In the heart of agricultural innovation, the landscape of rice milling is experiencing a transformative shift. As the world grapples with the challenges of food security, sustainability, and economic growth, a new breed of rice milling operation is emerging: the combined rice mill. This novel approach integrates multiple functions—processing, packaging, and distribution—into a streamlined system that not only enhances efficiency but also unlocks untapped potential within the rice supply chain. In this article, we explore the rise of combined rice mills, delving into their benefits, technological advancements, and the pivotal role they play in empowering farmers, fostering rural development, and meeting global demand. Join us as we unpack this exciting trend that is redefining the future of rice production and paving the way for a more sustainable agricultural ecosystem.

Exploring Technological Innovations in Combined Rice Mills

In the quest for efficiency and productivity, combined rice mills have emerged as front-runners, showcasing a wealth of technological innovations that are shaping the future of rice processing. These modern facilities integrate multiple processes, such as husking, milling, and sorting, into a single streamlined operation. This not only reduces the need for additional machinery but also minimizes time wastage, energy consumption, and labor costs. Key technological innovations employed in these mills include:

- Automated Control Systems: These systems allow for precise monitoring and control of milling processes, ensuring optimal performance and consistent quality.

- Advanced Milling Equipment: High-efficiency rice hulling machines and multifunctional milling equipment are essential in achieving higher yield rates.

- Quality Sorting Technologies: Optical sorting mechanisms are implemented to enhance the quality of final output by detecting impurities and ensuring uniformity.

Moreover, the adoption of eco-friendly technologies reflects a growing commitment to sustainability within the rice milling sector. Through the integration of renewable energy sources and waste reduction practices, combined rice mills are not only enhancing productivity but also contributing to environmental conservation. The benefits of these innovations extend to the economic realm as well, with the potential for increased profit margins and improved market competitiveness. Below is a table highlighting the advantages of technological integration in rice mills:

| Advantage | Description |

|---|---|

| Increased Efficiency | Reduction in processing time and better resource management. |

| Enhanced Quality | Improved end-product quality with fewer defects and better consistency. |

| Cost Savings | Lower operational costs through energy-efficient machines. |

Sustainable Practices for Improved Efficiency and Productivity

In the quest for enhancing overall operation effectiveness, combined rice mills are pioneering sustainable practices that streamline processes and reduce waste significantly. By integrating traditional milling techniques with modern technology, these mills are able to achieve a dual benefit: maximizing production outputs while minimizing their environmental footprint. Some key sustainable practices include:

- Energy Efficiency: Utilizing energy-efficient machinery and renewable energy sources, such as solar or biomass.

- Water Conservation: Implementing closed-loop water systems to recycle water and reduce consumption.

- Waste Management: Transforming milling by-products into valuable products such as animal feed or biofuels.

This innovative approach not only bolsters productivity but also contributes to a circular economy, where waste is repurposed rather than discarded. As these mills expand their adoption of green technologies, the impact on local communities becomes increasingly positive. Below is a simple overview of the results achieved through sustainable operations:

| Practice | Outcome |

|---|---|

| Energy-saving Machinery | Reduced energy costs by 25% |

| Water Recycling | Conserved 15% of total water usage |

| By-product Utilization | Generated additional revenue streams |

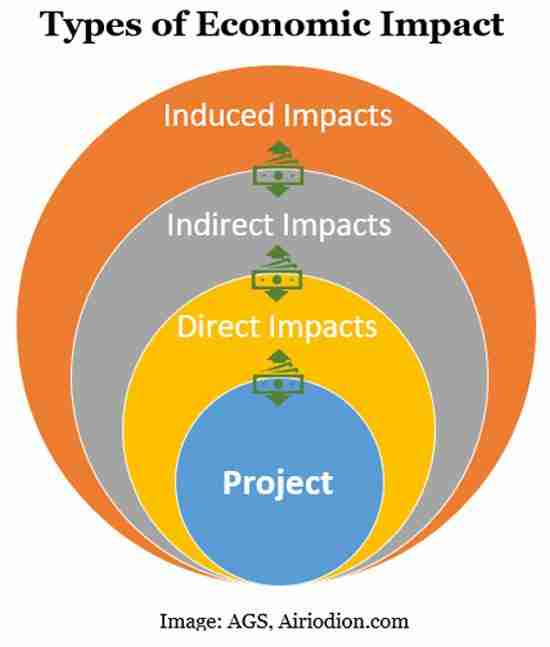

Economic Impacts of Combined Rice Mills on Local Communities

Combined rice mills serve as a catalyst for economic growth in local communities. By streamlining processing operations, these mills reduce production costs and enhance the efficiency of rice milling. This transformation leads to increased profit margins for local producers and gives them a competitive edge in the marketplace. Additionally, combined rice mills often create direct and indirect employment opportunities, bolstering the local economy. The ripple effect can be seen in various sectors, as more job opportunities lead to increased consumption of local goods and services.

Moreover, the establishment of these mills often brings about infrastructure improvements in the surrounding areas. Investments in transportation and utilities facilitate better access to markets, not just for rice, but for other local products as well. These developments elicit a range of benefits:

- Enhanced Market Access: Farmers can easily transport their goods to market.

- Increased Local Revenue: More jobs and better services lead to higher local tax revenues.

- Community Development: Upgraded infrastructure improves overall quality of life.

the rise of combined rice mills signifies a positive shift in local economies, driving growth and sustainability for generations to come.

Strategies for Scaling Up: Best Practices for Success in Rice Milling

Scaling up in rice milling demands a blend of effective management practices and investment in technology. First and foremost, optimizing operational efficiency is crucial. This can be achieved through regular machinery maintenance, ensuring that all equipment runs at peak performance. Utilizing data analytics can also greatly enhance decision-making processes, enabling mill owners to identify bottlenecks and areas for improvement. Moreover, implementing standardized operating procedures helps create consistency in production quality and efficiency. It is also beneficial to invest in staff training sessions, empowering employees to be more skilled in their roles, which can contribute significantly to increased productivity.

Another essential aspect of successful scaling involves leveraging partnerships and fostering collaborations. Building strong relationships with local farmers and suppliers can ensure a steady supply of quality paddy, which is critical for maintaining milling output. Additionally, exploring cooperative models can allow smaller mills to pool resources, share technology, and broaden market access. Employing sustainable practices not only enhances the brand image but can also lead to cost savings in the long run. Highlighted below are some key partnerships and collaboration strategies:

| Collaboration Type | Description |

|---|---|

| Farmer Cooperatives | Join forces with local farmers to secure a reliable paddy supply. |

| Technology Providers | Partner with tech firms to access advanced milling technologies. |

| Logistics Companies | Collaborate with logistics experts for efficient distribution of products. |

| Research Institutions | Engage with academic partners for innovative milling solutions. |

In Retrospect

In a world increasingly aware of the significance of sustainable agriculture and food security, the rise of combined rice mills stands as a beacon of innovation and efficiency. By merging traditional practices with modern technology, these mills are not only enhancing productivity but also unlocking the full potential of rice as a staple crop. As we look to the future, the continued evolution of combined rice mills will play a pivotal role in addressing global challenges— from feeding a growing population to minimizing waste. The journey ahead is ripe with opportunities, inviting stakeholders from every sector to engage, innovate, and collaborate. Together, we can cultivate a more resilient agricultural landscape, where the benefits of combined rice mills reach beyond economic growth to nourish communities and foster sustainability. As we close the chapter on this exploration, may we embrace the insights gained and continue to champion the advances in our agricultural practices—unlocking potential, one grain at a time.