Unlocking Grain Potential: The Journey of Rice Milling

In the heart of bustling markets and quiet rural landscapes alike, rice stands as a staple that nourishes populations around the globe. Its journey from paddy to plate is a remarkable transformation, intricately woven through the process of milling. This journey, often overlooked, holds the key to unlocking the grain’s full potential—enhancing its flavor, texture, and nutritional value. From the ancient techniques practiced in traditional mills to the advanced technology of modern processing facilities, rice milling is both an art and a science. As we delve deeper into this intricate process, we will explore the various stages of rice milling, the innovations driving the industry forward, and the impact on food quality and sustainability. Join us on this enlightening path as we uncover the secrets behind each grain and the vital role milling plays in feeding the world.

Exploring the Foundations of Efficient Rice Milling Techniques

Understanding the principles of efficient rice milling requires delving into both traditional practices and modern innovations. The milling process transforms paddy into edible rice, comprising several critical stages that can profoundly affect yield and quality. Key aspects to consider include:

- Pre-cleaning: Ensuring the removal of impurities such as dust, stones, and leaves to enhance the overall quality.

- Husking: The separation of the husk from the grain, which can be optimized through the use of adjustable husking machines.

- White Rice Production: Achieved by polishing the brown rice, wherein minimizing breakage becomes essential.

- Grading: Sorting the final product to guarantee a market-ready grade, maintaining consumer satisfaction.

Modern technology has led to the development of several machinery options, enabling more efficient milling processes. Employing automated systems can significantly reduce labor costs and enhance productivity. The following table showcases some common rice milling machines, along with their features and benefits:

| Machine Type | Key Features | Benefits |

|---|---|---|

| Husker | Adjustable speed and pressure settings | Reduced grain damage and higher quality output |

| Whitener | Gentle friction polishing | Enhanced aesthetic appeal of rice |

| Grader | Automated color sorting | Improved marketability and consumer trust |

Innovations in Machinery: Enhancing Grain Quality and Yield

As we delve into the transformative world of rice milling, remarkable advancements in machinery have emerged, setting new standards for grain quality and yield. Today’s milling technologies amplify efficiency through cutting-edge features that ensure minimal grain damage and maximum output. With the integration of precision sensors and automated systems, processors can monitor and adjust the milling process in real-time. This not only reduces waste but also directly improves the nutritional value of the final product. Innovations such as high-capacity huskers and foundry-quality rice whitener have enabled millers to achieve smoother finishes, helping communities leverage the nutritional benefits of high-quality rice.

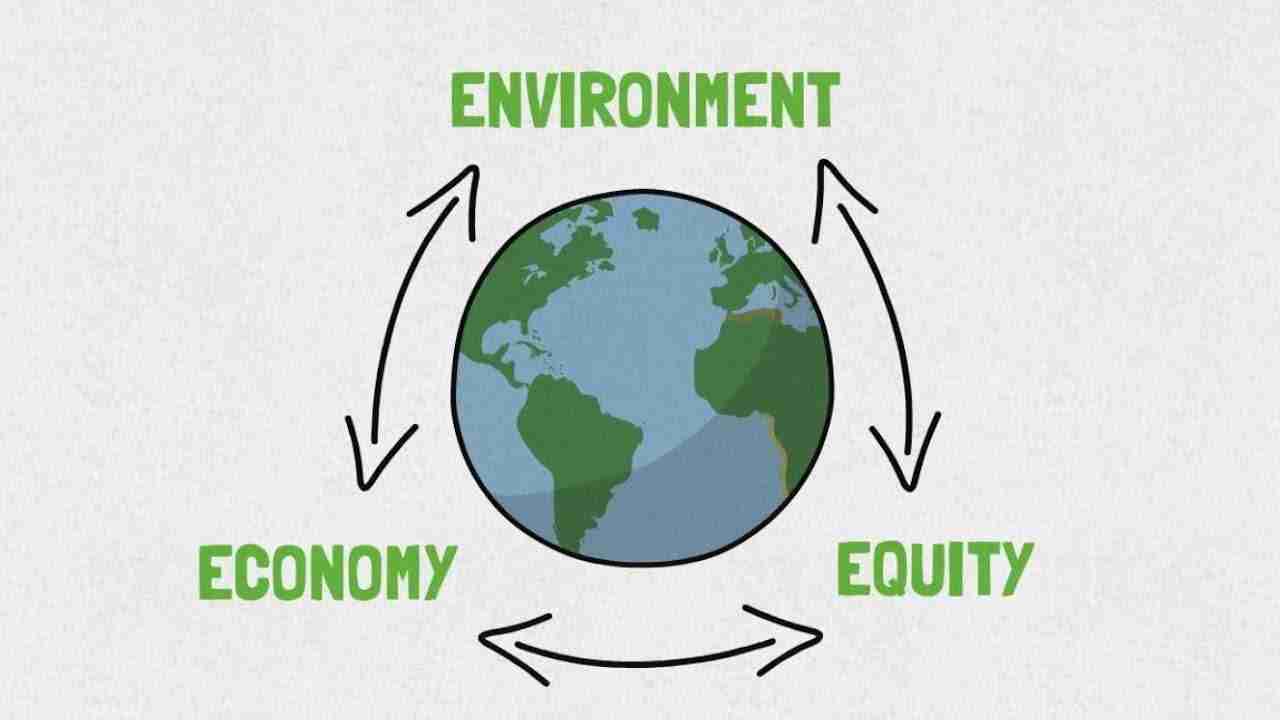

Moreover, the evolving landscape of machinery is underscored by the importance of sustainability. Eco-friendly milling solutions are now more prevalent, designed to lower energy consumption and minimize environmental impact. Increased use of biodegradable materials in machinery construction further supports this green initiative. Key components of modern rice mills are engineered to optimize performance whilst adhering to sustainable practices. The impact of these advancements can be summarized in the following attributes:

| Attribute | Description |

|---|---|

| Efficiency | Enhanced output with reduced downtime and waste. |

| Quality | Higher nutritional retention and better texture. |

| Sustainability | Lower carbon footprint with eco-friendly processes. |

Sustainability Practices in Rice Milling for a Greener Future

In the quest for a more sustainable approach to rice milling, many facilities are gradually adopting innovative practices that significantly reduce their environmental footprint. Key initiatives include the utilization of renewable energy sources, such as solar and biomass, which can power milling processes while decreasing dependency on fossil fuels. Additionally, embracing water conservation techniques not only minimizes consumption but also enhances the efficiency of operations:

- Implementing closed-loop water systems to recycle water used in milling

- Investing in advanced filtration technologies to treat and reuse water

- Integrating rainwater harvesting to supplement water supply

Moreover, the adoption of eco-friendly practices is reshaping waste management within the rice milling industry. The practice of using by-products to generate income and reduce waste is becoming increasingly popular:

| By-Product | Application |

|---|---|

| Rice Husk | Bioenergy production and as a soil amendment |

| Broken Rice | Animal feed or processed into rice flour |

| Rice Bran | Extracted for oil or used in health supplements |

These practices not only enhance profitability but also contribute to a circular economy, highlighting the potential of rice milling to support a greener future. By focusing on sustainable methods, millers can ensure that their operations contribute positively to both the local community and the planet.

The Role of Technology in Streamlining Rice Processing Operations

The integration of advanced technology in rice processing has not only enhanced efficiency but has also fundamentally transformed the quality and output of rice milling operations. With the advent of Automated Sorting Systems, millers can now separate whole grains from broken ones with remarkable precision. These systems utilize sophisticated algorithms and sensors to detect minute differences in shape, size, and color, ensuring that only the highest quality grains proceed through the milling process. Moreover, smart moisture meters play a pivotal role in maintaining the ideal moisture content, reducing the risk of spoilage and enhancing the shelf life of the final product.

Furthermore, digital monitoring technologies are redefining how rice milling facilities manage their operations. Real-time data analytics provide insights into machine performance, allowing for predictive maintenance that minimizes downtime and optimizes production schedules. Cloud-based management systems facilitate seamless communication across various departments, making it easier for teams to respond promptly to any issues that may arise. To illustrate the impact of technology on rice processing, consider the following table that highlights key technological innovations and their benefits:

| Technology | Benefits |

|---|---|

| Automated Sorting Systems | Increased efficiency and quality control |

| Smart Moisture Meters | Prevention of spoilage and enhanced shelf life |

| Digital Monitoring Technologies | Predictive maintenance and operational optimization |

| Cloud-based Management Systems | Improved communication and issue resolution |

Future Outlook

As we conclude our exploration of the intricate journey of rice milling, it becomes evident that this age-old process is more than just a means to an end. It represents a delicate balance of tradition and innovation, where each grain carries with it the promise of nourishment and prosperity. From the lush paddies that cradle the rice seeds to the meticulous techniques employed in milling, we have witnessed how every step plays a pivotal role in unlocking the full potential of this staple food.

In a world ever more focused on sustainability and efficiency, the rice milling industry stands at a crossroads, poised to embrace advancements that honor its roots while paving the way for future generations. As consumers, our choices can foster a deeper appreciation for the farmers, millers, and communities behind each bite of rice we enjoy.

Let us celebrate this journey, recognizing that in each grain lies the story of resilience, culture, and the ongoing pursuit of excellence. The journey of rice milling continues, shaping not only the grains we consume but also the very fabric of societies worldwide. Here’s to unlocking potential—one grain at a time.