In the bustling markets of rural villages, the rhythmic hum of small rice mills fills the air, transforming grains of rice into nourishing sustenance. These unassuming machines are the unsung heroes of agriculture, playing a crucial role in ensuring food security for communities around the world. Join us as we delve into the world of small rice mills and explore their efficiency in turning grains to gains.

Overview of Small Rice Mills Efficiency

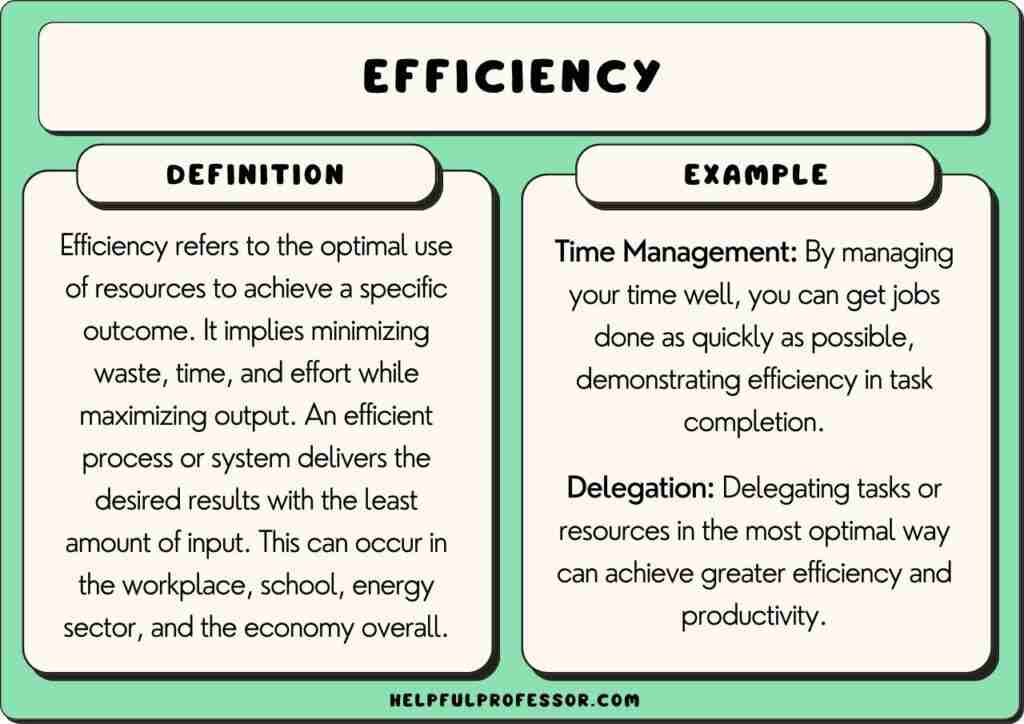

When it comes to small rice mills, efficiency is key in maximizing output and profitability. These compact machines play a crucial role in processing rice grains into market-ready products. Understanding the factors that influence their efficiency can help rice mill operators optimize their operations and achieve better returns on investment.

Factors that contribute to the efficiency of small rice mills include technology and machinery used, operators’ skills and knowledge, maintenance and upkeep of equipment, and processing capacity and speed. By focusing on these areas, rice mill owners can improve their output quality, reduce processing time, and ultimately increase their bottom line. Investing in modern equipment, providing training for operators, and implementing regular maintenance schedules are just a few ways to enhance the efficiency of small rice mills.

Challenges Faced by Small Rice Mills

Small rice mills play a crucial role in the agricultural industry, but they are not without their challenges. One major obstacle faced by these mills is the lack of modern equipment and technology. Many small rice mills rely on outdated machinery, which can lead to inefficiencies and higher production costs. Without access to the latest technology, these mills struggle to compete with larger, more advanced facilities.

Another challenge faced by small rice mills is the fluctuating market prices. Price volatility in the rice market can have a significant impact on the profitability of these mills. Small rice mill owners often find themselves at the mercy of market forces, struggling to navigate the ever-changing landscape of supply and demand. To stay competitive, small rice mills must find ways to adapt to these fluctuations and find new opportunities for growth.

| Challenge | Solution |

|---|---|

| Lack of modern equipment | Invest in upgrading machinery to improve efficiency |

| Price volatility | Diversify product offerings to mitigate the impact of market fluctuations |

Recommendations for Improving Efficiency in Small Rice Mills

When it comes to improving efficiency in small rice mills, there are several key recommendations that can make a significant impact on operations. One important strategy is to invest in modern technology, such as automated milling equipment, to streamline the production process. By utilizing machinery that can handle tasks like cleaning, dehusking, and polishing rice, mills can greatly increase their output and reduce labor costs.

Another recommendation for small rice mills looking to boost efficiency is to implement proper maintenance and regularly inspect all machinery to ensure smooth operation. Keeping equipment in good working condition helps prevent breakdowns and delays in production. Additionally, training staff on best practices and efficient techniques can also contribute to overall productivity. By focusing on these recommendations, small rice mills can maximize their efficiency and profitability in the competitive market.

Exploring Alternative Technologies for Small Rice Mills

Small rice mills play a crucial role in processing rice for consumption, but as technology advances, exploring alternative technologies can lead to increased efficiency and productivity. From manual processing to mechanized solutions, there are various options available for small rice mill owners to consider.

One alternative technology worth exploring is the use of modern rice milling machines, which can significantly reduce processing time and increase overall yield. Additionally, implementing automation in the milling process can help streamline operations and reduce manual labor. Investing in solar-powered solutions can also be a sustainable option for small rice mills, reducing electricity costs and environmental impact.

Wrapping Up

In conclusion, the small rice mills play a crucial role in the agricultural industry by efficiently processing grains to help farmers gain maximum yield. As technology advances, it is essential for these mills to continue exploring innovative methods to improve their efficiency and productivity. By doing so, they can contribute to the overall growth and sustainability of the rice production process. With continuous research and development, small rice mills can further optimize their operations and pave the way for a more prosperous and sustainable future in the agricultural sector.