In the world of food production, efficiency is key. Nowhere is this more evident than in the rice milling industry, where the intricate process of turning raw rice into polished grains requires seamless integration of technology and manpower. In this article, we delve into the ultimate rice mill integration, exploring how streamlining production can revolutionize the way rice is processed and ultimately, consumed. Join us as we uncover the secrets to maximizing efficiency and quality in rice milling, taking your production to the next level.

Heading 1: Advantages of Implementing an Integrated Rice Mill System

Implementing an integrated rice mill system offers a plethora of advantages that can revolutionize the production process. One key benefit is the efficiency gained through automation and centralization of operations. By incorporating all stages of rice milling into a single, seamless system, tasks such as cleaning, husking, and polishing can be completed with minimal human intervention, reducing labor costs and increasing output.

Furthermore, an integrated rice mill system allows for better quality control and consistency in the final product. With sensors and monitoring tools embedded throughout the production line, deviations in quality can be detected and rectified in real-time. This ensures that every batch of rice meets the desired standards, leading to higher customer satisfaction and increased market competitiveness.

Heading 2: Optimizing Workflow Efficiency through Automation

By integrating automation into the production process of a rice mill, businesses can significantly enhance their workflow efficiency. This streamlined approach allows for tasks to be completed faster and with a higher degree of accuracy, ultimately leading to increased productivity and reduced operational costs. Automation can handle repetitive tasks such as sorting and grading rice, freeing up valuable human resources to focus on more strategic aspects of the operation.

With automation in place, rice mills can ensure consistent quality in their output, reduce human error, and improve overall operational reliability. By leveraging technology such as sensors, robotics, and machine learning algorithms, rice mill operators can optimize their production processes and maximize output. Additionally, automation can also help in monitoring and maintaining equipment, ensuring that downtime is minimized and that production runs smoothly.

Heading 3: Key Components for a Successful Rice Mill Integration

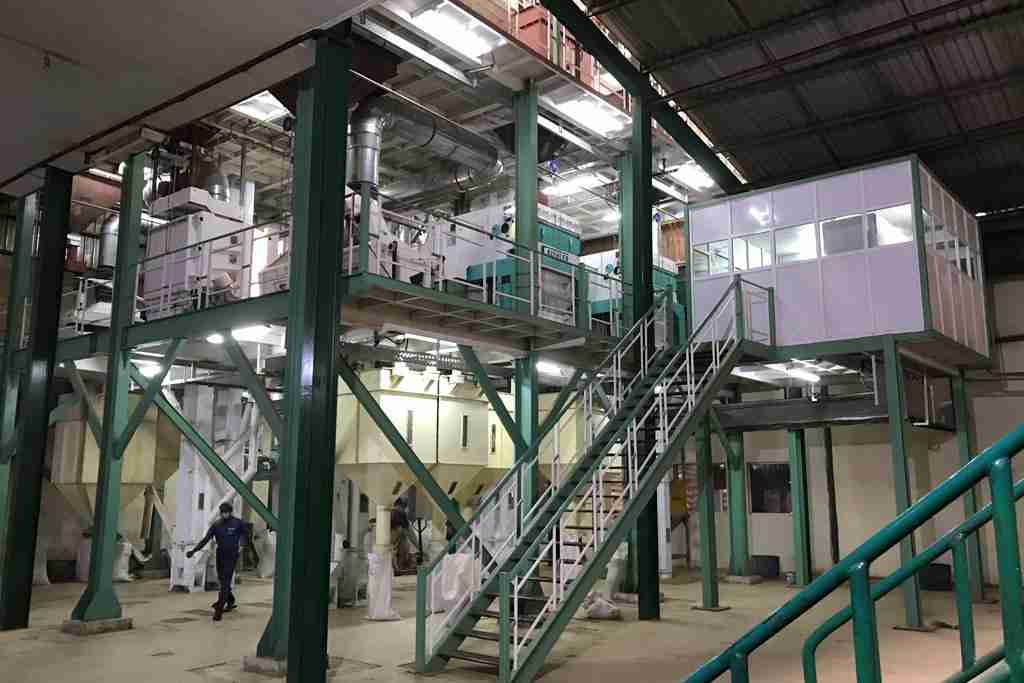

When aiming for a successful rice mill integration, it is crucial to focus on key components that streamline production and enhance efficiency. One essential component is **automated machinery**, such as state-of-the-art rice milling equipment that can handle large volumes of grains with precision and speed. Investing in top-quality machinery ensures consistent output and reduces operational downtime.

Another vital aspect of rice mill integration is **inventory management software**. This technology helps in monitoring rice stocks, tracking production levels, and managing supply chain logistics effectively. By utilizing advanced software solutions, rice millers can optimize inventory control, minimize wastage, and improve overall production planning.

Heading 4: Enhancing Quality Control and Traceability in Rice Production

By implementing cutting-edge technology and innovative practices, rice producers can revolutionize their operations and achieve a new level of efficiency. One key aspect of this transformation is the integration of digital tools and data management systems to enhance quality control and traceability throughout the entire rice production process. With real-time monitoring and analytics, producers can identify areas for improvement, optimize resource allocation, and ensure that every batch of rice meets the highest standards of quality.

Furthermore, streamlining production through automation and smart machinery can significantly reduce manual labor and human error, ultimately leading to higher yields and cost savings. By investing in state-of-the-art equipment and adopting advanced farming techniques, rice producers can optimize their workflow, minimize waste, and deliver superior products to consumers worldwide. The ultimate goal is to create a seamless and efficient production cycle that prioritizes quality control and traceability at every step of the process.

In Conclusion

In conclusion, the integration of a rice mill can revolutionize the production process, making it more efficient and streamlined than ever before. By investing in advanced technology and automation, rice millers can enhance their output and quality, ultimately leading to increased profitability and success. With the ultimate rice mill integration, the possibilities are endless. Embrace the future of rice milling and watch your business flourish like never before.