In the bustling world of agriculture, the 5 Ton Rice Mill stands as a beacon of efficiency and productivity. With its powerful capabilities and advanced technology, this ultimate rice milling machine has revolutionized the process of turning raw rice into polished grains. Join us on a detailed exploration of the inner workings and impressive features of the 5 Ton Rice Mill, as we uncover the secrets behind its unparalleled performance and unmatched precision.

Title: The Ultimate 5 Ton Rice Mill: A Detailed Overview

When it comes to maximizing efficiency and output in the rice milling process, the ultimate 5 ton rice mill is a game-changer. This state-of-the-art machine is designed to handle large quantities of rice with precision and speed, making it ideal for commercial rice milling operations.

With advanced features such as automated grain feeding, high-speed milling, and precision sorting, the 5 ton rice mill streamlines the entire rice production process. Its robust construction and durable components ensure reliable performance, while its user-friendly interface makes operation simple and intuitive. Investing in the ultimate 5 ton rice mill is a smart choice for any business looking to increase productivity and quality in their rice milling operations.

Overview of 5 Ton Rice Mill Operations

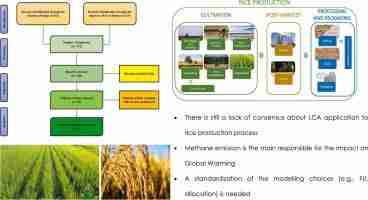

Operating a 5 ton rice mill requires meticulous attention to detail and a well-organized process. From receiving raw paddy to packaging the final product, each step in the operation plays a crucial role in ensuring the quality of the rice. The mill is equipped with state-of-the-art machinery that can handle large quantities of paddy efficiently, resulting in a high yield of processed rice.

The operation of a 5 ton rice mill involves several key tasks, including cleaning and destoning the paddy, husking and whitening the rice, and polishing and grading the final product. Each stage of the process requires skilled workers to monitor and adjust the machinery to achieve the desired outcome. Additionally, proper storage and packaging of the rice are essential to maintain its freshness and quality. With a well-designed operation and a dedicated team, a 5 ton rice mill can produce high-quality rice consistently.

Key Components and Features for Optimal Performance

When it comes to optimizing the performance of a 5-ton rice mill, there are several key components and features that play a crucial role in ensuring smooth operations and maximum output. One of the most important factors to consider is the quality of the milling chamber. A sturdy and durable milling chamber is essential for handling large quantities of rice efficiently, while also minimizing the risk of breakdowns or malfunctions.

Another key component for optimal performance is the precision of the milling mechanism. A high-quality milling mechanism with adjustable settings allows for precise control over the texture and quality of the final product, ensuring consistency and uniformity in each batch of rice. Additionally, a reliable cooling system is essential for maintaining the ideal operating temperature, preventing overheating and prolonging the lifespan of the mill.

Technological Advancements and Efficiency Improvements

When it comes to technological advancements in the agriculture industry, the 5 ton rice mill stands out as a shining example of efficiency and productivity. This state-of-the-art machine is equipped with cutting-edge automation technology that streamlines the entire rice milling process, from cleaning and husking to polishing and sorting. The advanced sensors and control systems ensure consistent output quality while minimizing waste, making it a game-changer for rice farmers and mill operators.

One of the key features of the 5 ton rice mill is its ability to process large quantities of rice in a relatively short amount of time. With a high milling capacity and rapid processing speed, this machine significantly increases overall efficiency and throughput. Additionally, the integrated software allows for real-time monitoring and adjustments, optimizing performance and reducing downtime. In a competitive market where time is money, investing in the ultimate 5 ton rice mill is a smart choice for businesses looking to stay ahead of the curve.

Recommendations for Maximizing Output and Quality

To maximize output and quality with the ultimate 5 ton rice mill, consider the following recommendations:

Operational Efficiency:

- Regular maintenance schedules to keep the mill running smoothly.

- Training for operators on best practices to optimize production.

- Implement automated processes for increased efficiency.

Quality Control:

- Regularly test rice samples for moisture content and purity.

- Invest in high-quality milling equipment for consistent results.

- Establish strict cleanliness protocols to prevent contamination.

The Way Forward

As we conclude our detailed overview of the ultimate 5 ton rice mill, we hope that you have gained valuable insight into the intricate world of rice processing. From the importance of efficient milling to the innovative technology that drives these machines, there is no doubt that these mills play a crucial role in the food industry. Whether you are a seasoned professional or a curious enthusiast, the journey to understanding the complexities of rice milling is both enlightening and rewarding. Thank you for joining us on this exploration, and we look forward to sharing more fascinating insights with you in the future. Until next time, happy milling!