Unlocking Innovation: The Evolution of Chinese Rice Mills

Throughout centuries, rice has been more than just a staple food; it embodies the essence of culture, tradition, and innovation, particularly in China, where its cultivation dates back thousands of years. As one of the world’s largest producers of rice, the evolution of Chinese rice mills reflects a fascinating journey of technological advancement and sustainable practices. From humble beginnings, where hand-operated tools shaped the grain, to the modern, automated facilities that embody cutting-edge technology, the story of rice milling in China is a testament to human ingenuity and adaptability. This article delves into the transformation of rice mills across the nation, exploring how innovation has not only increased productivity but has also helped forge a path toward a more sustainable agricultural future. Join us as we unlock the layers of this intriguing evolution, revealing the pivotal role that rice mills play in both the economy and the daily lives of millions.

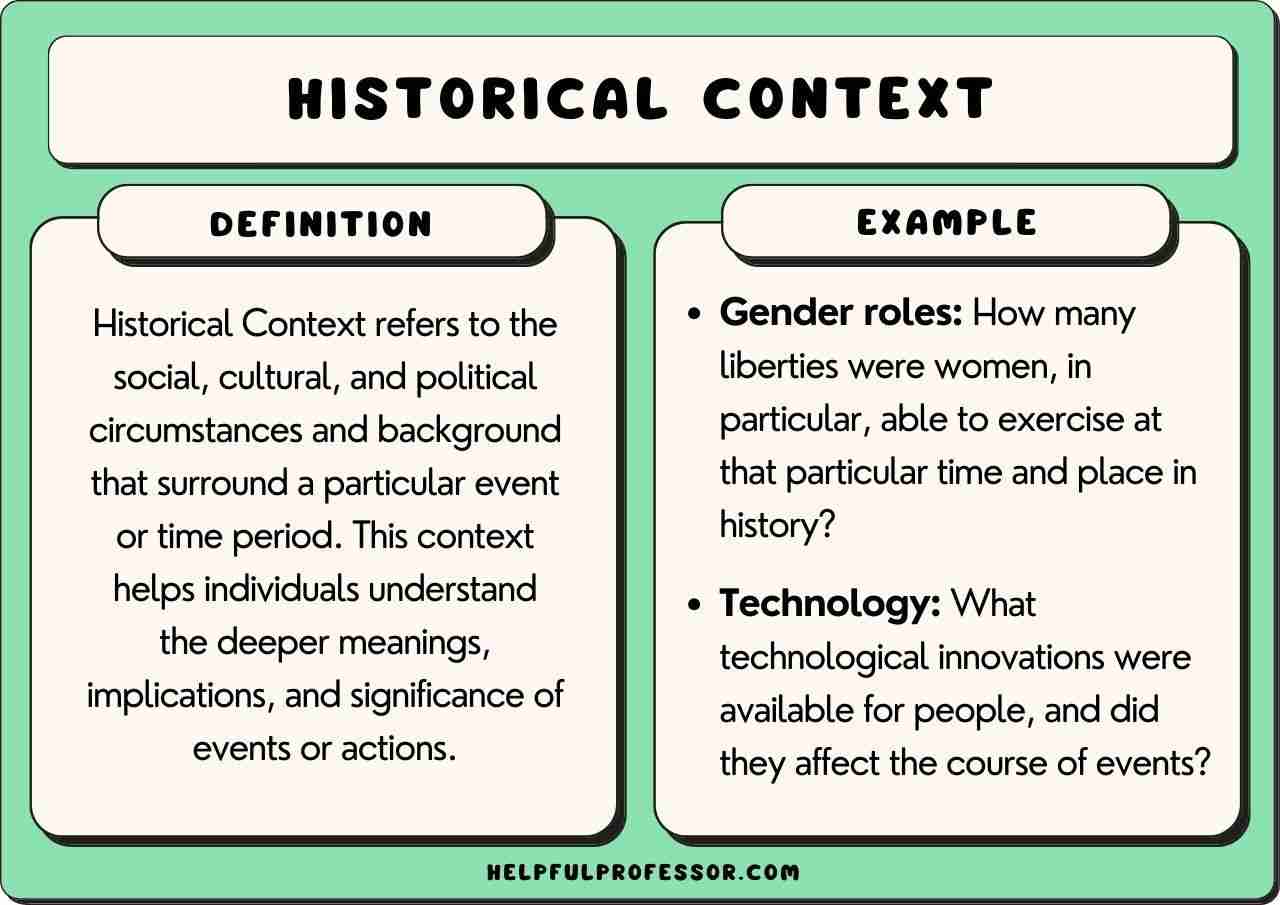

Understanding the Historical Context of Rice Milling in China

To truly appreciate the evolution of rice milling in China, one must delve into the rich tapestry of its historical context. For thousands of years, rice has not merely been a staple; it has served as the foundation of agricultural practices, culture, and social structure. The earliest records indicate that rice cultivation began around 10,000 years ago in the Yangtze River Valley, where the methods of processing rice were rudimentary at best. As Chinese society evolved, so did the technologies employed in rice milling, transitioning from manual processes utilizing stone grinding wheels to more sophisticated systems during the Tang and Song dynasties. The introduction of water mills during this period represented a significant advancement, dramatically increasing efficiency and altering the socio-economic landscape.

The impact of rice milling technology on Chinese society cannot be overstated. It not only influenced agricultural productivity but also shaped trade and urbanization. As cities expanded, the demand for processed rice surged, leading to innovations in milling techniques. Key developments included:

- Foot-powered mills: These mills allowed for more consistent output and were easier to operate than manual methods.

- Water-powered devices: Harnessing flowing water further revolutionized milling efficiency.

- Steam-powered mills (19th century): They marked the industrial revolution’s arrival in Chinese agriculture, enabling mass production.

The following table highlights some pivotal milestones in rice milling technology throughout Chinese history:

| Period | Milestone | Impact |

|---|---|---|

| Ancient Times | Initiation of manual milling | Foundation of rice processing |

| Tang/Song Dynasties | Introduction of water mills | Increased milling efficiency |

| 19th Century | Adoption of steam power | Mass production and urban growth |

As we explore these developments, it is evident that rice milling in China has not only been a reflection of agricultural advancement but also an indicator of the broader socio-economic shifts that have shaped the nation over millennia. The intertwining of tradition and innovation continues to influence rice milling practices today, maintaining its crucial role in the fabric of Chinese society.

Technological Advancements Transforming Production Efficiency

The landscape of rice milling in China has undergone a dramatic transformation, driven by cutting-edge technologies that have redefined traditional practices. Advanced automation solutions have liberated rice mills from labor-intensive methods, enabling them to streamline processes and significantly boost output. This shift allows mills to operate with remarkable precision, harnessing innovations such as real-time monitoring systems and intelligent sorting machines. These tools ensure unparalleled quality control, reducing waste and optimizing the production cycle.

Moreover, the integration of data analytics and artificial intelligence has brought about new levels of efficiency in resource allocation and operational management. By employing these technologies, rice mills can forecast demand, manage inventory more effectively, and implement predictive maintenance strategies. The data gleaned from these systems supports informed decision-making, driving continuous improvement within the production workflow. Notably, the following key advancements are at the forefront of this evolution:

- Automated Milling Processes – Accelerating production rates and decreasing labor dependency.

- AI-Driven Quality Assessment - Ensuring maximum consistency and reducing human error.

- Energy Management Solutions – Reducing costs and environmental impact through smarter energy use.

As we look at the journey of Chinese rice mills, it is evident that the fusion of technology and innovation is unlocking unprecedented levels of productivity. A recent evaluation of production metrics showcases these improvements:

| Year | Output (Tons) | Efficiency (%) |

|---|---|---|

| 2015 | 100,000 | 65 |

| 2020 | 150,000 | 80 |

| 2023 | 200,000 | 90 |

Embracing Sustainability: Future Directions for Rice Mills

As the landscape of rice milling continues to evolve, a robust commitment to sustainability emerges as a guiding principle for the industry. By leveraging advanced technology and innovative practices, rice mills are repositioning themselves to not only enhance productivity but also reduce their environmental footprint. Key strategies include:

- Water Conservation: Implementing efficient irrigation systems and recycling wastewater to minimize usage.

- Energy Efficiency: Utilizing renewable energy sources such as solar panels and biogas from rice husk to power operations.

- Waste Reduction: Developing new methods for repurposing byproducts, turning hulls and bran into biofuels and animal feed.

Moreover, collaborations with agricultural stakeholders can foster research and development aimed at resilient rice varieties that require less water and pesticide. Embracing precision agriculture techniques, rice mills can also support farmers in implementing sustainable practices, creating a holistic approach to rice production. The future will likely witness:

| Future Trends | Description |

|---|---|

| Smart Technologies | Integration of IoT and AI for real-time monitoring and optimization of milling processes. |

| Certifications | Adoption of eco-labeling to certify and promote sustainably milled rice. |

| Consumer Education | Initiatives to inform consumers about the benefits of sustainably produced rice. |

Strategies for Global Competitiveness in the Rice Market

To thrive in the competitive landscape of the global rice market, Chinese rice mills are adopting a multifaceted approach that emphasizes innovation and efficiency. Investing in advanced processing technologies has become a cornerstone of these strategies, allowing mills to enhance product quality while reducing operational costs. Additionally, leveraging data analytics to optimize supply chain management helps these businesses respond swiftly to changing market demands. The incorporation of renewable energy sources not only addresses sustainability concerns but also minimizes dependency on fossil fuels, paving the way for a more resilient operation.

Furthermore, strengthening international partnerships is pivotal in expanding market reach and improving competitiveness. By collaborating with global distributors and retailers, rice mills can gain valuable insights into consumer preferences and regional market trends. Establishing certification and quality assurance programs further positions Chinese rice as a premium product on the world stage. The following table illustrates some key strategies currently being implemented:

| Strategy | Description |

|---|---|

| Technology Integration | Utilizing advanced machinery for improved processing efficiency. |

| Data-Driven Supply Chain | Employing analytics to enhance logistics and inventory management. |

| Renewable Energy Use | Adopting solar and wind energy to power operations. |

| Global Collaboration | Forming alliances with international partners for distribution. |

| Quality Certification | Implementing standards to guarantee product quality and safety. |

Wrapping Up

As we conclude our exploration of the evolution of Chinese rice mills, it becomes evident that the journey of innovation has been as intricate and layered as the grains they process. From traditional methods steeped in history to cutting-edge technologies that promise efficiency and sustainability, these mills are a testament to the resilience and adaptability of the agricultural sector in China.

This transformation is not merely about modernization; it reflects a broader narrative of balance—between honoring age-old practices and embracing the future. With the world increasingly looking towards sustainable practices, the evolution of rice mills holds lessons not only for China but also for other nations striving for innovation in their agricultural practices.

As we look ahead, the fate of rice mills will undoubtedly continue to intertwine with advances in technology, environmental consciousness, and global market demands. The story of Chinese rice mills is still being written, and each new chapter brings fresh possibilities and challenges. Ultimately, the spirit of innovation will be crucial in shaping the future of rice production—not just in China, but across the globe.

Let us remain vigilant and inspired as we witness this ongoing revolution, where tradition meets innovation at the heart of an industry that nourishes millions.