machines allow for precise control over the milling process, resulting in higher yield and reduced broken grain.

The integration of smart technologies, such as IoT devices and machine learning algorithms, has further optimized rice processing. These intelligent systems monitor operational efficiency, predict maintenance needs, and analyze output quality in real-time. The impact of these innovations can be summarized in the following table:

| Innovation | Benefit |

|---|---|

| IoT Monitoring | Real-time data for enhanced productivity |

| Machine Learning Algorithms | Accurate predictions for maintenance |

| Eco-Friendly Technologies | Reduction in environmental impact |

By adopting these innovative solutions, the rice processing industry is not only improving its operational standards but also catering to the growing demand for high-quality, sustainably-produced rice. The future of rice milling is bright as technology continues to unlock new possibilities.

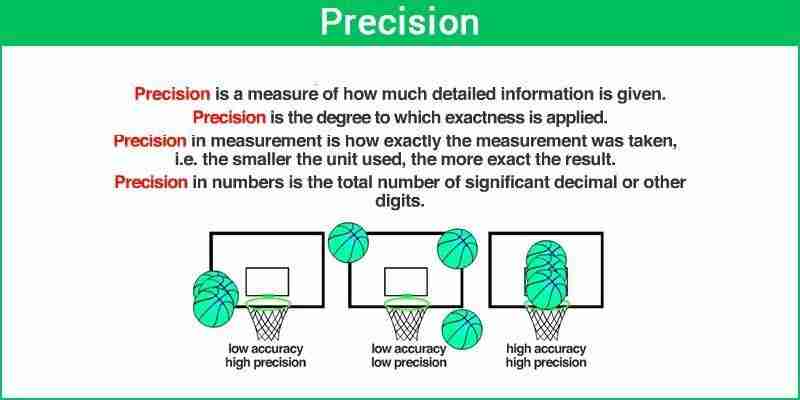

Precision Techniques for Quality Enhancement

In the realm of rice milling, the quest for quality enhancement is driven by a range of precision techniques that ensure optimal outcomes. One such technique includes robotic sorting systems, which leverage advanced imaging technology to identify and remove impurities within the grain. This not only improves the aesthetic appeal of the final product but also elevates its nutritional quality. Other key methodologies involve the use of ultrasonic cleaning, which employs high-frequency sound waves to eliminate debris without damaging the rice, maintaining the integrity of the grains.

To further illustrate the impact of these innovative processes, consider the following table highlighting the benefits of selected precision techniques in modern rice milling:

| Technique | Benefits |

|---|---|

| Robotic Sorting | Enhances purity by removing foreign particles |

| Ultrasonic Cleaning | Preserves rice quality while ensuring cleanliness |

| Optical Grading | Assures uniformity and consistency in size |

| Moisture Control Systems | Prevents spoilage and extends shelf life |

By integrating these cutting-edge techniques, rice millers can significantly enhance their product quality, meeting the demands of an increasingly discerning market. The synergy between these technologies not only streamlines the milling process but also guarantees that consumers receive rice that is not only visually appealing but also rich in flavor and nutrition.

Sustainable Practices in Modern Milling Operations

In contemporary rice milling operations, sustainable practices have emerged as crucial pillars of efficiency and environmental responsibility. One significant approach is the implementation of energy-efficient machinery that reduces the consumption of electricity while maintaining high output levels. By investing in state-of-the-art equipment such as high-frequency oscillating classifiers and automated sorter systems, mills can not only enhance productivity but also minimize their carbon footprint. Furthermore, sourcing materials from local suppliers further contributes to sustainability, as it reduces transportation emissions and supports local economies. This commitment to local sourcing often extends to the adoption of biodegradable packaging materials, ensuring that the environmental impact of products extends as little as possible beyond the milling process itself.

Water management practices represent another critical aspect of sustainability in rice milling. Modern mills are increasingly implementing closed-loop water systems, which minimize water waste by recirculating and treating water used during milling operations. Additional measures include the installation of rainwater harvesting systems and utilization of advanced filtration technologies that ensure clean water is reused multiple times. These efforts not only conserve water resources but also improve operational efficiency by lowering costs associated with water procurement. To illustrate these points, here’s a brief overview of sustainable practices currently being adopted:

| Practice | Description |

|---|---|

| Energy Efficiency | Utilization of low-energy machinery to reduce power consumption. |

| Local Sourcing | Procurement of raw materials from nearby suppliers to cut transport emissions. |

| Water Recycling | Closed-loop systems to minimize water waste and enhance efficiency. |

| Biodegradable Packaging | Using eco-friendly materials for packaging products. |

Future Trends Shaping Rice Milling Efficiency

As the rice milling industry evolves, several key trends are emerging that promise to enhance efficiency and sustainability in rice processing. One of the primary drivers of these trends is the integration of automation and AI technologies. Automated systems can significantly reduce labor costs while improving processing speed and consistency. These systems not only optimize the milling process but also enhance quality control by monitoring every stage in real-time. The usage of Internet of Things (IoT) devices further enables rice mill operators to gather comprehensive data analytics, leading to smarter decision-making processes and timely interventions.

Another notable trend is the shift towards sustainable practices that minimize environmental impact. Modern rice mills are increasingly adopting eco-friendly technologies, such as energy-efficient machinery and waste recycling methods. Implementing renewable energy sources, like solar power, helps facilities become more self-sufficient. Additionally, advancements in water conservation techniques during milling reduce resource waste while ensuring high grain quality. Operators are encouraged to embrace these practices not only for compliance with regulations but also to improve their market competitiveness by appealing to environmentally conscious consumers.

| Technology Trend | Benefits |

|---|---|

| Automation & AI | Reduced labor costs, enhanced consistency, real-time monitoring |

| IoT Devices | Data analytics, smarter decision-making, improved efficiency |

| Sustainable Practices | Lower environmental impact, renewable energy adoption |

| Water Conservation | Resource efficiency, improved grain quality |

In Retrospect

As we conclude our exploration of modern rice milling technology, it is clear that this intricate process is a blend of tradition and innovation. The advancements in milling techniques not only enhance efficiency and sustainability but also reflect an unwavering commitment to quality that resonates throughout the agricultural community. As we continue to embrace these technological strides, we are also reminded of the importance of the artisanal practices that have shaped rice cultivation for centuries.

The journey from paddy to plate is no longer just a simple task; it is now a sophisticated dance of machinery and expertise. By unlocking the secrets of these modern advancements, we are better equipped to address the challenges of food security, optimize resources, and ultimately, nourish the growing global population.

As we look to the future, the fusion of technology with ethical practices will be vital in ensuring that the rich legacy of rice cultivation flourishes alongside contemporary methods. In this ever-evolving landscape, may we continue to seek harmony between innovation and tradition, cultivating not just rice, but a sustainable future for generations to come.