Unlocking Efficiency: The Future of Combined Rice Mill Machines

In an era where efficiency reigns supreme across every industry, the agriculture sector stands on the brink of a revolutionary transformation. Among the most critical staples of global food security, rice has long sustained billions, but its processing has often lagged behind the innovations seen in other fields. Enter the combined rice mill machines—advanced solutions that promise to streamline operations, reduce production costs, and enhance overall quality. This article delves into the evolution of these multifaceted machines, exploring how they not only tackle the challenges of modern rice milling but also shape the future of agribusiness. Join us as we unlock the potential of combined rice mill machines and examine their vital role in redefining efficiency in rice processing.

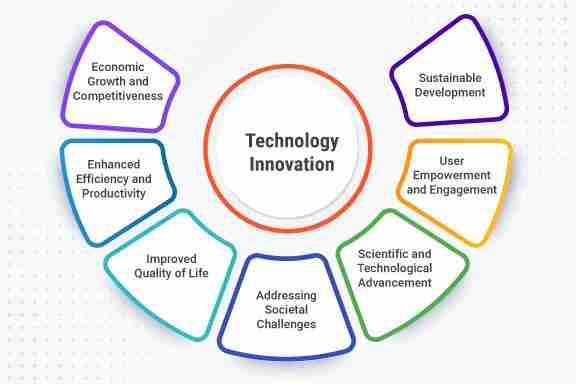

Exploring Technological Innovations in Combined Rice Mill Machines

In recent years, the rice milling industry has embraced remarkable advancements that have transformed traditional operations into highly efficient processes. The integration of automation technology is at the forefront of this evolution, allowing mills to optimize their production while minimizing labor costs. Modern combined rice mill machines are now equipped with features such as:

- IoT Connectivity: Enables real-time monitoring and control of milling operations.

- Energy Efficiency: Reduces power consumption with optimized machinery designs.

- Modular Design: Facilitates easy upgrading and maintenance without significant downtime.

Furthermore, these machines have started incorporating advanced data analytics to enhance the milling process. By analyzing grain characteristics and environmental conditions, operators can make data-driven decisions to improve yields and quality. Additionally, the development of eco-friendly technologies is gaining momentum, with features such as:

- Waste Recovery Systems: Convert by-products into valuable resources.

- Low Emission Solutions: Reduce the environmental footprint of rice milling.

- Water Recycling Units: Ensure sustainable water use during processing.

| Feature | Benefit |

|---|---|

| IoT Integration | Real-time monitoring |

| Energy Efficiency | Reduced operational costs |

| Waste Recovery | Utilization of by-products |

As these technological innovations continue to shape the industry, the future of combined rice mill machines looks promising. By harnessing the power of technology, mill operators can achieve unprecedented efficiency and sustainability, propelling the rice milling sector into a new era of productivity and eco-friendliness.

Enhancing Productivity Through Automation and Smart Integration

Embracing automation and smart integration within rice mill operations can dramatically elevate productivity levels. By deploying advanced technologies like IoT sensors, machine learning algorithms, and AI-driven analytics, rice mills can streamline their processes, reducing downtime and minimizing waste. Integration of various machinery, such as de-huskers, separators, and polishers into cohesive units, not only simplifies operations but also enhances the quality of the final product. Furthermore, automation can significantly reduce the need for manual labor, allowing operators to focus on more strategic tasks that drive overall efficiency.

A well-designed system, combining both automation and smart integration, results in a seamless production environment. Key aspects to consider include:

- Real-time Monitoring: Constant oversight of operational parameters ensures optimal performance and timely interventions.

- Data Integration: Centralizing data from different machines provides insights for predictive maintenance and efficiency improvements.

- Automated Workflow: Streamlined processes reduce bottlenecks and enhance processing speed.

| Feature | Benefit |

|---|---|

| IoT Sensors | Enhanced monitoring and predictive analytics |

| Automated Controls | Reduced manual intervention and error rate |

| Integrated Systems | Improved workflow and consistent product quality |

Sustainable Practices for Eco-Friendly Rice Milling

As the global demand for sustainable practices grows, eco-friendly rice milling has emerged as a pivotal point in the agricultural sector. By adopting renewable energy sources such as solar and biogas for power generation, rice mills can significantly reduce their carbon footprint. Additionally, implementing water recycling systems not only conserves vital resources but also minimizes wastewater discharge into surrounding ecosystems. These measures are enhanced by the use of energy-efficient machinery designed to optimize output while reducing energy consumption through innovative technology.

Incorporating organic waste management techniques marks another crucial step toward sustainable rice milling. For example, instead of discarding husks and bran, mills can utilize these by-products to create organic fertilizers or biomass energy, fostering a circular economy within the industry. Furthermore, the introduction of smart technology to monitor and adjust machinery settings in real-time helps to limit excess energy consumption, thus driving efficiency. The integration of such practices not only meets consumer expectations for sustainability but also sets a benchmark for future innovations in rice processing.

Future Trends and Market Prospects for Rice Milling Equipment

As the demand for rice continues to grow globally, the rice milling equipment market stands poised for significant transformation. With advancements in technology and increased focus on sustainability, manufacturers are keen to integrate features that enhance efficiency and reduce environmental impact. Key trends include the integration of smart technologies such as Internet of Things (IoT) devices, which allow for real-time monitoring and optimization of milling processes. These innovations not only improve functionality but also minimize resource consumption, making operations more efficient. Furthermore, manufacturers are increasingly adopting modular designs, enabling scalability and flexibility as market needs evolve.

Market prospects look bright as industry players recognize the importance of moving toward automation and intelligent machinery. Emerging markets, particularly in Asia and Africa, are investing in modern rice milling technologies to boost their agricultural outputs. Additionally, the shift towards organic and sustainably sourced rice products is encouraging the development of equipment designed to process these grains effectively. Potential advancements that may redefine the landscape include:

- AI-powered analytics to analyze production data and suggest improvements.

- Energy-efficient motors reducing electricity consumption significantly.

- Enhanced safety features ensuring a safer working environment.

To illustrate the expected growth in demand for various types of rice milling equipment over the next five years, the following table summarizes the projected market values:

| Year | Market Value (in USD million) | Growth Rate (%) |

|---|---|---|

| 2024 | 150 | 5 |

| 2025 | 158 | 5.3 |

| 2026 | 166 | 5.5 |

| 2027 | 175 | 5.7 |

| 2028 | 185 | 6 |

To Conclude

As we stand on the brink of a new era in agricultural technology, the future of combined rice mill machines shines brightly with the promise of efficiency, sustainability, and innovation. These advanced systems not only streamline the rice milling process but also empower farmers and millers to maximize yields while minimizing waste. By embracing these cutting-edge solutions, we are not merely transforming how rice is processed; we are paving the way for a more resilient and food-secure world.

As we look forward, the integration of smart technology, automation, and eco-friendly practices will continue to redefine the landscape of rice milling, ensuring that the heart of our agricultural industry beats with enhanced productivity and reduced environmental impact. The journey towards unlocking efficiency is just beginning, and the possibilities are as vast as the fields of golden grain awaiting harvest. Let us remain curious, adaptable, and committed to innovation, for it is through collaboration and creativity that we will craft a brighter future for rice milling and global food production.