In a world where technological advancements are reshaping industries at an unprecedented pace, the grain processing sector stands on the brink of transformation. At the heart of this metamorphosis lies the humble rice mill—an essential facility that has long been the backbone of food security in countless cultures. As global demands for efficiency, sustainability, and quality intensify, auto rice mills are emerging as the lifeblood of modern agriculture. This article delves into the innovative technologies and practices poised to revolutionize grain processing, exploring how automated systems can enhance productivity, reduce waste, and meet the ever-evolving needs of consumers. Join us on a journey to uncover the future of auto rice mills, where tradition meets innovation in a harmonious blend that promises to change the way we cultivate and process one of the world’s most vital staples.

Innovative Technologies Shaping the Next Generation of Auto Rice Mills

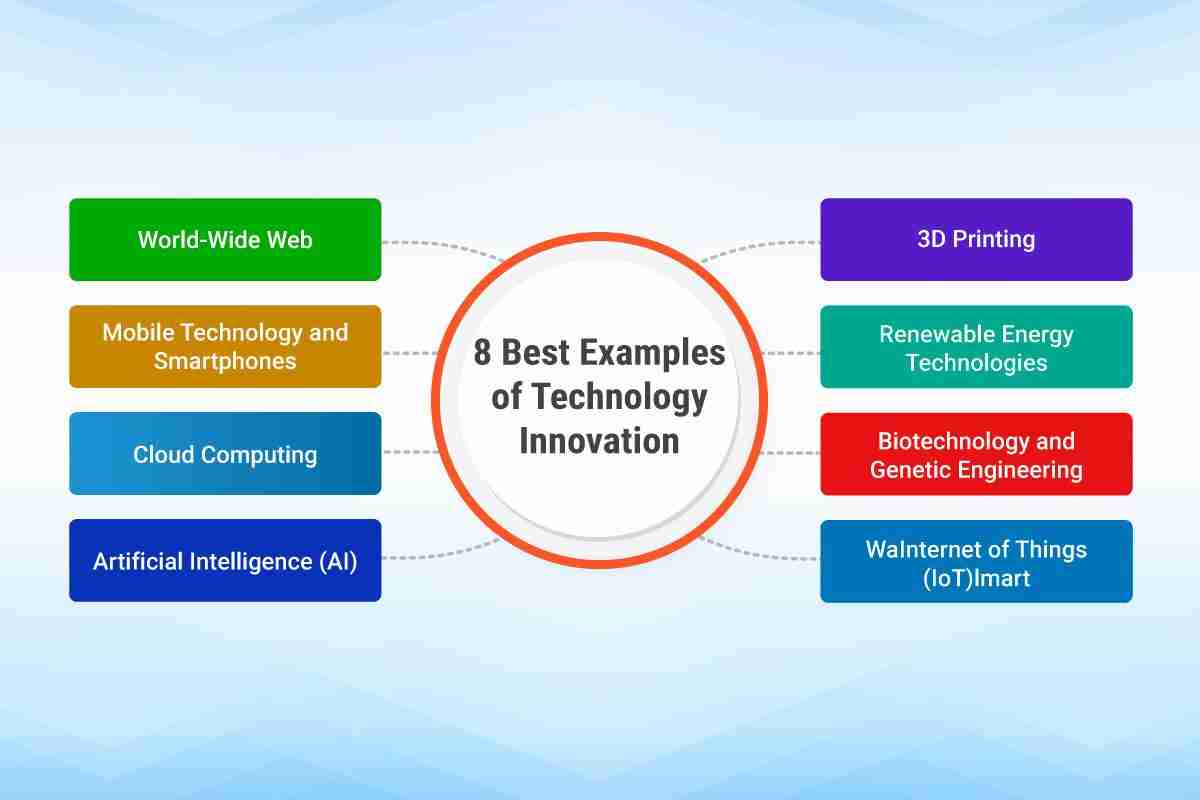

As the world embraces the digital age, the landscape of rice milling is undergoing a dramatic transformation through the integration of cutting-edge technologies. IoT-enabled sensors are now common, allowing mill operators to closely monitor the milling process in real-time. This technology not only enhances operational efficiency but also enables predictive maintenance, reducing downtime and maximizing productivity. Moreover, artificial intelligence algorithms are being employed to optimize milling parameters, ensuring that each grain is processed with precision, which ultimately leads to improved rice quality and yield.

The use of renewable energy sources is also becoming prevalent in auto rice mills, with solar panels and biomass energy systems powering operations sustainably. This shift is crucial not only for reducing environmental footprint but also for cutting operational costs over time. Additionally, advanced automation systems streamline workflows, from sorting and cleaning to milling and packaging, creating a seamless process that minimizes human error and enhances safety. With these innovations, the future of rice milling is poised for growth, efficiency, and sustainability, marking a significant step forward for the agricultural sector.

| Technology | Benefits |

|---|---|

| IoT Sensors | Real-time monitoring and predictive maintenance |

| AI Algorithms | Optimization of milling parameters for improved quality |

| Renewable Energy | Reduction of environmental impact and operational costs |

| Advanced Automation | Streamlined workflow, minimized errors, enhanced safety |

Sustainability Practices for a Greener Future in Rice Milling

As the world shifts towards eco-friendly practices, the rice milling industry is taking significant strides to embrace sustainability. The implementation of energy-efficient machinery reduces fossil fuel reliance, minimizing carbon footprints and enhancing operational efficiency. Auto rice mills are now integrating renewable energy sources such as solar panels and bioenergy systems, enabling them to harness sustainable power for their operations. Additionally, advanced technologies like moisture sensors and automated quality control not only optimize the milling process but also ensure that resources are used judiciously, drastically cutting down on waste and energy consumption.

Moreover, water conservation techniques are becoming an essential part of rice milling practices. Closed-loop water systems allow the reuse of water in various stages of milling, significantly decreasing overall water usage. The cultivation of rice varieties that require less water is also gaining traction, providing a double benefit of improved yield and sustainability. To illustrate the impact of these practices, the following table outlines some common eco-friendly innovations being adopted in the industry:

| Innovative Practice | Benefit |

|---|---|

| Energy-Efficient Machinery | Lower energy consumption and reduced emissions |

| Renewable Energy Sources | Decreased reliance on non-renewable fuels |

| Water Recycling Systems | Minimized water waste and lowered operational costs |

| Automated Quality Control | Improved efficiency and reduced processing errors |

Enhancing Efficiency Through Smart Automation and Data Analytics

The integration of intelligent systems and robust data analysis tools offers a transformative approach to optimizing processes in the rice milling industry. By leveraging smart automation, mills can streamline operations, reduce human error, and ensure consistent quality in their products. Innovations such as automated grading systems and robotic sorting machines not only minimize labor costs but also significantly enhance the speed and accuracy of processing. As these technologies evolve, they can provide real-time feedback and analytics, allowing managers to make informed decisions quickly, thus responding to market demands with agility.

In conjunction with automation, the use of data analytics plays a crucial role in redefining operational strategies. Creating a feedback loop that tracks metrics such as yield rates, energy consumption, and machine performance can uncover insights that drive efficiency. For instance, predictive analytics can forecast maintenance needs, enabling preventive measures that reduce downtime and extend equipment lifespan. The synergy of these technologies leads to sustainable practices that benefit not just the mills but also the larger agricultural ecosystem. Below are key features and benefits of implementing smart automation and data analytics in rice milling:

- Increased Productivity: Automation enables continuous operations and maximizes throughput.

- Enhanced Quality Control: Data analytics can help monitor and improve quality at each stage.

- Cost Savings: Reduced labor and improved resource management lower overall operating costs.

- Sustainability: Efficient processes lead to less waste and better resource utilization.

Consider the following comparative advantages of traditional mills versus automated rice mills:

| Feature | Traditional Mills | Automated Mills |

|---|---|---|

| Processing Speed | Moderate | High |

| Error Rate | Higher | Lower |

| Data Insights | Limited | Extensive |

| Maintenance Predictability | Reactive | Proactive |

Market Trends and Consumer Demand Driving Change in Grain Processing

The landscape of grain processing is rapidly evolving, driven by dynamic market trends and the shifting demands of consumers. As health-conscious customers increasingly seek organic, whole-grain options, processors are compelled to adapt their methods and technologies to align with these preferences. The rise of plant-based diets and an emphasis on sustainable sourcing have further intensified pressure on producers to innovate. Operators of auto rice mills are now exploring advanced milling technologies that not only enhance operational efficiency but also preserve the nutritional quality of the grain. This shift is re-defining grain processing, encouraging the incorporation of modern practices that ensure minimal waste while maximizing output.

Moreover, the integration of automation and smart technology stands at the forefront of this transformation. Auto rice mills are harnessing the power of data analytics and IoT (Internet of Things) applications to optimize production processes. These technologies enable producers to monitor grain quality in real-time, ensuring each batch meets consumer standards. Some key factors driving this change include:

- Technological Innovation: Implementation of AI-driven machinery.

- Consumer Preferences: Higher demand for specialty rice varieties.

- Sustainability Initiatives: Reduction of energy consumption.

The future of grain processing in the context of auto rice mills looks promising, as producers harness these emerging trends to cater to a more discerning market. The inclusion of holistic consumer insights and a commitment to sustainable practices could define the next generation of grain processing, fostering a landscape ripe for innovation and growth.

Future Outlook

As we stand on the precipice of agricultural innovation, the future of auto rice mills beckons with promise and potential. By embracing cutting-edge technology, sustainable practices, and a commitment to efficiency, the grain processing industry is poised for a transformation that will not only increase productivity but also enhance the quality and accessibility of rice around the globe.

The revolution in grain processing is more than just a technological shift; it represents a paradigm change in how we approach food security, environmental stewardship, and economic resilience. As auto rice mills continue to evolve, they will redefine the relationship between farmers, consumers, and the land itself, paving the way for a more sustainable future.

Ultimately, the journey of auto rice mills is a narrative of adaptability and progress, one that encourages us to imagine a world where innovation meets tradition. As we move forward, let’s remain alert to the opportunities that lie ahead and the ways in which these advancements can bridge the gap between what we produce and what we need. Together, we are writing a new chapter in the story of grain—a chapter where the future is not only bright but also bountiful.